An all-aluminum engine cylinder inner wall ceramic fixture

An engine block, ceramic technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve problems such as difficulty in finding positioning points, production methods cannot meet requirements, complex design, etc., to solve the accumulation of bubbles and agglomeration problems, avoid erosion, reduce fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

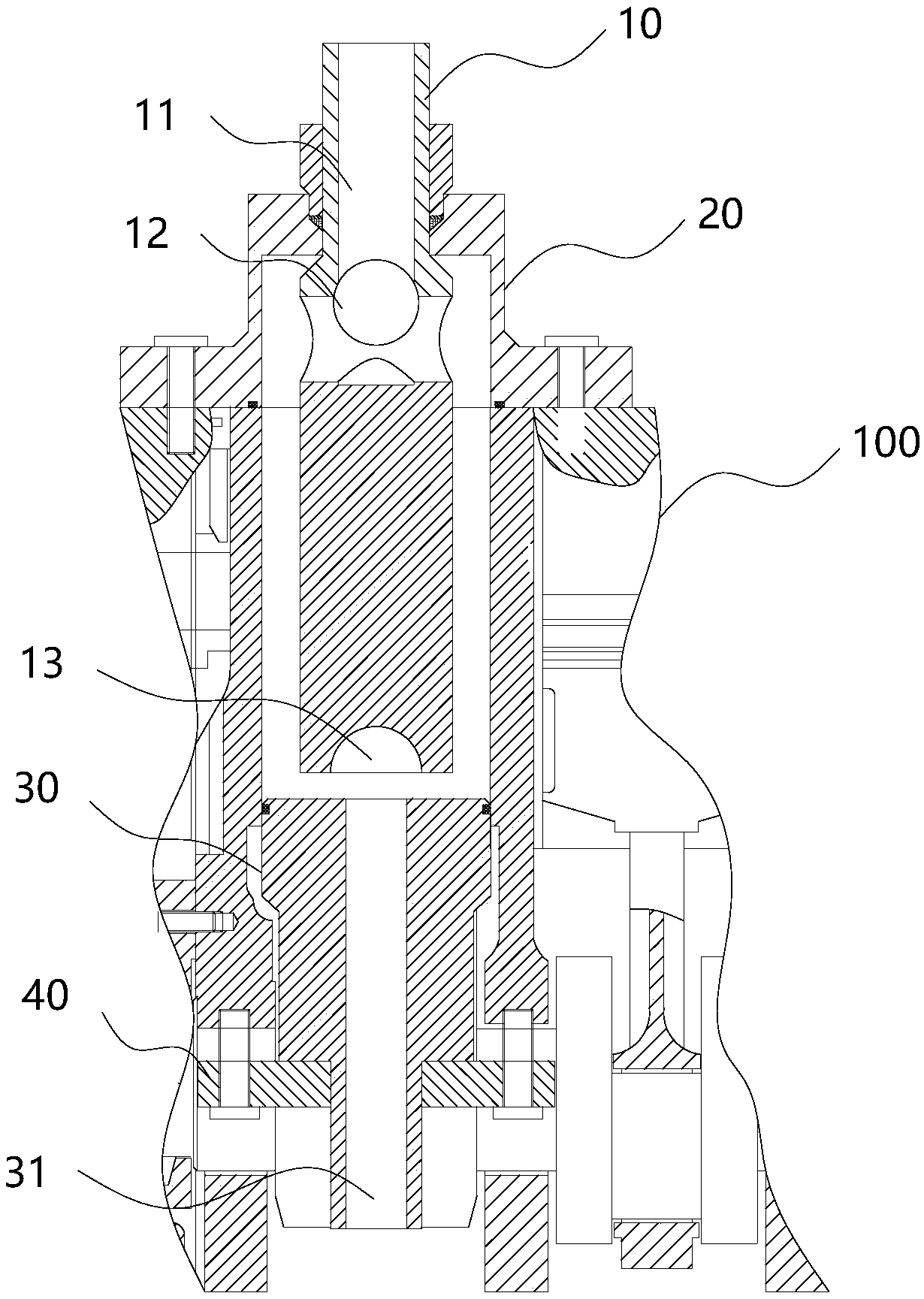

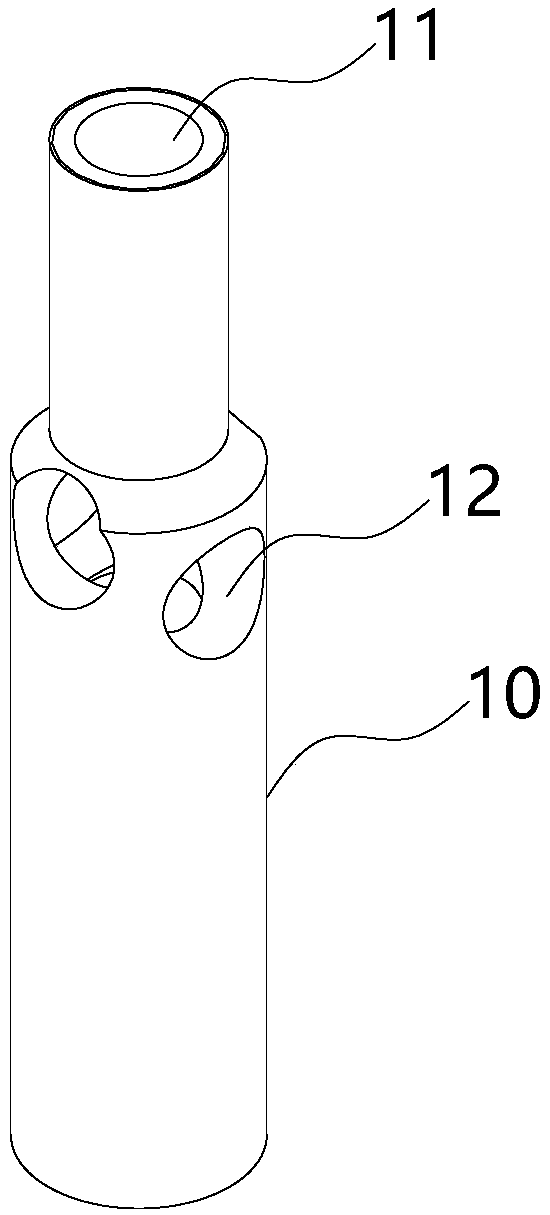

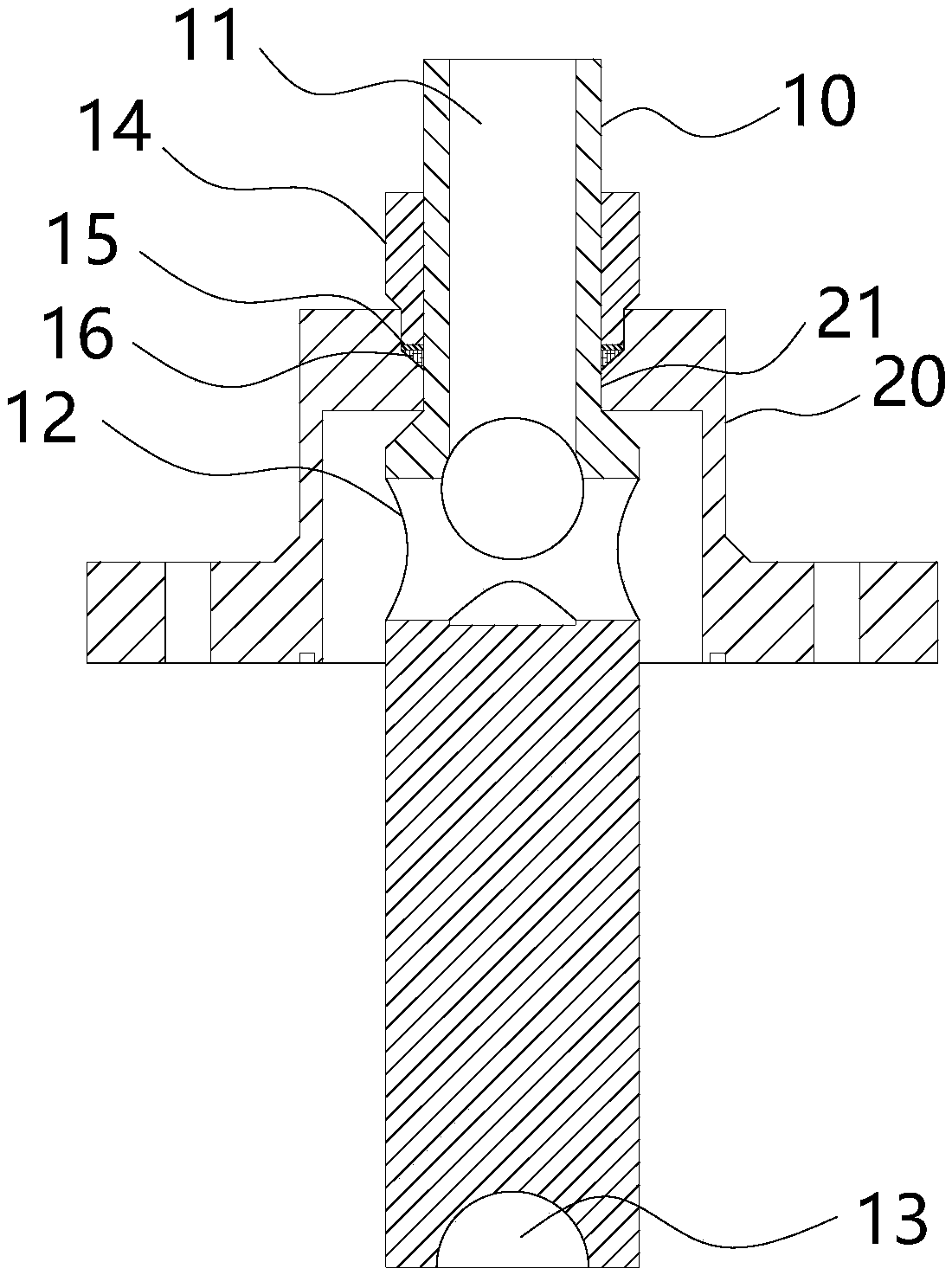

[0022] Such as figure 1 As shown, the all-aluminum engine cylinder inner wall ceramization fixture according to an embodiment of the present invention generally includes a reaction part and a liquid inlet part.

[0023] The reaction part is used to form a cathode after electrification, so that the reaction liquid can react in time after entering the cylinder body 100, including the cathode column 10 inserted by the cylinder head end of the cylinder body 100 as the main body of the reaction, and the cathode column 10 is sealed and fixed The cathode at the head end of the cylinder block 100 holds the cover 20 . A drain hole 11 extending in the axial direction is opened at the end of the cathode column 10 outside the cylinder body 100 , and a liquid inlet hole 12 communicating with the drain hole 11 is opened on the body of the cathode column 10 protruding into the cylinder body 100 .

[0024] The liquid inlet portion includes a liquid inlet column 30 that is sealed and installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com