Biological fermenting device with multiple stirring shafts

A biological fermentation and multi-stirring technology, applied in the field of fermentation, can solve the problems of uneven stirring of fermentation raw materials, affecting the normal progress of fermentation, and insufficient contact of raw materials, etc., to achieve the effect of increasing the stirring range, reducing the dead angle of stirring, and fully stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

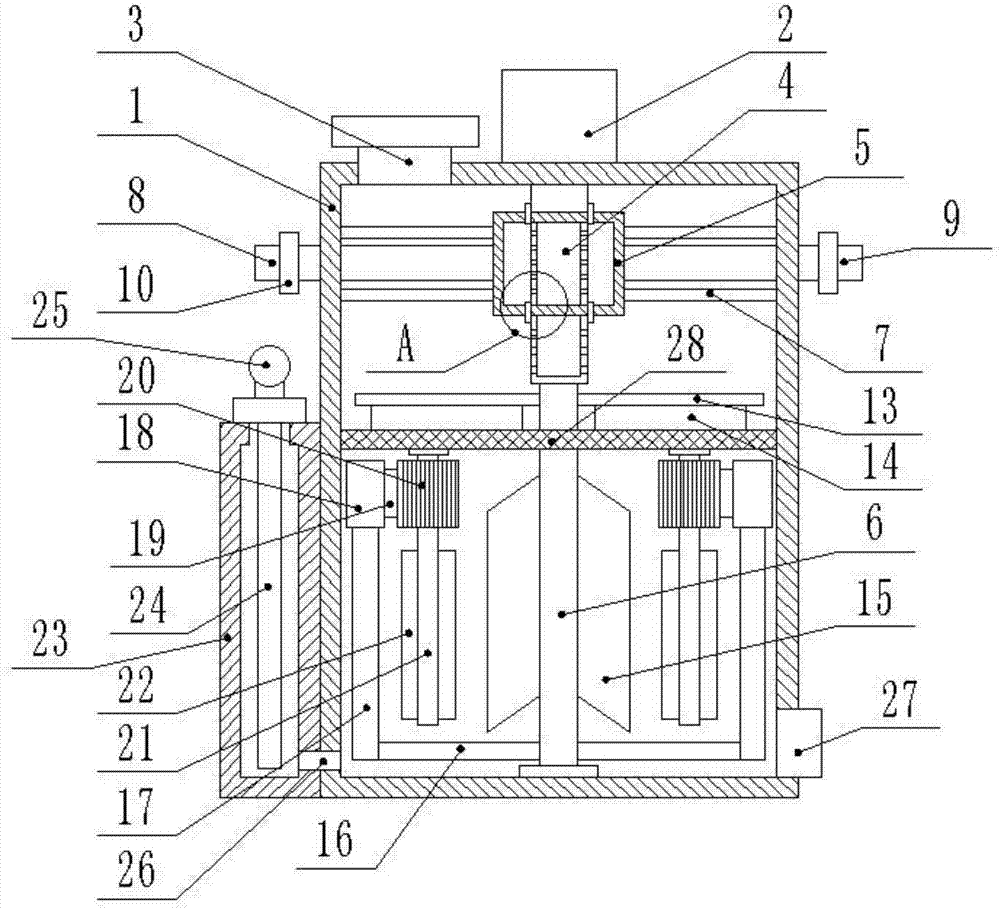

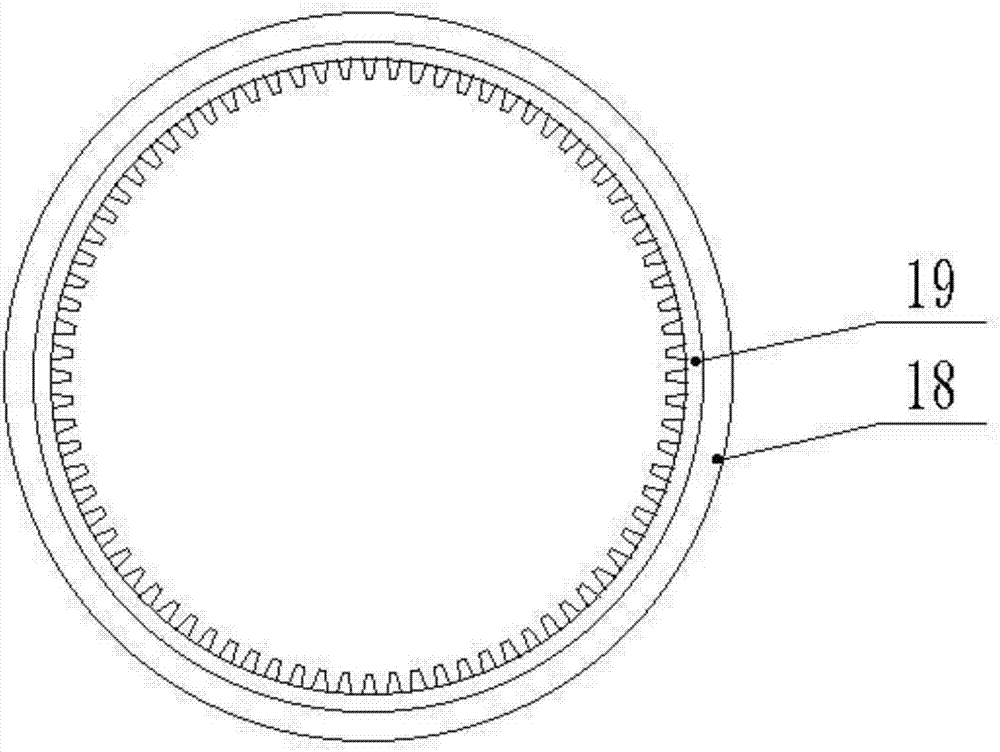

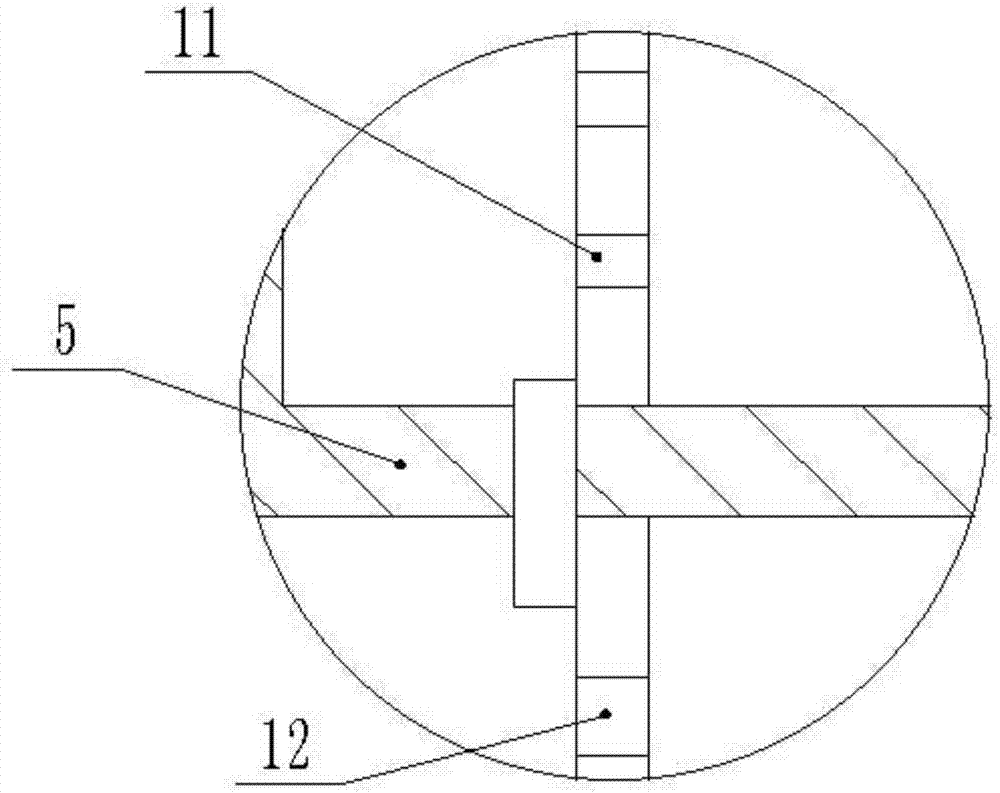

[0018] Please refer to the figure, in the embodiment of the present invention, a bio-fermentation device with multiple stirring shafts includes a housing 1, a motor 2, a feed port 3 and a sampling chamber 23; the motor 2 is fixedly installed on the top of the housing 1, The output shaft of the motor 2 extends vertically downwards into the housing 1, and a vertical dispersing pipe 4 is fixedly connected to the lower end of the output shaft of the motor 2, and a sealing box 5 is set on the outer side of the dispersing pipe 4, and the dispersing pipe 4 and the The sealing box 5 is rotationally connected, the sealing box 5 is fixed in the housing 1 through the support rod 7, the dispersing pipe 4 rotates on the sealing box 5, and several dispersing inlet holes are opened on the side wall of the corresponding dispersing pipe 4 in the sealing box 5 11, and evenly distributed, on the side wall of the dispersing pipe 4 corresponding to the outside of the sealed box 5, there are several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com