Three-dimensional metal energy dissipation damper

A damper, three-dimensional technology, applied in the direction of building components, building types, earthquake resistance, etc., can solve the problems of three-dimensional vibration damper bulky, lack of practical engineering application, difficult to promote and use, etc., to achieve strong designability and simple structure , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

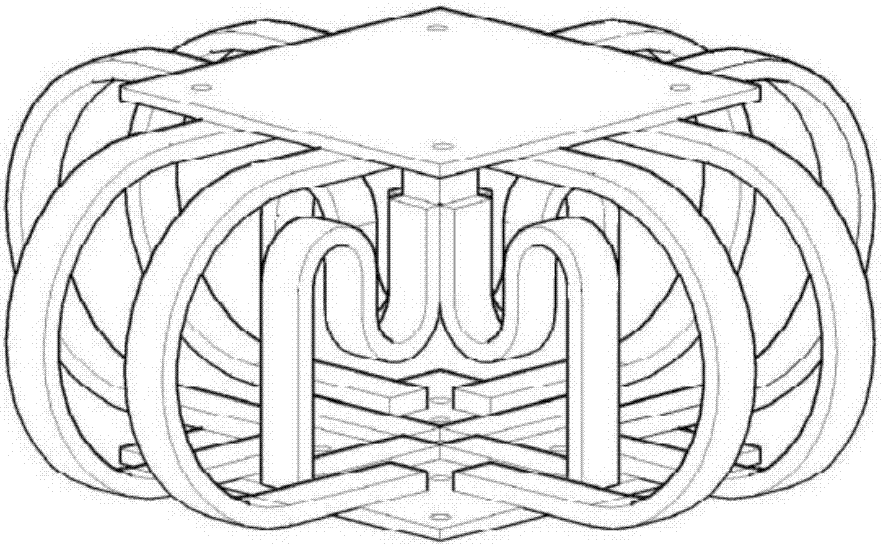

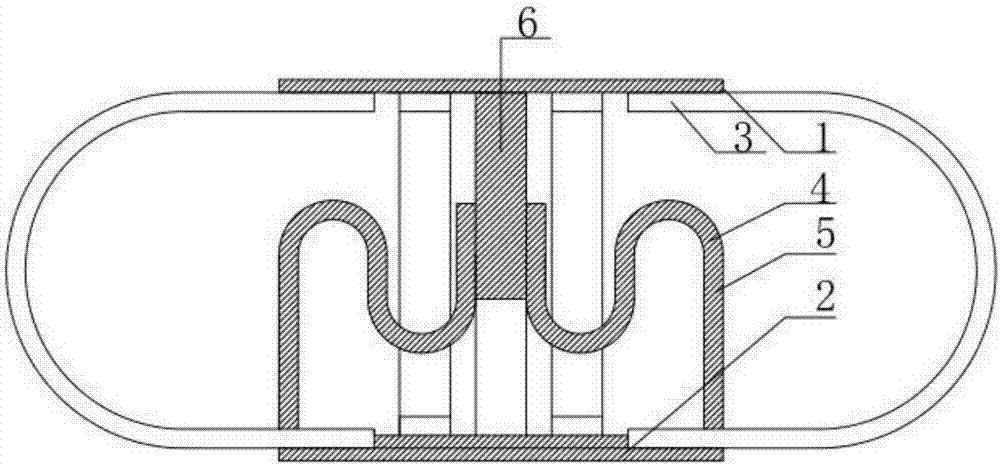

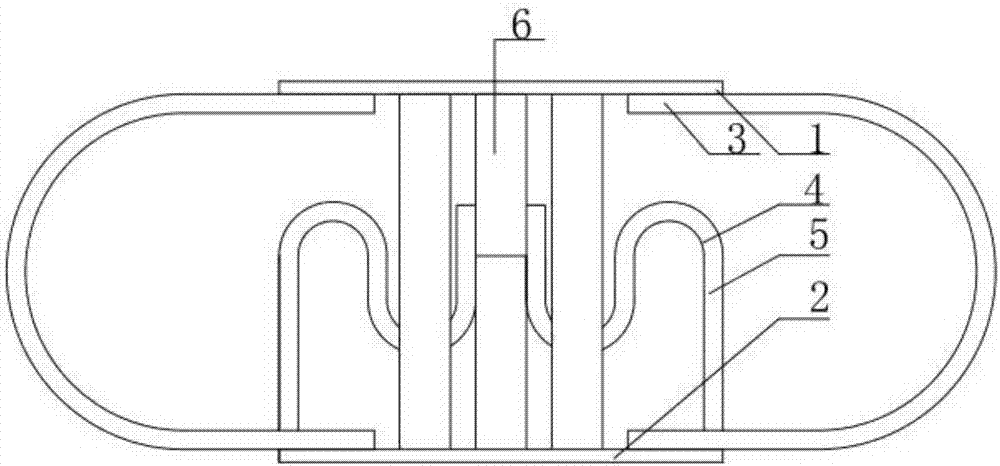

[0038] Such as figure 1 , 3 As shown, a three-dimensional metal energy dissipation damper includes an upper connecting plate 1 , a lower connecting plate 2 , U-shaped steel 3 and S-shaped steel 4 , lateral connecting support columns 5 and central rectangular connecting columns 6 . figure 2 As shown in the sectional view, the energy-dissipating elements mainly include the outer U-shaped steel 3 and the inner S-shaped steel 4. The two straight sections of the U-shaped steel 3 are firmly connected with the upper connecting plate 1 and the lower connecting plate 2 respectively to form a whole. The connection method here can be bolted. Connection or welding, the connection method in this example is welding; the outer surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com