OLED screen pneumatic pressing needle device

A lifting device and screen technology, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problem of not lighting up, not enough brightness, etc., to achieve the effect of sufficient brightness, consistent trajectory, and avoiding not lighting up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

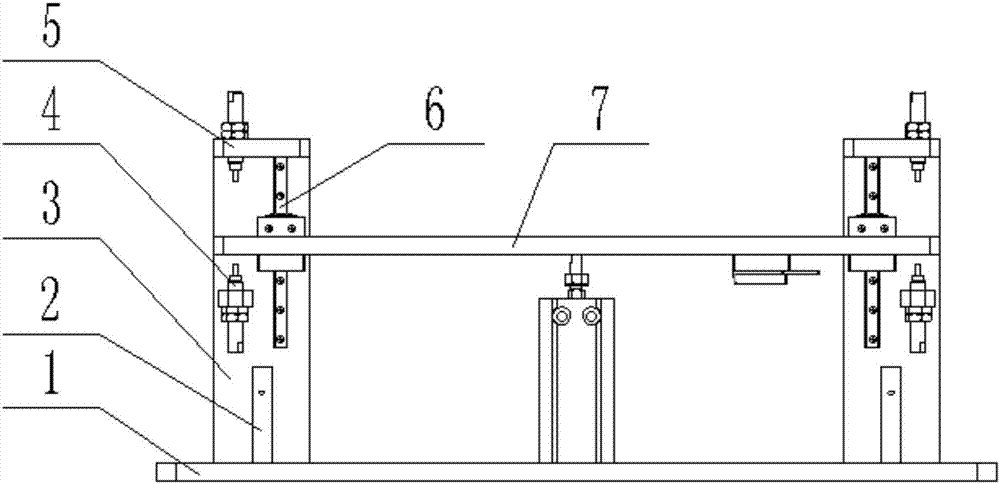

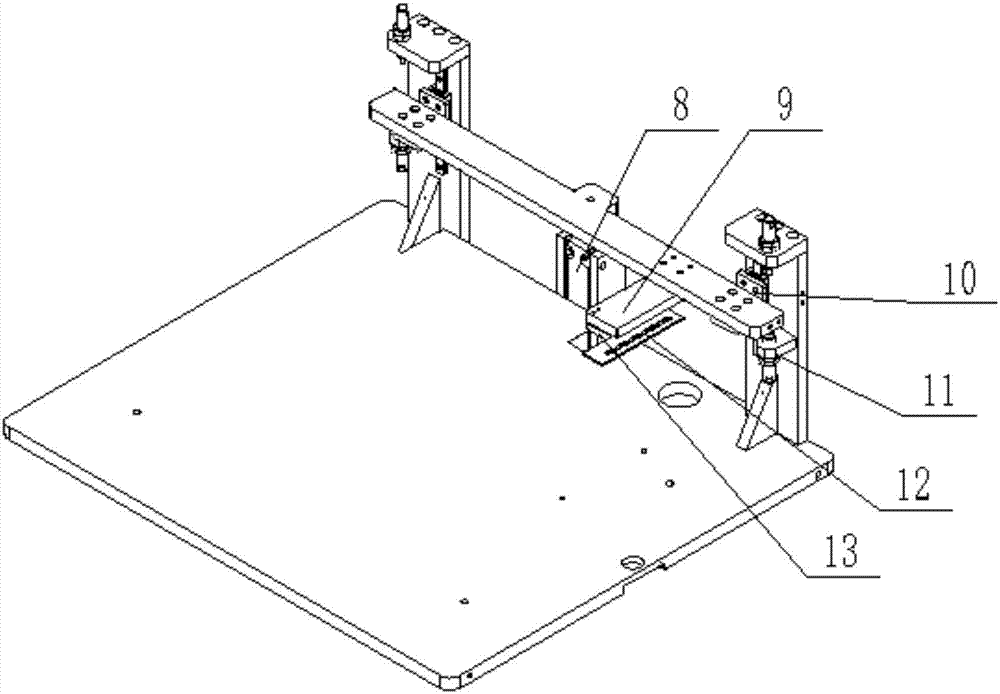

[0026] like figure 1 , 2 As shown, a pneumatic needle pressing device for an OLED screen includes a horizontally arranged loading bottom plate 1, a vertically arranged guide rail mounting plate 3 and a horizontally arranged lifting horizontal plate 7, and the guide rail mounting plate 3 is fixedly connected to the loading plate. One side of the object bottom plate 1, the lifting horizontal plate 7 is slidably connected with the guide rail mounting plate 3, and the lifting device for lifting the lifting horizontal plate 7 is provided on the described object loading base plate 1, and on the guide rail mounting plate 3 A buffer device is provided; the lifting horizontal plate 7 is provided with a needle pressing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com