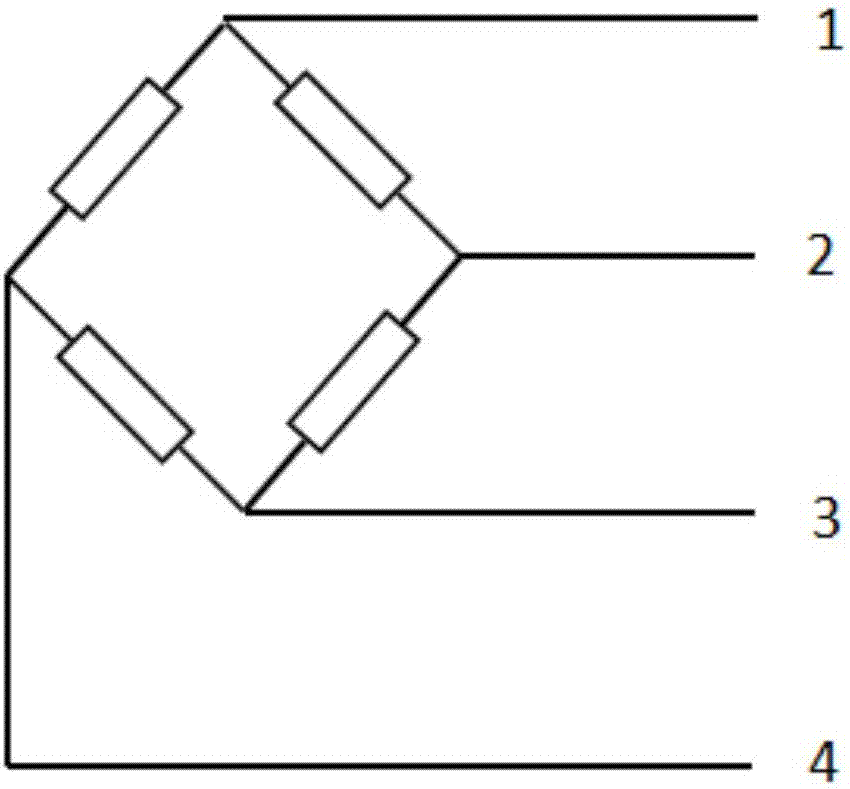

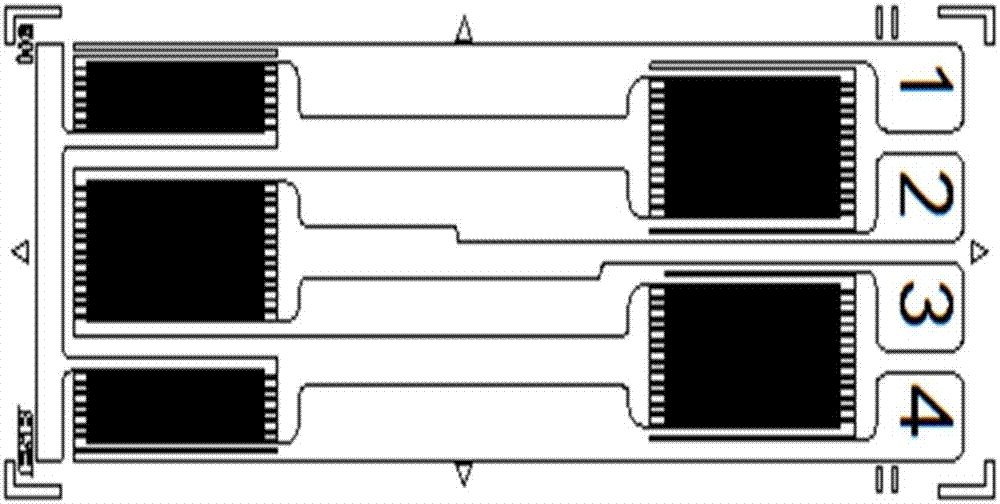

Strain gauge sorter and sorting method

A strain gage and binning technology, applied in the field of strain gage sorting, can solve the problems of difficulty in manual accurate clamping, high mental labor intensity, and wrong bin placement, and achieves a simple structure, reduced mental labor intensity, and convenient implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

