Power battery dismounting device and power battery recycling system

A power battery and sorting device technology, which is applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of low efficiency and potential safety hazards in manual dismantling of power batteries, so as to prevent harm to human health and improve dismantling efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

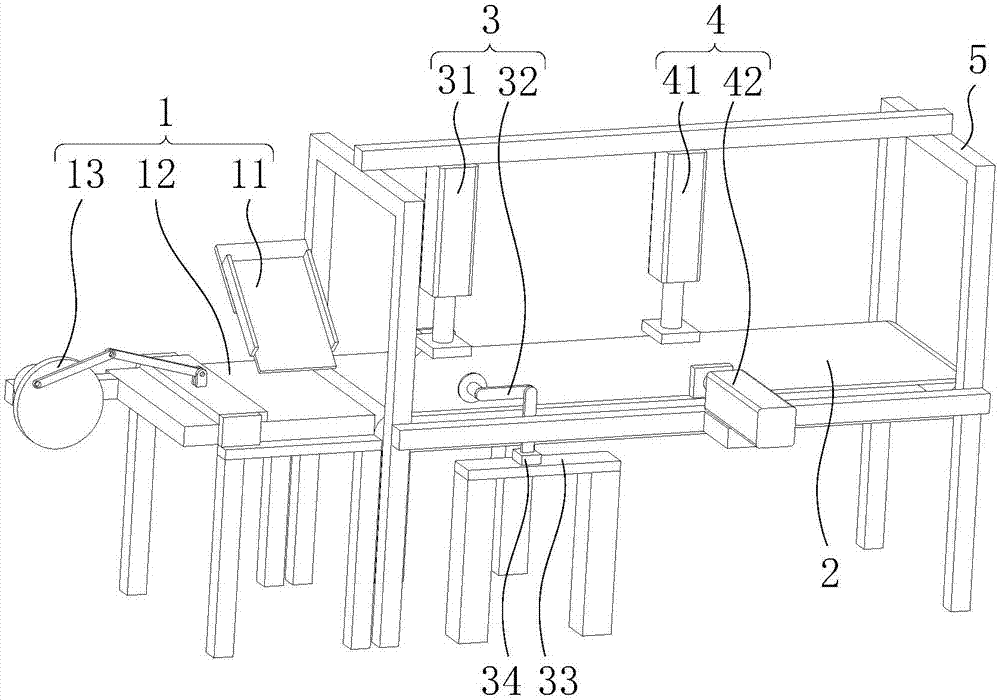

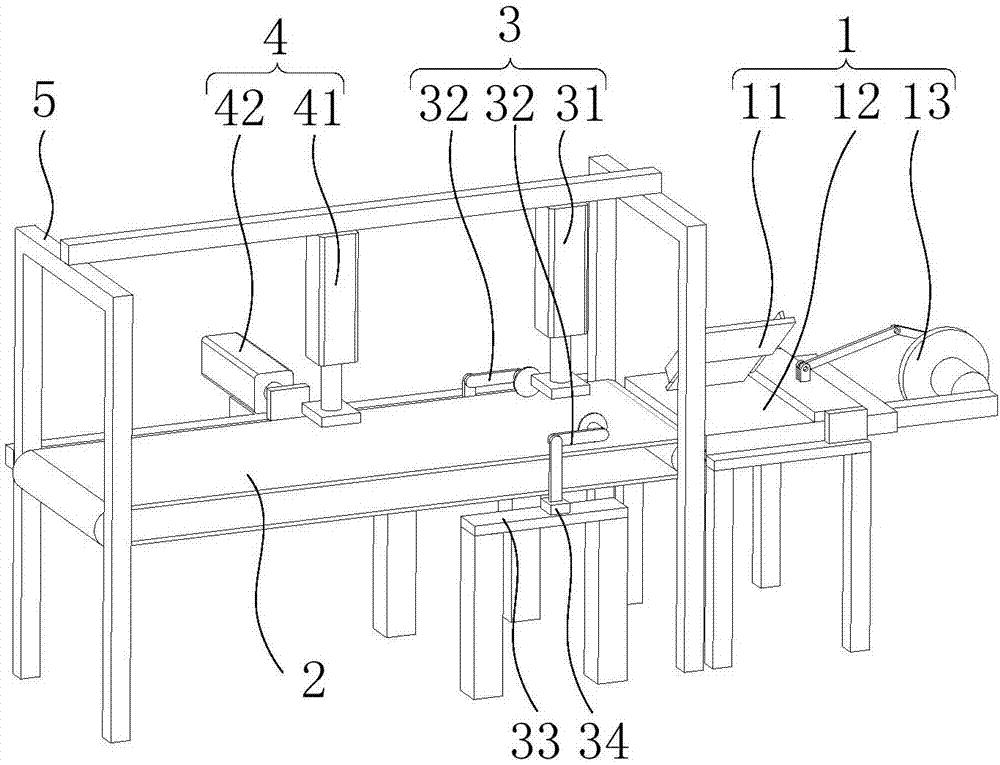

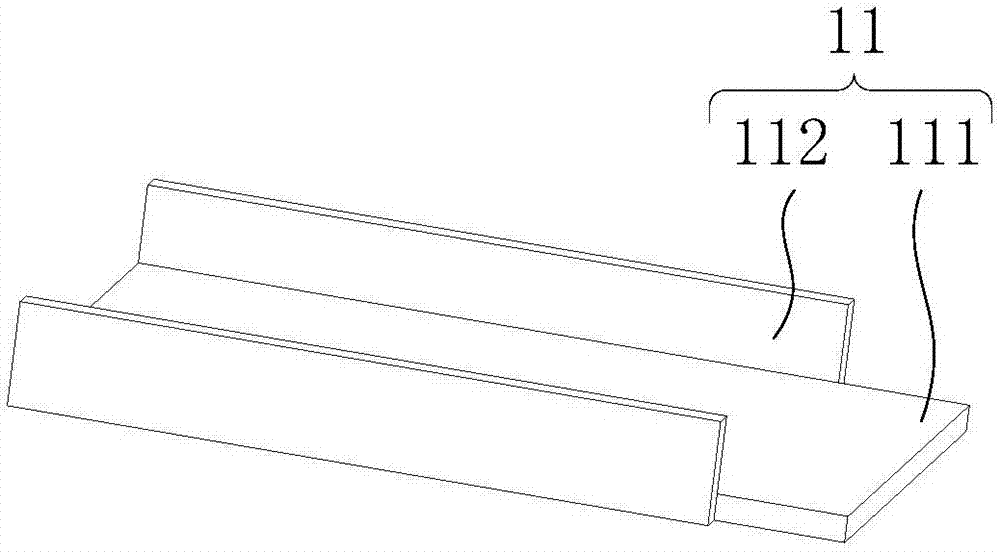

[0031] figure 1 Schematic diagram of the structure of a power battery disassembly device provided by an embodiment of the present invention Figure one , figure 2 Schematic diagram of the structure of a power battery disassembly device provided by an embodiment of the present invention Figure II . Such as figure 1 with figure 2 As shown, the power battery disassembling device provided by the embodiment of the present invention includes: a feeding mechanism 1, a feeding mechanism 2, a cutting mechanism 3 for cutting opposite ends of the power battery, and a cutting mechanism 3 for pushing the battery cell out of the battery shell. The core pushing mechanism 4; the feeding mechanism 1 is connected with the feeding mechanism 2, the cutting mechanism 3 and the core pushing mechanism 4 are arranged along the conveying direction of the feeding mechanism 2, and the feeding mechanism 2 transports the power battery through the cutting mechanism 3 and the core pushing mechanism in turn ...

Embodiment 2

[0055] The purpose of the second embodiment is to provide a power battery recovery system to alleviate the technical problems in the prior art that the manual disassembly of the power battery has low efficiency and potential safety hazards.

[0056] The power battery recovery system provided by the second embodiment includes: a battery cell disassembly device, a crushing device, a sorting device, a metal extraction device, and the power battery disassembly device provided in the first embodiment. Among the battery cell disassembly device and the power battery disassembly device The battery cell conveying mechanism is connected, the crushing device is connected with the decomposition device and the sorting device, and the metal extraction device is connected with the sorting device.

[0057] The battery disassembly device disassembles and separates the battery case and the battery cell. The battery cell is transported to the cell disassembly device. The battery disassembly device bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com