Range hood hot blowing cleaning system

A technology of cleaning system and hot air outlet, which is applied in the direction of removing oil fume, drying machine, household heating, etc., and can solve the problems that the range hood needs to be disassembled and cleaned, cleaning is inconvenient, and sewage pollutes the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

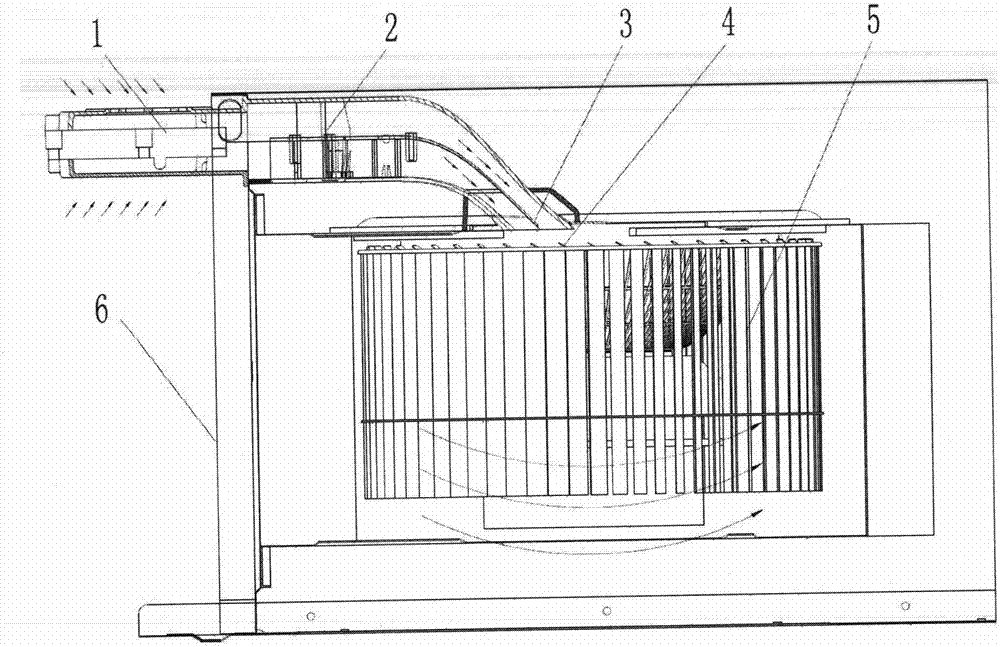

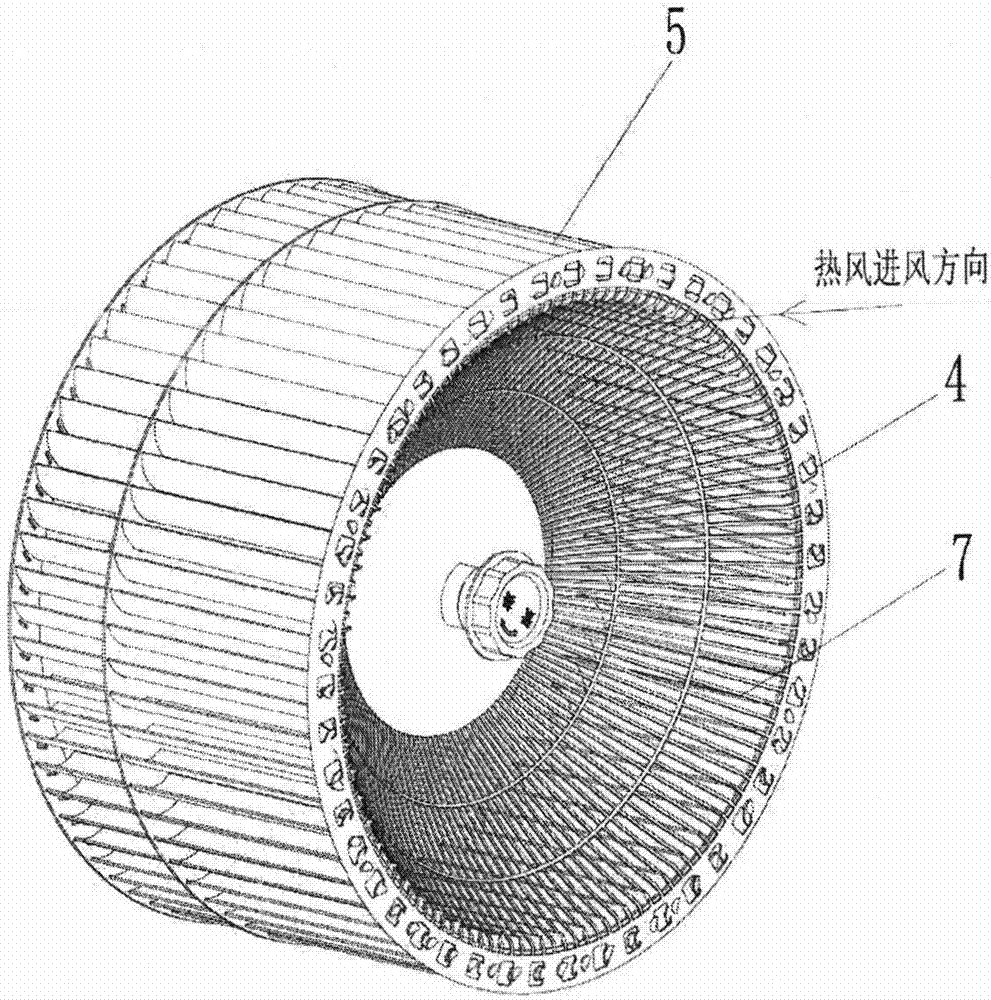

[0018] Embodiment: a kind of range hood hot blowing cleaning system, such as figure 1 shown. The device includes a body 6, which is provided with an impeller 5 rotating around a rotating shaft, a motor is arranged at the rear of the rotating axis of the impeller, and axially extending impeller blades are evenly arranged on the circumference of the impeller, and the impeller blades are involute-shaped arcs blade. The front side of the impeller is perpendicular to the rotation axis, and the front side of the impeller is the suction side. The side of the front side top of the body 6 is provided with a cleaning fan 1, and the cleaning fan is connected with an electric heating device 2, and the electric heating device is a ceramic chip PTC heating device. The electric heating device is connected to the hot air outlet 3, and the hot air outlet 3 is aligned with the top of the vertical centerline of the front side of the impeller. The air outlet position of the hot air outlet is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com