Electric-propulsion-field microthrust transient measurement system based on dynamic photoelastic method

A dynamic photoelasticity, measuring system technology, applied in force/torque/work measuring instruments, measuring force, measuring devices, etc., can solve the electromagnetic interference of thrusters, difficult to measure transient thrust, and unable to measure the magnitude of transient thrust of thrusters value and other problems to achieve the effect of reducing mechanical vibration and solving zero drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

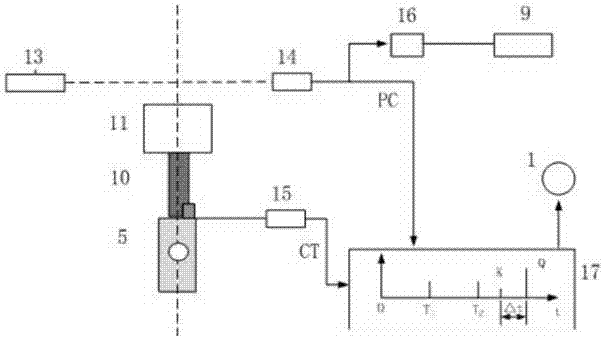

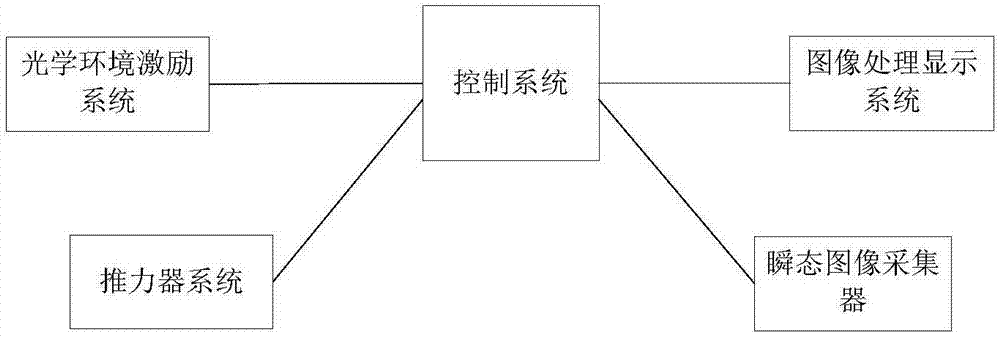

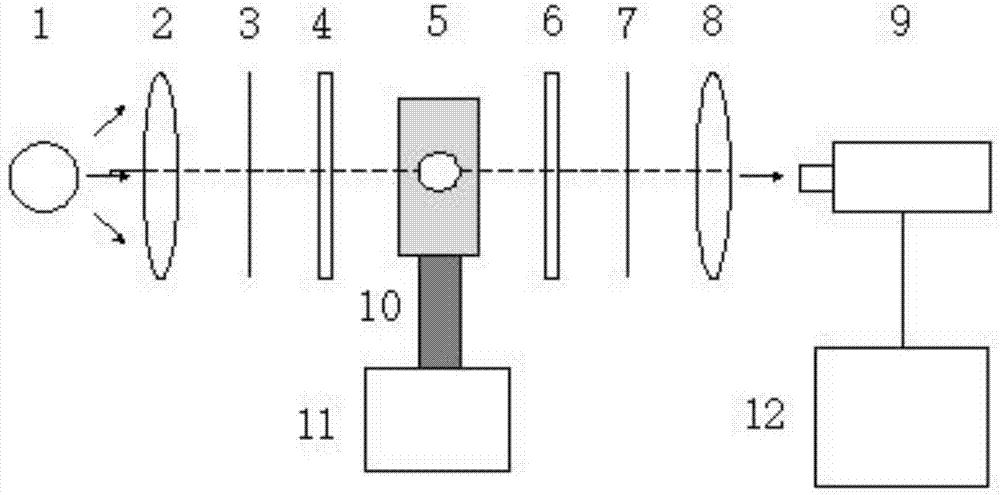

[0035] According to the thrust characteristics of electric propulsion, the present invention is based on the dynamic photoelasticity method and constructs an optical path system with optical elastic elements as the core, and displays the magnitude and change of the instantaneous force by measuring the real-time change of the optical fringe image when it is stressed. The system includes a laser, an optical elastic element, a high-speed transient image collector and necessary image processing techniques. The invention is mainly used for collecting the transient thrust constantly changing with time generated by the pulse type propulsion system. Based on the stress-optical law, the system uses photoelastic special materials and high-speed photography devices to visualize the thrust generated by the thruster, especially to record the change process of the thrust, which is convenient for studying the change mechanism of the thrust of the electric propulsion thruster.

[0036] This s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com