Interstage combustor with integrated diversion and trapped vortex

A combustion chamber and interstage technology, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of high turbulence pulsation and large air flow velocity, so as to improve the power of the whole machine, increase the temperature rise, and improve the function of gas force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

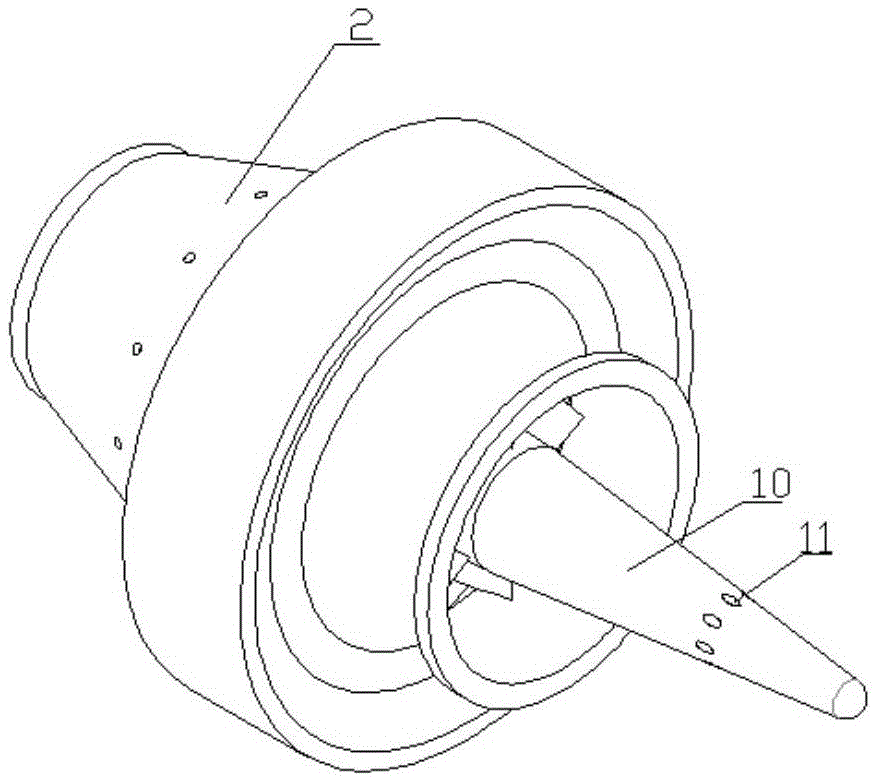

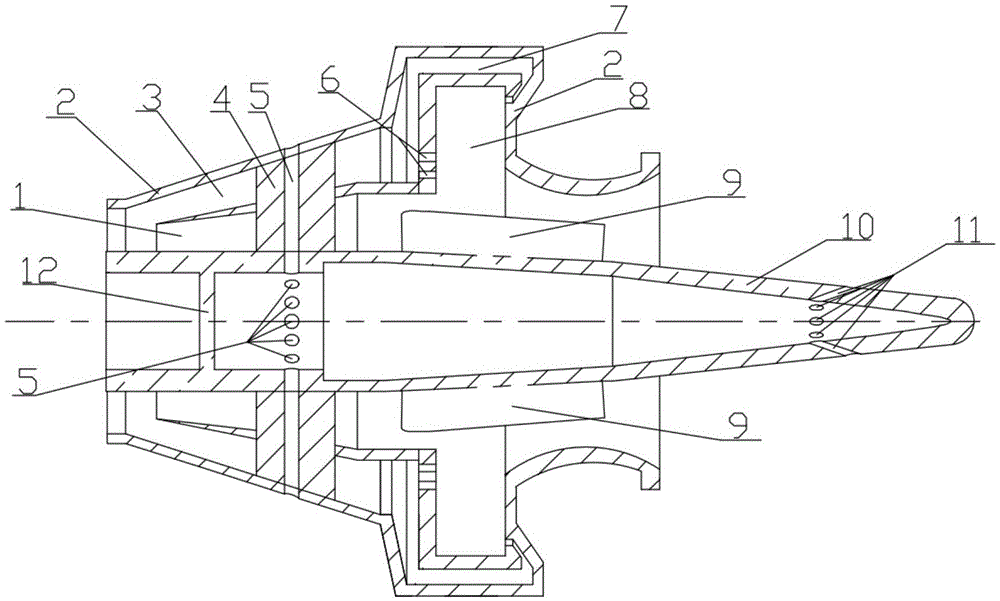

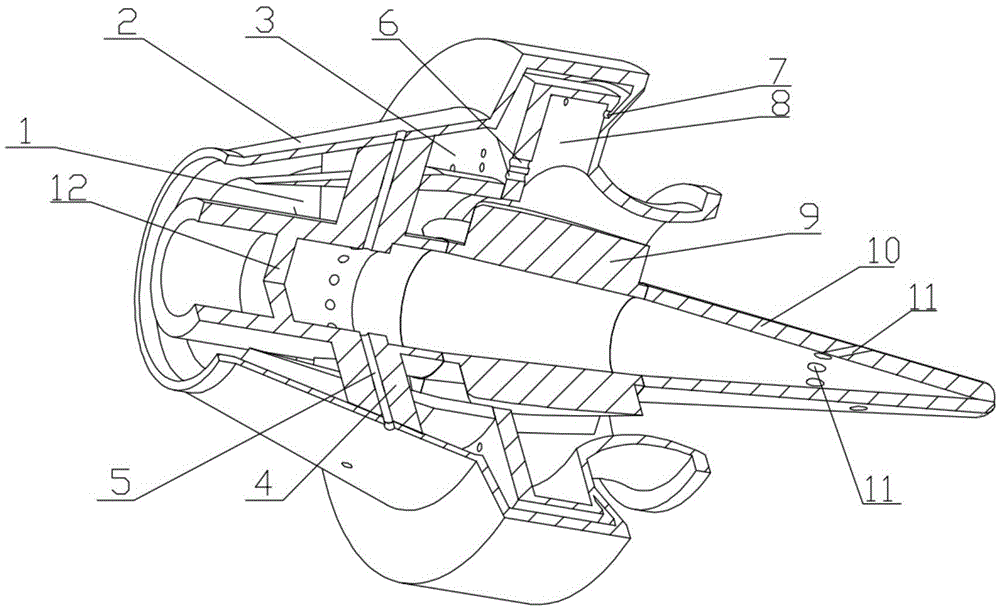

[0030] see Figure 1-11 , the interstage combustor integrated with guide and vortex integration described in this embodiment is provided with a casing 2, a front guide vane 4, a rear guide vane 9 and a tail cone 10; the casing 2 and the front guide vane 4, the rear guide vane 9 and The coccyx 10 is arranged with the central axis and is an integral structure.

[0031] The shell 2 is provided with an axial center through hole, the front of the shell 2 has a trumpet shape with a small front and a large rear, the middle of the shell 2 has a flat cylindrical shape, and the inner cavity of the middle of the shell 2 is provided with a sandwich wall 21 of a bending structure. The interlayer wall 21 of the structure forms an annular cavity 8, the rear part of the housing 2 is in the shape of a waisted column, and the cooling air inlet holes 5 are evenly distributed on the same circumference of the front part of the housing 2.

[0032] The front guide vane 4 is provided with a front gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com