Combined sleeper

A combined, sleeper technology, applied in the field of rail transit, can solve the problems of poor elasticity of the rail bearing platform 13, difficulty in adjusting the geometry of the track, and inability to adjust the geometry of the track, so as to achieve the effect of easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

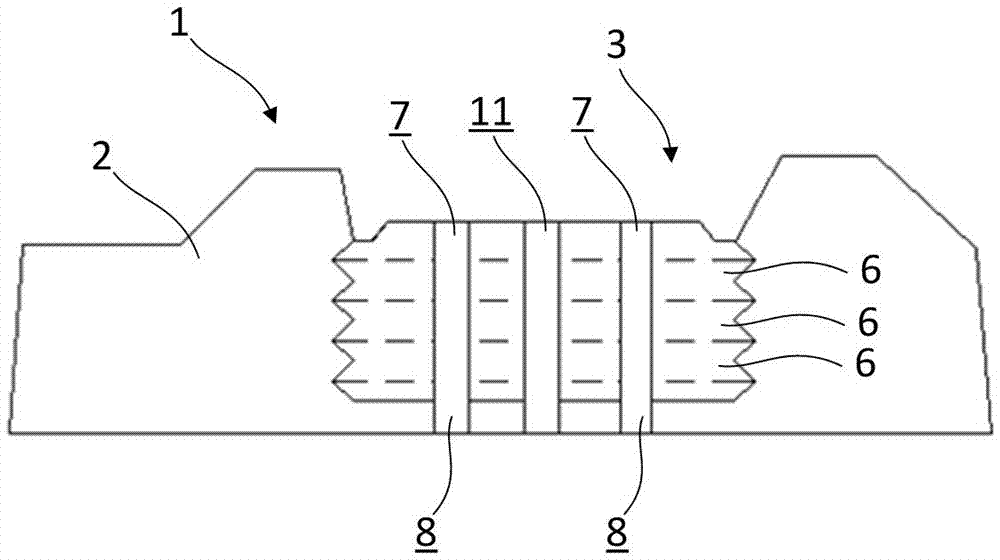

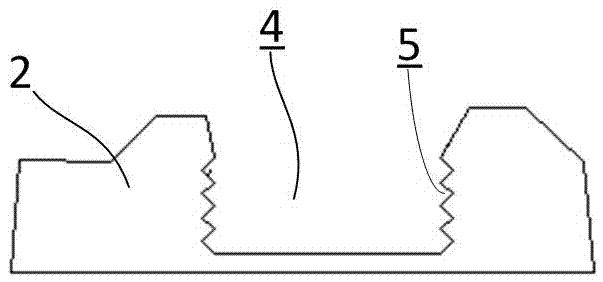

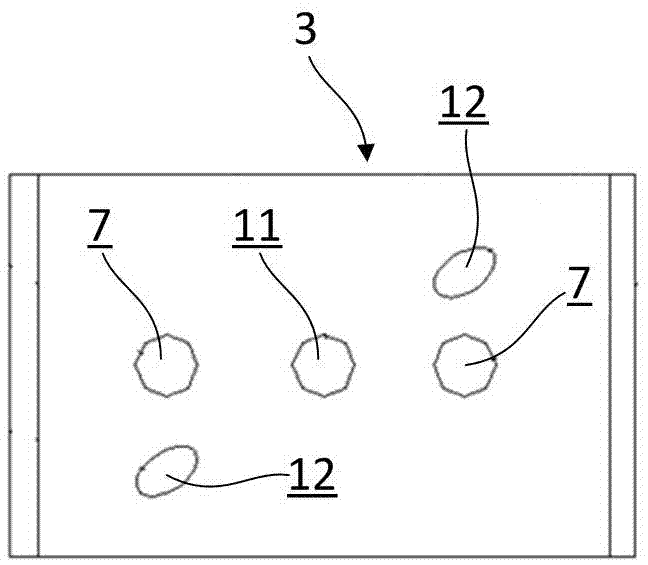

[0026] Example: such as figure 1 , 2 As shown, this embodiment specifically relates to a combined sleeper 1, the combined sleeper 1 includes a sleeper main body 2 and a rail bearing plate 3, the upper surface of the sleeper main body 2 is provided with a rail bearing groove 4, and the rail bearing plate 3 is along the horizontal direction Set in the rail groove 4.

[0027] Such as figure 1 , 2 As shown, the side wall of the rail groove 4 is provided with a rail plate groove 5, the rail plate groove 5 extends along the horizontal direction, and the edge shape of the rail plate 3 is adapted to the rail plate groove 5; when assembling , the edge of the rail plate 3 is clamped in the slot 5 of the rail plate; in this embodiment, the slot 5 of the rail plate is sawtoothed, and the edge of the rail plate 3 is sawtoothed to match it; The rail plate slot 5 can facilitate the installation and positioning of the rail plate 3 and prevent the rail plate 3 from moving in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com