Optimization method for hole drilling simulation of electrophoresis

An optimization method, electrophoresis technology, applied in the direction of electrical digital data processing, CAD circuit design, special data processing applications, etc., can solve problems such as unrealizable, different structure flatness, difficulties, etc., to improve production efficiency, shorten development cycle, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

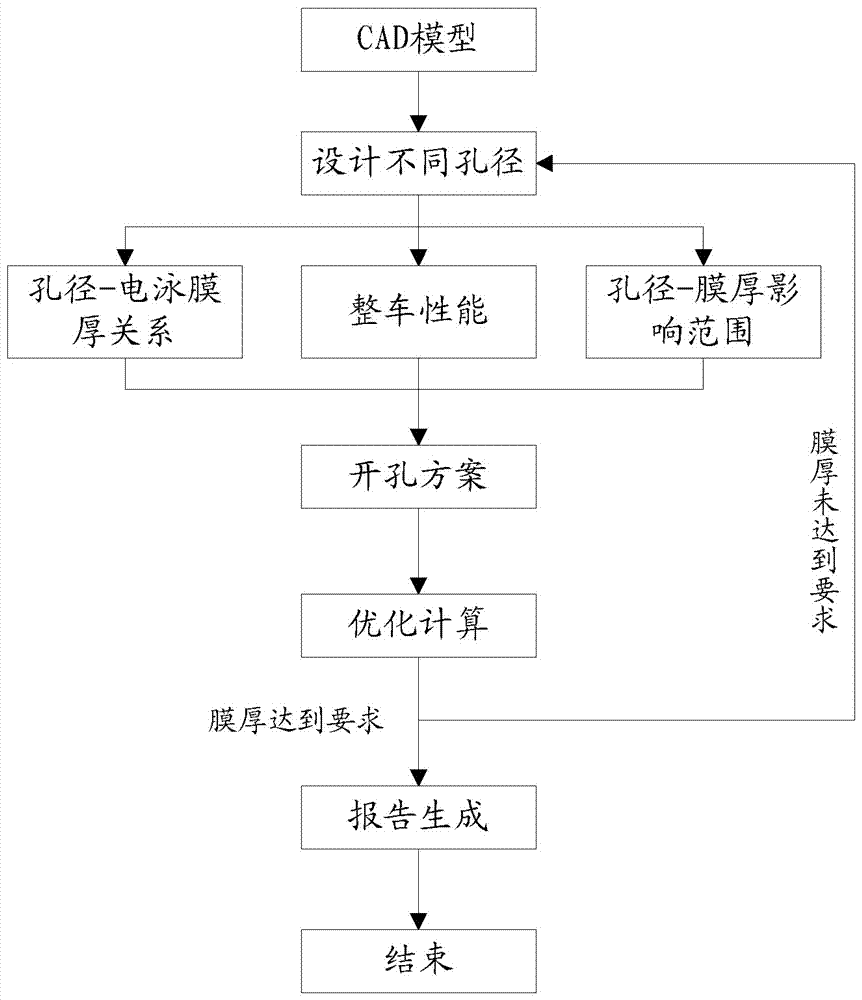

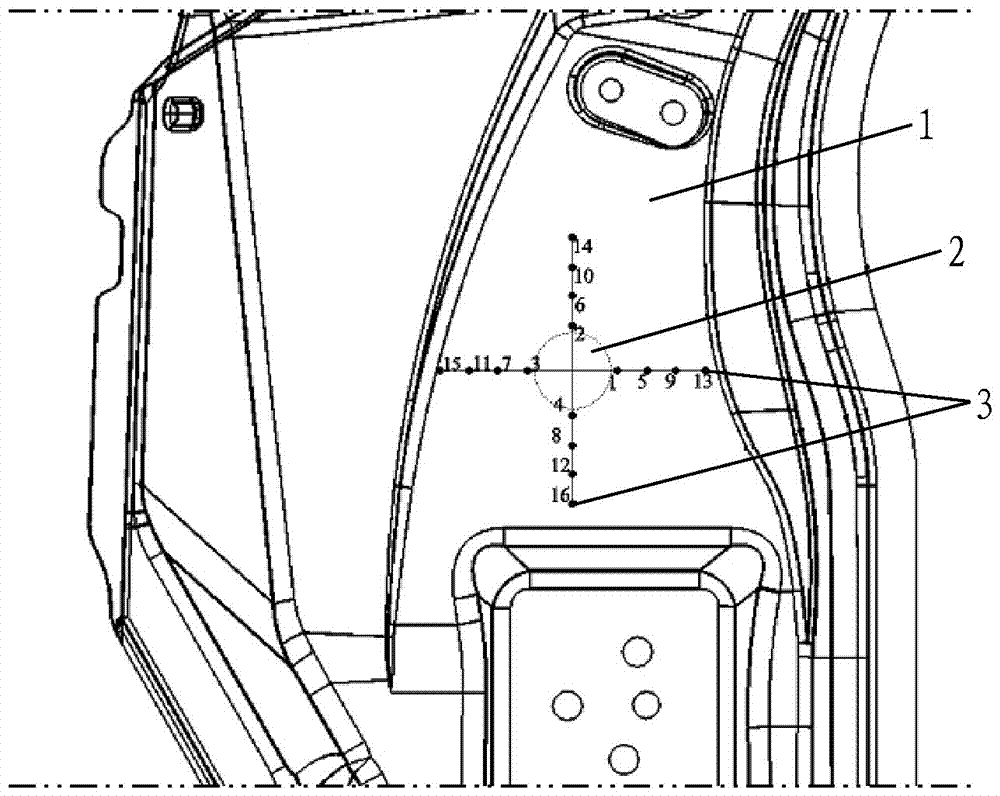

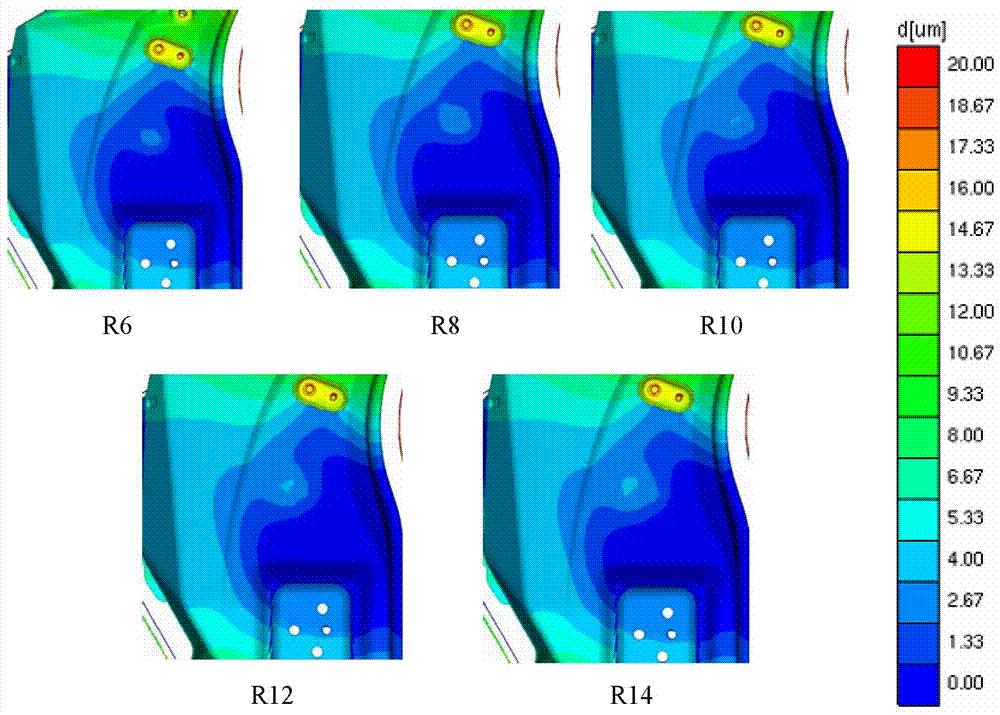

[0031] Please refer to Figure 1 to Figure 8 As shown, a preferred embodiment of an electrophoretic simulation opening optimization method of the present invention, the method includes:

[0032] Step 1. According to the poor electrophoretic area of the vehicle coating film, find the corresponding area position in the modeling model, that is, find the corresponding position in the modeling model according to the poor electrophoretic area of the vehicle for simulation calculation, And design holes with different pore diameters in the corresponding area positions and perform electrophoresis simulation calculations to obtain the relationship between the pore diameter and the thickness of the electrophoretic film; the so-called poor electrophoresis area refers to the area where the film thickness of the vehicle coating film does not meet the requirements. , the film thickness can be detected by a film thickness meter. In the specific production process, due to the consideration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com