Vehicle parking platform device

A platform device and vehicle technology, which is applied in the field of vehicle parking platform devices and vehicle parking platforms, can solve the problems of short parking time, small contact area, pollution and corrosion of the body surface quality, and achieve the effect of avoiding damage and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

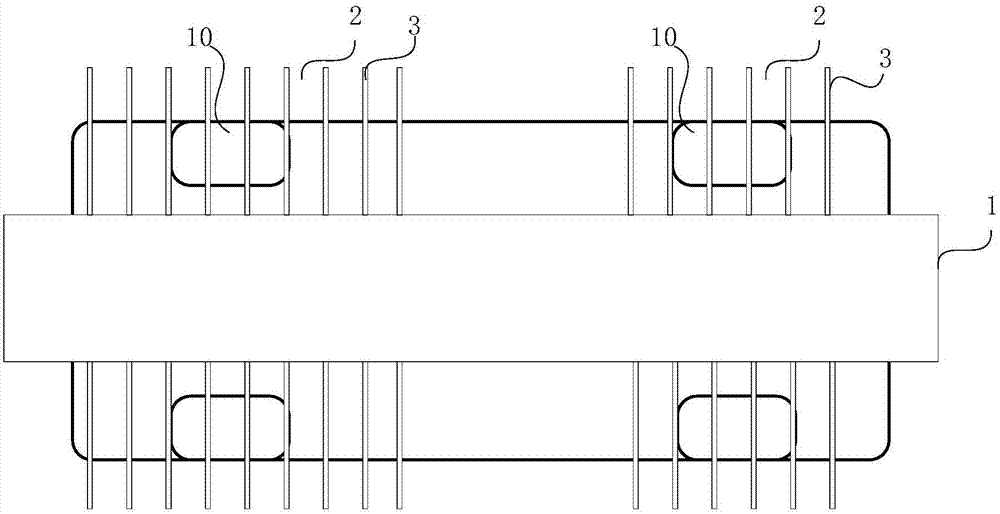

[0048] see Figure 1 to Figure 3 , the present invention discloses a vehicle parking platform device, which is an improved comb-shaped parking platform, and the vehicle parking platform device includes: a parking platform 1, several tire positions 2 located on the parking platform; the tire positions 2 There are several supporting mechanisms 3;

[0049] Several elastic mechanisms 4 are arranged above the support mechanism 3, so that when the tire 10 is placed on the support mechanism 3, each elastic mechanism 4 elastically deforms downward, so that a plurality of elastic mechanisms 4 contact the tire 10. The tire 10 provides support.

[0050] In this embodiment, each supporting mechanism 3 is arranged in a horizontal direction, forming a comb shape; above the supporting mechanism 3, several elastic mechanisms 4 arranged vertically are arranged.

[0051] The surface of each supporting mechanism 3 is coated with a flexible material as a protective layer. The radial section of...

Embodiment 2

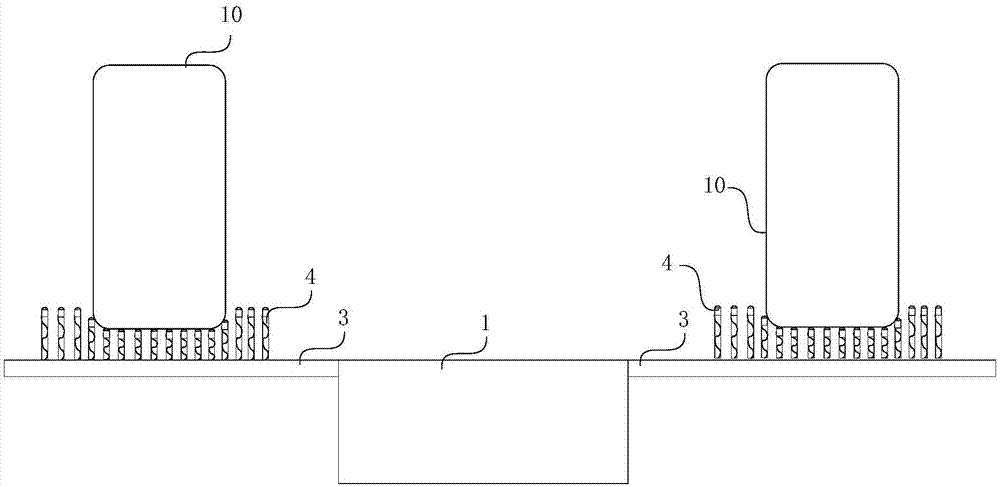

[0053] see figure 1 , Figure 4 , Figure 5 The difference between this embodiment and Embodiment 1 is that, in this embodiment, at least one elastic mechanism 4 arranged longitudinally is provided between the support mechanism 3 and the parking platform 1 .

[0054]At least one longitudinally arranged elastic mechanism 4 is provided between the support mechanism 3 and the parking platform 1; so that when the tire 10 is placed in the tire position 2, several support mechanisms 3 in each support mechanism 3 are subjected to the lowering of the vehicle. Under the pressure, the downward displacement occurs under the action of the corresponding elastic mechanism 4 , so that more support mechanisms 3 are in contact with the tire 10 to provide support for the tire 10 .

Embodiment 3

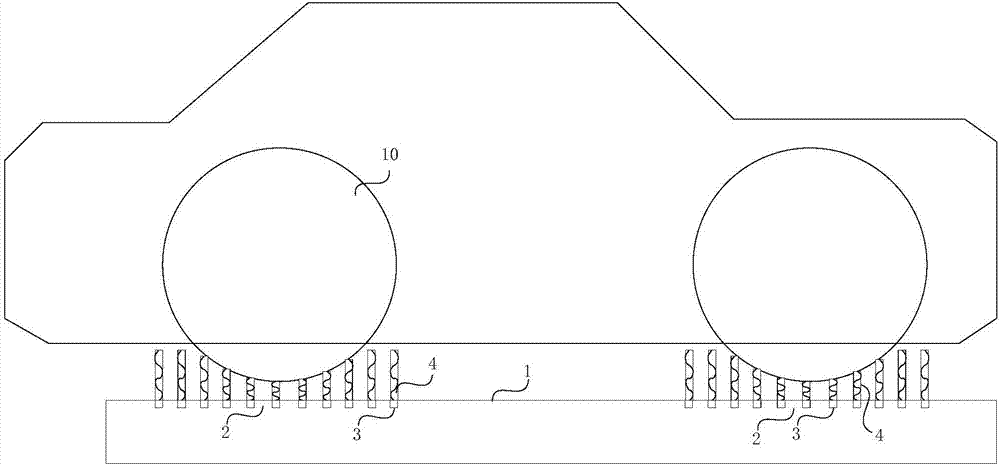

[0056] see Figure 6 to Figure 8 , The difference between this embodiment and Embodiment 1 is that in this embodiment, each supporting mechanism 3 is arranged vertically.

[0057] Specifically, the tire position 2 is provided with a number of longitudinally arranged support mechanisms 3, and a longitudinally arranged elastic mechanism 4 is arranged between the support mechanism 3 and the parking platform 1; or, the support mechanism 3 includes an elastic mechanism 4, and the support mechanism 3 even Can be elastic mechanism.

[0058] When the tire 10 of the vehicle is placed in the tire position 2 , the elastic mechanisms 4 of some of the support mechanisms 3 in each support mechanism 3 contract downwards, so that the tire 10 is in contact with the plurality of support mechanisms 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com