Shockproof pouring-type fire-proof bus duct

A technology of fire-resistant busway and fireproof board, which is applied in the field of busway, which can solve the problems of rough workmanship, easy damage of fireproof board, and fire resistance that cannot meet fire protection requirements, so as to prevent damage and ensure fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

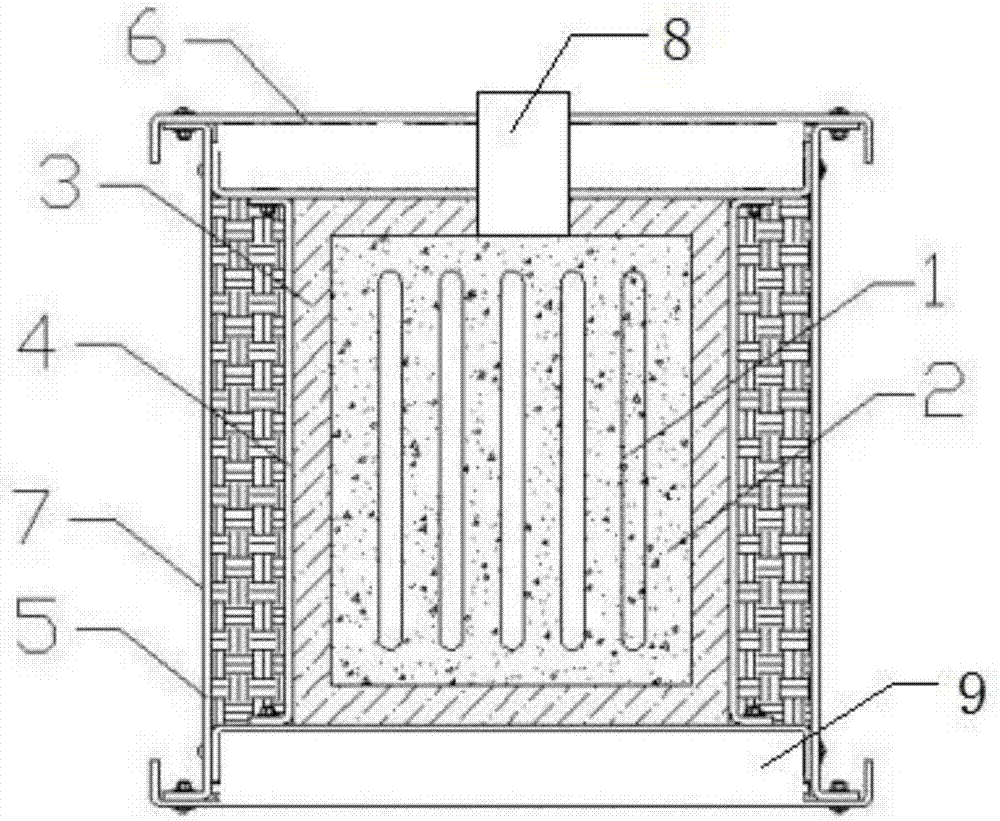

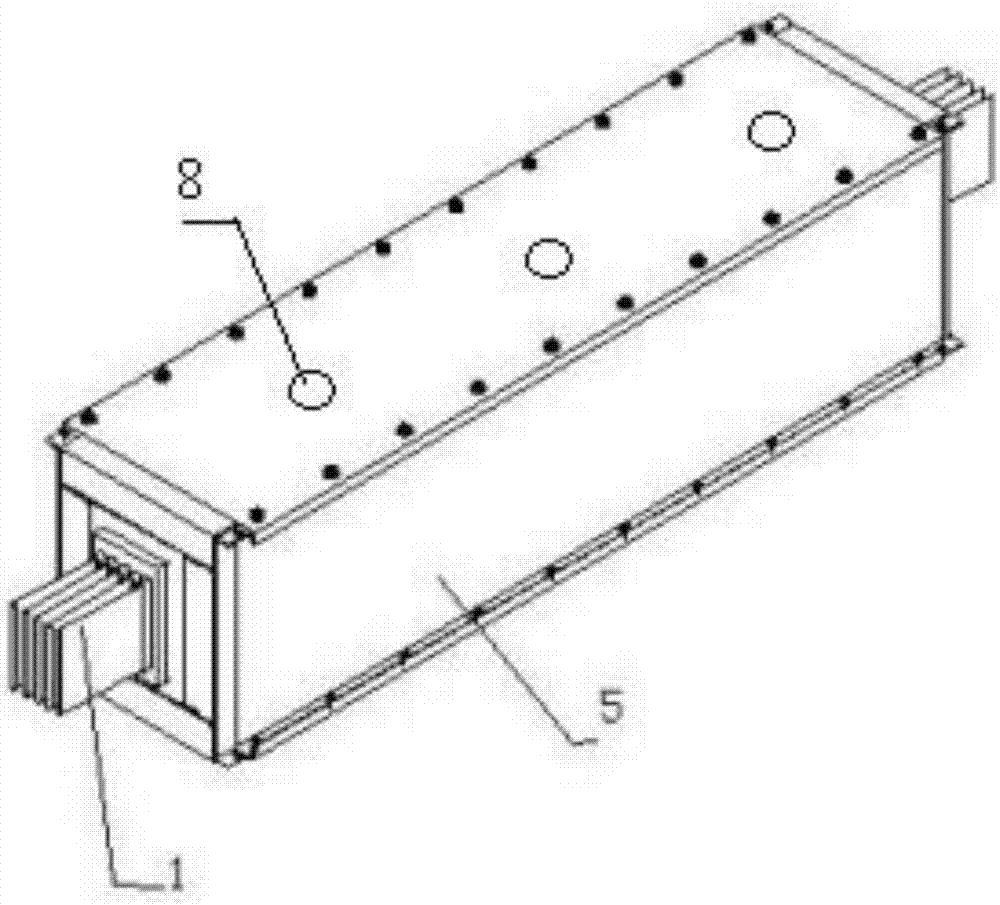

[0014] The following describes in detail an earthquake-proof cast-type refractory bus duct of the present invention with reference to the accompanying drawings.

[0015] Such as figure 1 with figure 2 As shown, a shock-proof cast-type fire-resistant bus duct includes a number of cable troughs for placing cables 1, an insulating waterproof body for placing the cable trough 1, a fireproof board 3 arranged outside the insulating waterproof body 2, and a fireproof board 3 through The inner shell 4 is tightly attached to the insulating and waterproof body 2, the outer shell 5 is fixed on the outside of the inner shell 4 by screws, the gap between the inner shell 4 and the outer shell 5 is filled with fillers, and the top of the busway is equally spaced There are several fireproof liquid tanks 8 for placing fireproof liquid; the bottom of the fireproof liquid tank 8 is made of wax blocks with a low melting point; the wax blocks have a melting point of 80 degrees Celsius; the fillings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com