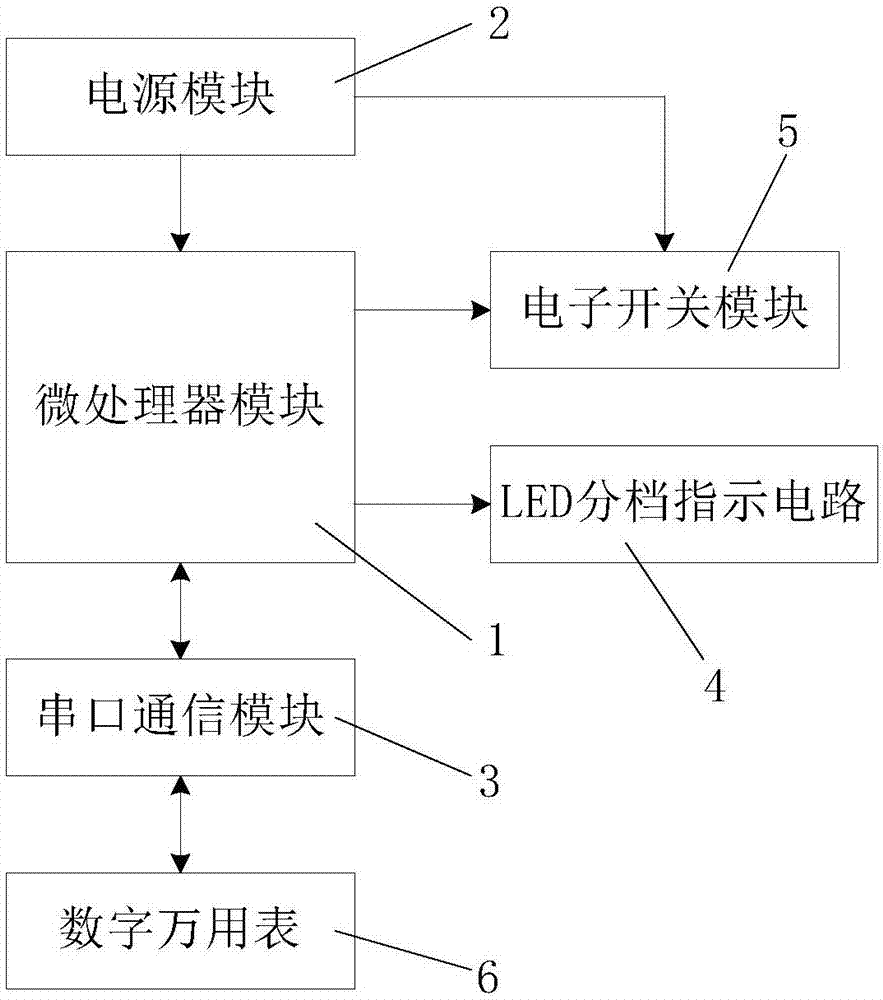

[0050] Such as image 3 As shown, the strain gauge sorting instrument of the present invention includes a microprocessor module 1 and a power supply module 2, and a serial port communication module 3 connected with the microprocessor module 1 and used to connect a digital multimeter 6, the microprocessor module The output terminal of 1 is connected with LED classification indicating circuit 4 and electronic switch module 5, and described microprocessor module 1 and electronic switch module 5 are all connected with the output terminal of power supply module 2, and described electronic switch module 5 and digital multimeter 6 connect.

[0051] In this example, if Figure 5 As shown, the microprocessor module 1 includes a single-chip microcomputer AT89C52, a crystal oscillator circuit and a reset circuit, and the crystal oscillator circuit includes a crystal oscillator X1, a non-polar capacitor C1 and a non-polar capacitor C2, one end of the crystal oscillator X1 and a non-polar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com