AlFexCrCoNi high-entropy alloy surface ceramization method

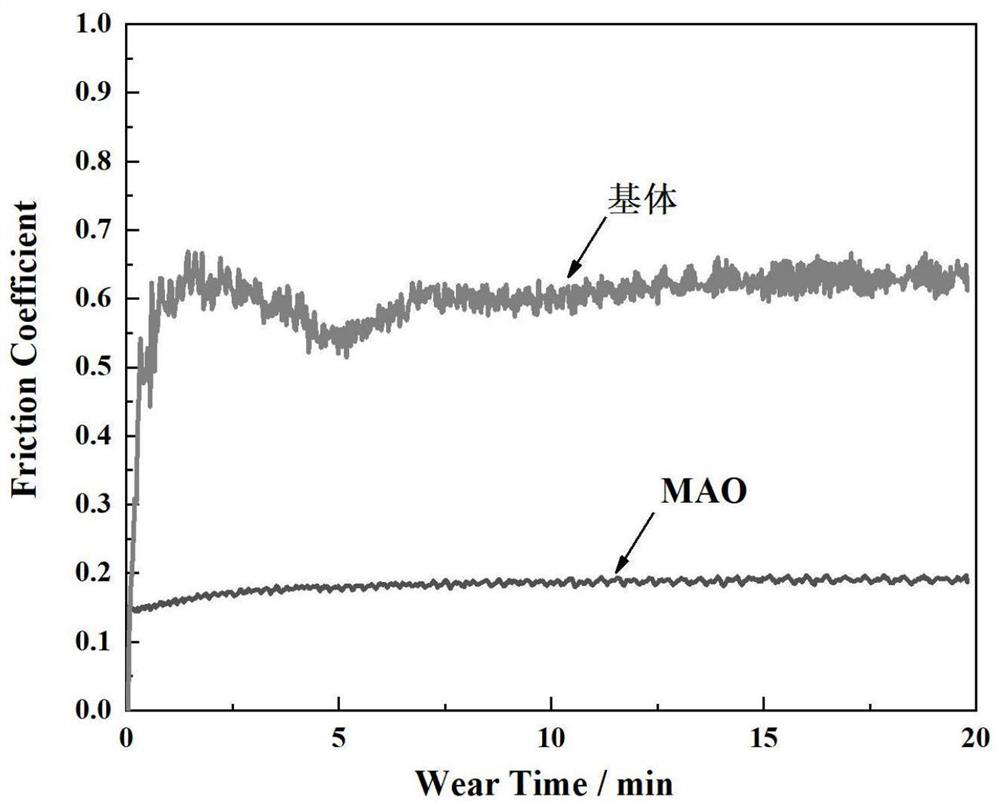

A high-entropy alloy and ceramic technology, applied in surface reaction electrolytic coating, anodizing, electrolytic coating, etc., to achieve the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] AlFe x The preparation method of CrCoNi high-entropy alloy is generally a smelting method, and the smelting method of this embodiment is specifically:

[0033] Select the elemental metals Al, Fe, Cr, Co and Ni with a purity greater than 99.9% for future use;

[0034] with B 2 o 3 Or boric acid is heated separately with elemental metal Al, Fe, Cr, Co or Ni, and then the oxide film on the surface of the elemental metal can be removed, making the purity of the elemental metal higher. When boric acid is used, boric acid decomposes to form boric anhydride, its melting point is 580°C, and the reaction process is 2H 2 BO 3 →B 2 o 3 +2H 2 O; Boron anhydride forms easily soluble borate with oxides of Cu, Zn, Ni and Fe, and the reaction process is MeO+B 2 o 3 →MeO·B 2 o 3 ; To remove the oxide film on the surface of the elemental metal, MeO represents the oxide formed by each elemental metal.

[0035] The heated elemental metals Al, Fe, Cr, Co and Ni are cleaned and d...

