A fully automatic drilling production equipment for furniture panels

A kind of production equipment and fully automatic technology, applied in the direction of drilling machines, manufacturing tools, wood processing equipment, etc., can solve the problems of large labor consumption, error-prone, restricting production efficiency, etc., and achieve the effect of saving labor costs and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings.

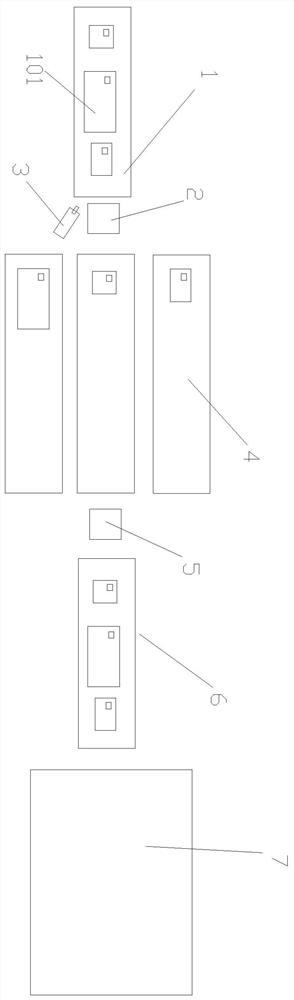

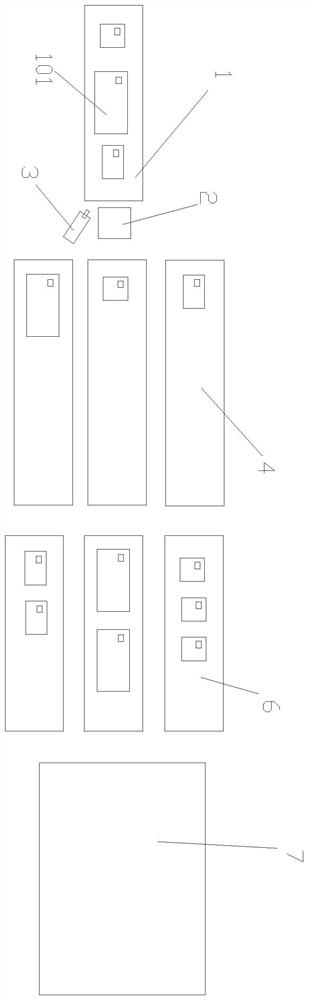

[0025] see figure 1 , the present invention provides a fully automatic drilling production equipment for furniture boards, including a control system, a feeding and conveying device 1, a sorting device 2, a high-speed code reading device 3, a board processing station 4, a handling device 5, and a discharging device 6 And packaging storage station 7. The feeding and conveying device 1 is used to convey furniture panels 101 of various sizes. Labels are pasted on the furniture panels 101, and the information of the corresponding panels is recorded on the labels, including appearance, size specifications, positions of holes to be processed, and installation positions. Wait. During the conveying process of the boards on the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com