Bag type shampoo liquid filling system

A filling system, shampoo technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as opening shampoo, ignorance, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

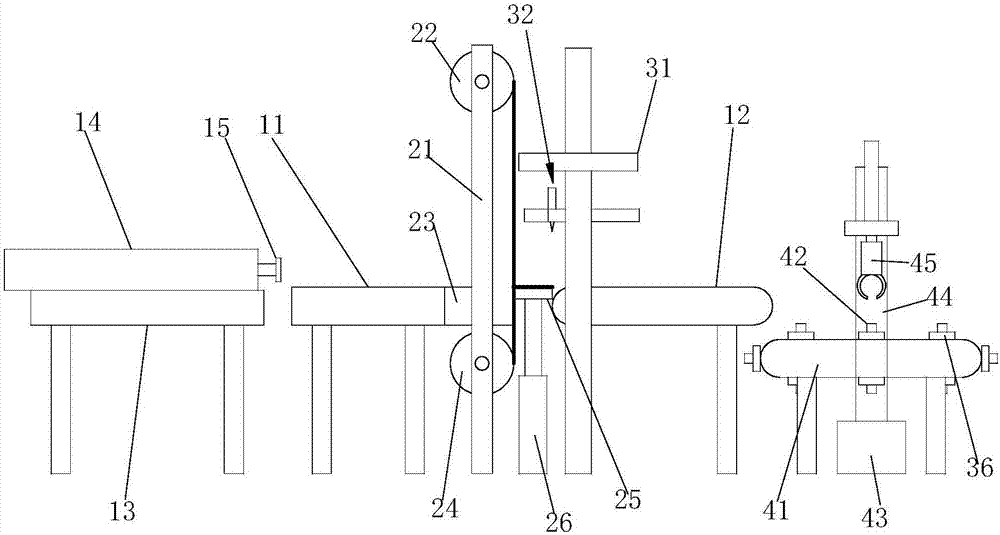

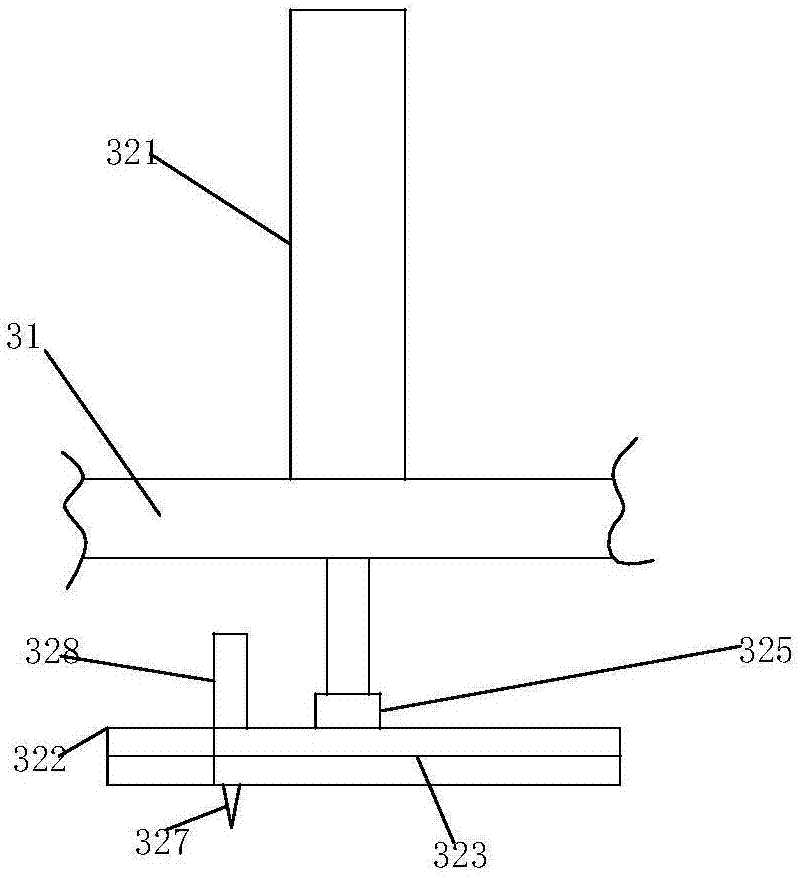

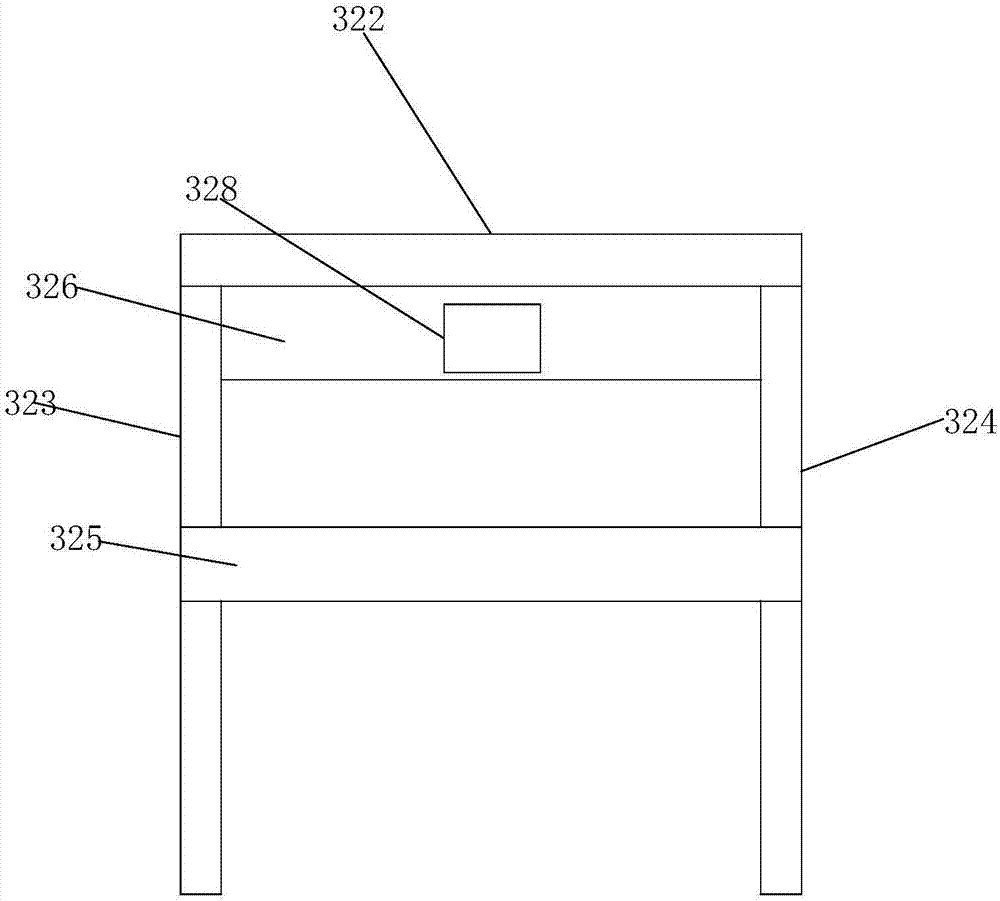

[0020] Such as figure 1As shown, this embodiment proposes a bag-type shampoo filling system, including: unsealed bag preparation equipment, which includes a number of expansion parts (not shown in the figure), each expansion part includes a square barrel-shaped structure The shell, the sealing end of the shell is provided with a permanent magnet, the unsealed end of the shell is provided with a closing block, and the closing block is made of foam material; the first conveyor belt 11 for inputting the expansion part is erected on the ground, and the first conveyor belt 11 A second conveyor belt 12 is erected on one side of the output end, the transmission direction of the second conveyor belt 12 is perpendicular to the transmission direction of the first conveyor belt 11, and a support table 13 is erected on the other side of the output end of the first conveyor belt 11, on which the first conveyor belt 13 is installed. A cylinder 14, the telescopic rod of the first cylinder 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com