Holographic anti-blue-ray thin film and making method thereof

A production method and anti-blue light technology, applied in optics, optical components, instruments, etc., can solve problems such as complicated production process technology operation, secondary damage to eyes, color distortion of objects, etc., achieve strong refraction ability, avoid secondary damage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

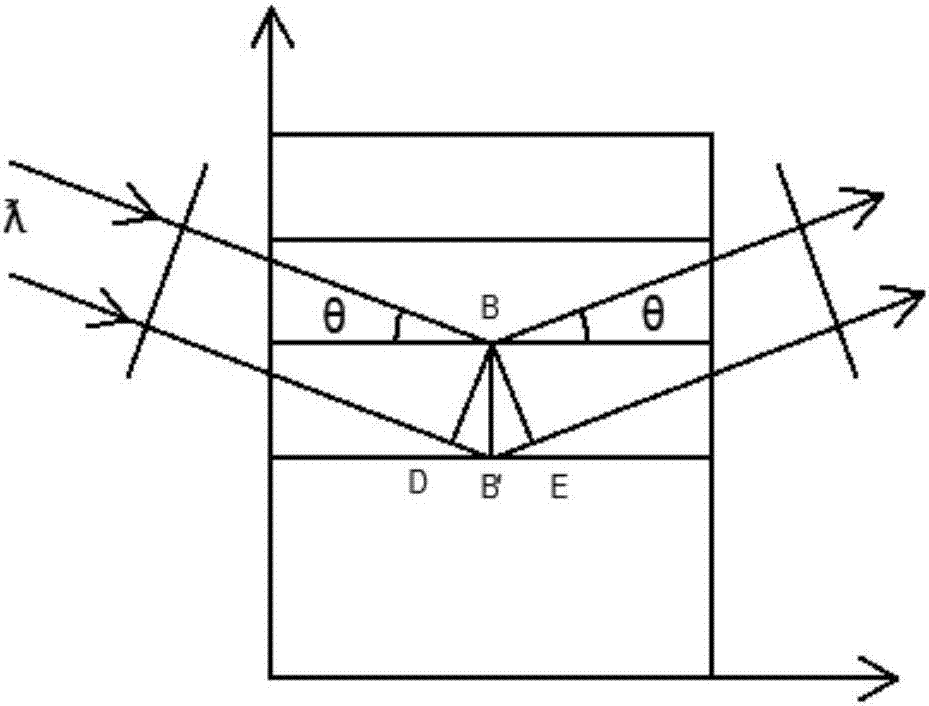

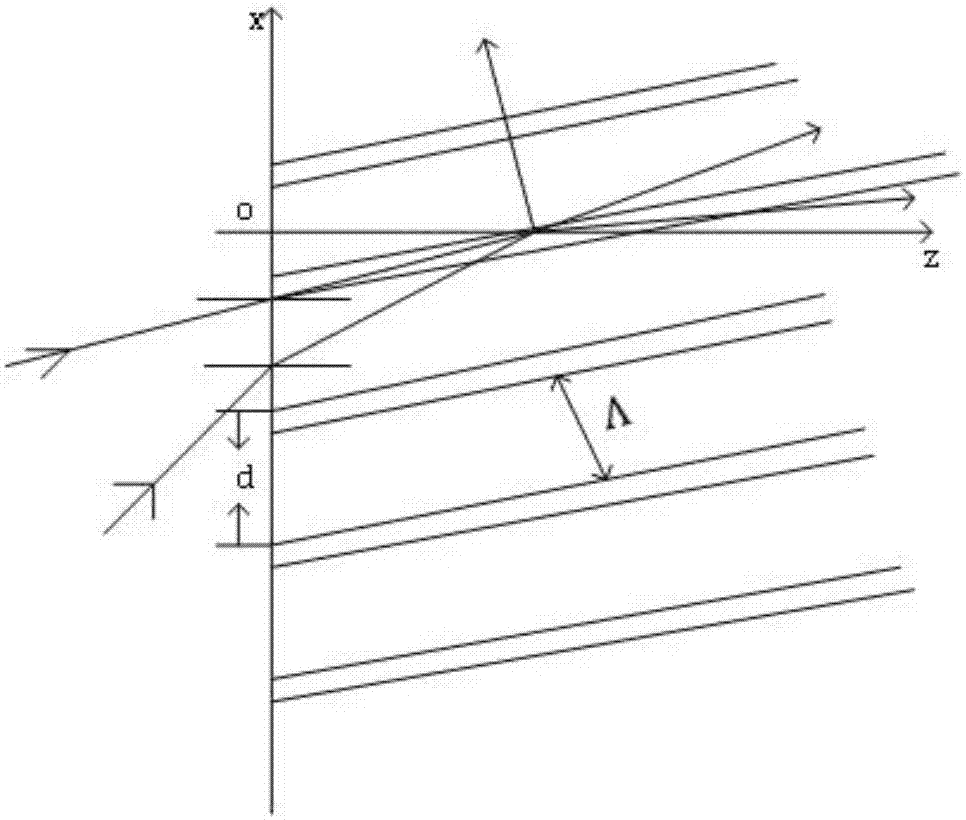

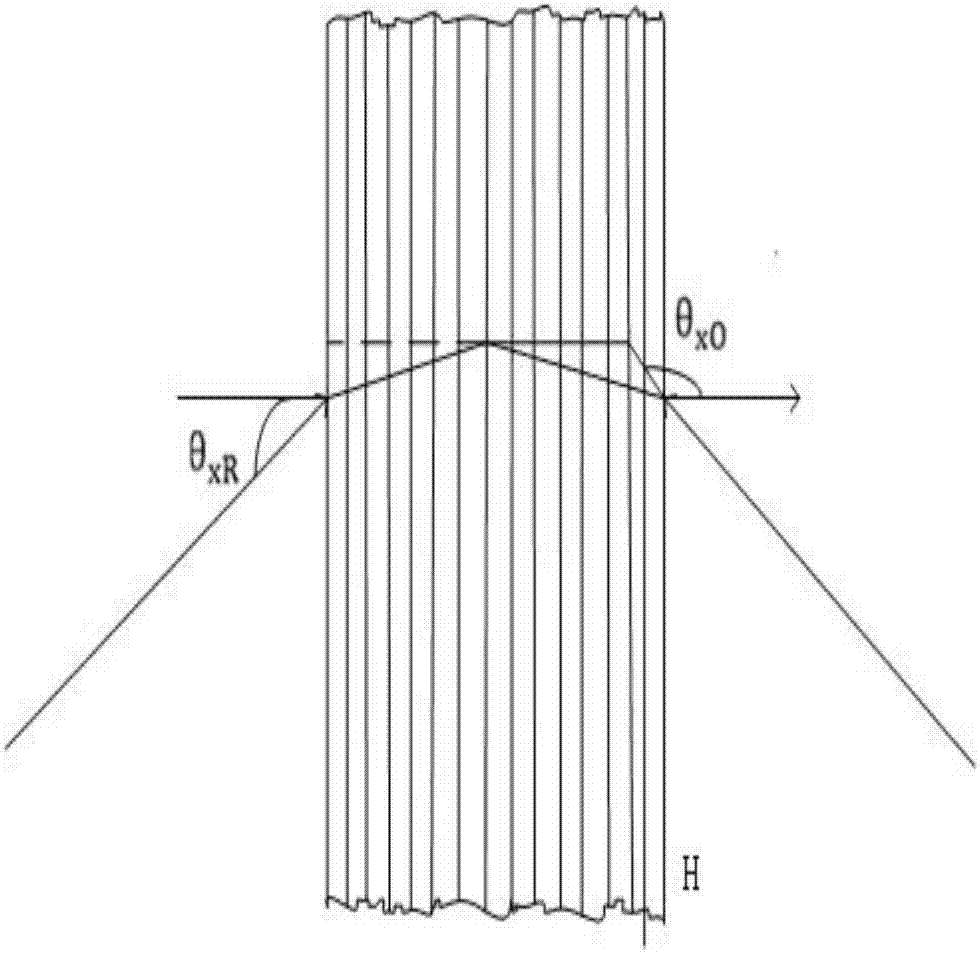

[0033] A method of manufacturing a holographic anti-blue light film as shown in the figure, comprising the following steps:

[0034] S10. Selecting a photoresponsive recording medium and a recording light source to make a volume hologram;

[0035] In the harmful blue light band 400-455nm, blue light with a wavelength of 442-455nm is more harmful to human eyes, so a helium-cadmium laser with a wavelength of 442nm is selected as the recording light source. To avoid factors affecting the production of holograms, dichromate gelatin (DCG), which is more sensitive to visible light, is used as the recording medium to make holographic filters for light waves of a specific b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com