Embodiment 1

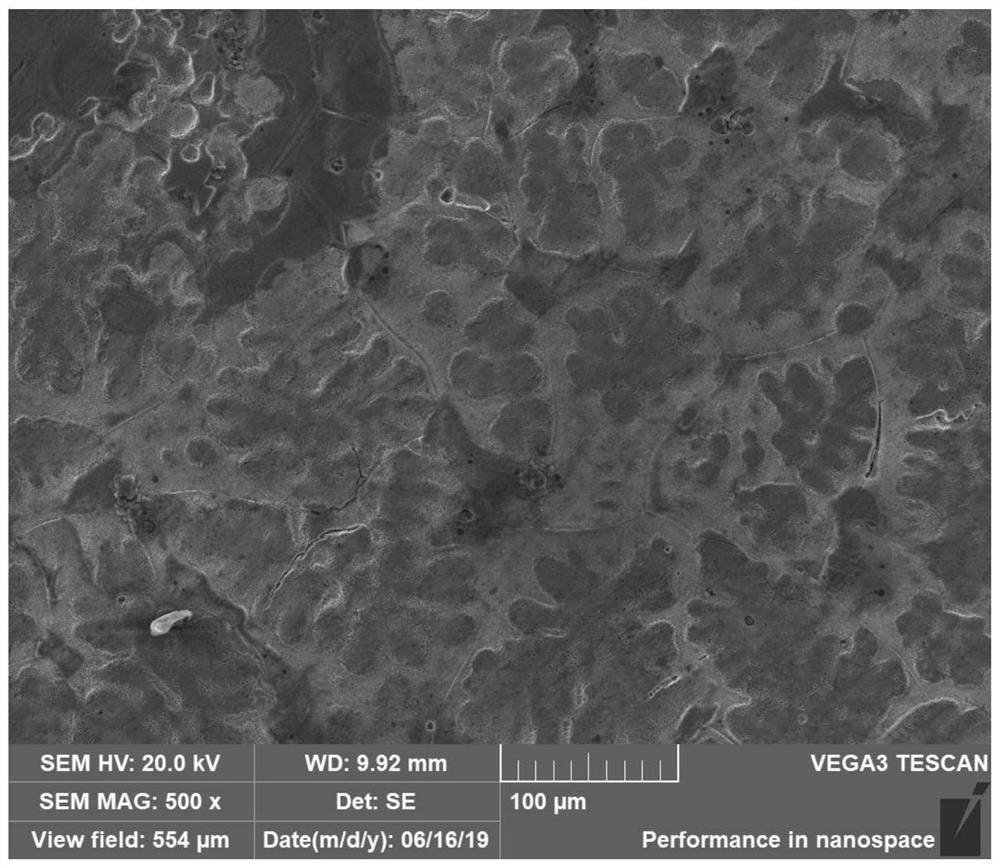

[0044] In this example, in AlFe 0.3 The black ceramic layer is prepared on the surface of CrCoNi high-entropy alloy, that is, the micro-arc oxidation ceramic layer is prepared in the electrolyte, so that the surface layer of the high-entropy alloy matrix is uniformly formed in situ containing Fe 3 o 4 A ceramic layer composed of various oxides, the thickness of the ceramic layer is 5 μm.

[0045] The above AlFe 0.3 The preparation method of the black ceramic layer on the surface of CrCoNi high-entropy alloy comprises the steps:

[0046] Step 1: Select the following five high-purity elements Al, Fe, Cr, Co, and Ni (purities are all above 99.9%), and mix them according to the chemical composition of the molar ratio 1:0.3:1:1:1: , among them, Al chooses pure aluminum particles, prepares 10.11g, Fe chooses pure iron particles, prepares 6.28g, Cr chooses pure chromium particles, prepares 19.49g, Co chooses pure cobalt particles, prepares 22.09g, Ni chooses pure nickel particle...

Embodiment 2

[0055] In this example, AlFe 0.5 The black ceramic layer on the surface of the CrCoNi high-entropy alloy, that is, the micro-arc oxidation ceramic layer is prepared in the electrolyte, so that the surface layer of the high-entropy alloy matrix is formed in situ containing Fe 3 o 4 A ceramic layer composed of various oxides, the thickness of the ceramic layer is 15 μm.

[0056] The above AlFe 0.5 The preparation method of the black ceramic layer on the surface of CrCoNi high-entropy alloy comprises the steps:

[0057] Step 1: Select high-purity Al, Fe, Cr, Co, Ni (all above 99.9% in purity) metals, and mix them according to the chemical composition of 1:0.5:1:1:1: Among them, Al is selected Pure aluminum particles, prepare 9.61g of materials, Fe selects pure iron particles, prepares 9.94g, Cr selects pure chromium particles, prepares 18.52g, Co selects pure cobalt particles, prepares 20.99g, Ni selects pure nickel particles, prepares 20.91g, will prepare The good raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com