Filter material with sterilization function and preparation method of filter material

A filter material and function technology, applied in the field of non-centralized sterilization and water purification, can solve the problems of short service life and low sterilization efficiency, and achieve the effects of easy material, high production efficiency and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

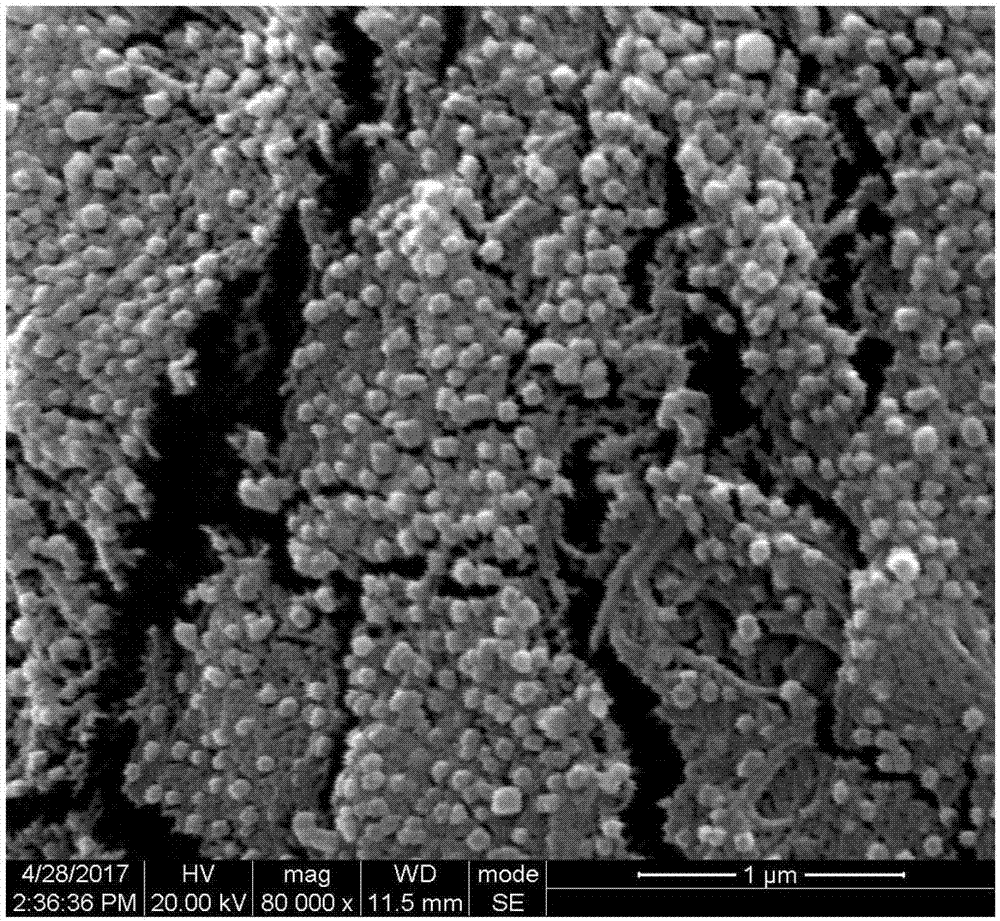

Image

Examples

Embodiment 1

[0030] The preparation method of the filter material with bactericidal function of the present embodiment is as follows:

[0031] 1) Obtaining a filter matrix: the filter matrix is fiber filter paper with a pore size of 40 μm.

[0032] 2) load sterilization layer

[0033] S1: Prepare the first mixed solution: the solvent of the first mixed solution is water, and the solute is glucose and silver nitrate, wherein the concentration of the glucose is 1 mol / L, and the concentration of the silver nitrate is 25 mmol / L.

[0034] S2: Put the filter matrix into the first mixed solution for the first soaking, and the soaking time is 30 minutes.

[0035] S3: Put the soaked filter base into an oven, react at 80° C. for 70 minutes, and then rinse, that is, load a bactericidal layer on the pore surface of the filter base to obtain an intermediate.

[0036] 3) Load fixed layer

[0037] S1: Prepare the second mixed solution: the solvent of the second mixed solution is water, and the solute ...

Embodiment 2

[0043] The preparation method of the filter material with bactericidal function of the present embodiment is as follows:

[0044] 1) Obtaining a filter matrix: the filter matrix is fiber filter paper with a pore size of 40 μm.

[0045] 2) load sterilization layer

[0046] S1: Prepare the first mixed solution: the solvent of the first mixed solution is water, the solute is glucose and silver nitrate, wherein the concentration of the glucose is 1mol / L, and the concentration of the silver nitrate is 50mmol / L.

[0047] S2: Put the filter matrix into the first mixed solution for the first soaking, and the soaking time is 25 minutes.

[0048] S3: put the soaked filter base into an oven, react at 90° C. for 60 min, and then rinse, that is, load a sterilizing layer on the pore surface of the filter base to obtain an intermediate.

[0049] 3) Load fixed layer

[0050] S1: Prepare the second mixed solution: the solvent of the second mixed solution is water, and the solute is chitos...

Embodiment 3

[0056] The preparation method of the filter material with bactericidal function of the present embodiment is as follows:

[0057] 1) Obtaining a filter matrix: the filter matrix is fiber filter paper with a pore size of 40 μm.

[0058] 2) load sterilization layer

[0059] S1: Prepare the first mixed solution: the solvent of the first mixed solution is water, the solute is glucose and silver nitrate, wherein the concentration of the glucose is 1mol / L, and the concentration of the silver nitrate is 75mmol / L.

[0060] S2: Put the filter matrix into the first mixed solution for the first soaking, and the soaking time is 20 minutes.

[0061] S3: put the soaked filter base into an oven, react at 95° C. for 50 min, and then rinse, that is, load a bactericidal layer on the pore surface of the filter base to obtain an intermediate.

[0062] 3) Load fixed layer

[0063] S1: Prepare the second mixed solution: the solvent of the second mixed solution is water, and the solute is chito...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com