Method for lap jointing of longitudinal cold joints of asphalt concrete pavement

A kind of asphalt concrete, vertical technology, applied in the seam treatment of asphalt concrete pavement, the field of longitudinal cold joint lap joint of asphalt concrete pavement, can solve the problems of difficult treatment, cracks and water leakage at the joints, and achieve the guarantee Driving comfort, ensuring driving safety, and the effect of simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A method for lapping longitudinal cold joints of asphalt concrete pavement, characterized in that: the method includes the following processing steps:

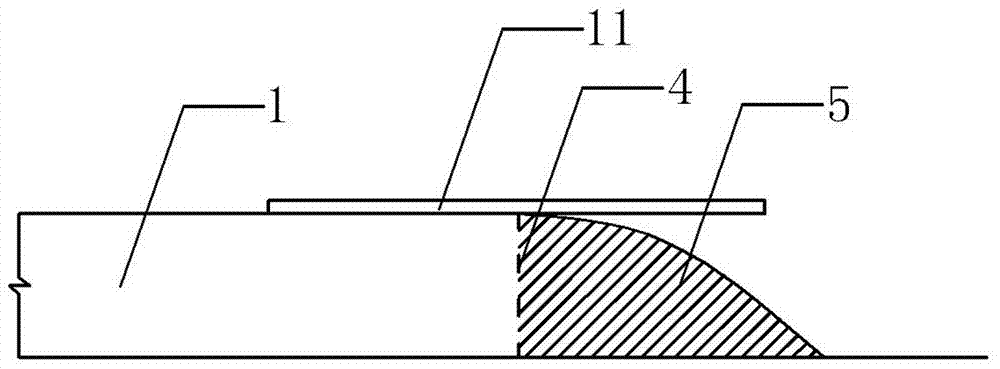

[0035] 1) if figure 1 As shown, the edge of the half pavement 1 laid in advance is broken: use a ruler 11 to measure the insufficient part of the road surface thickness, and plan the insufficient thickness part;

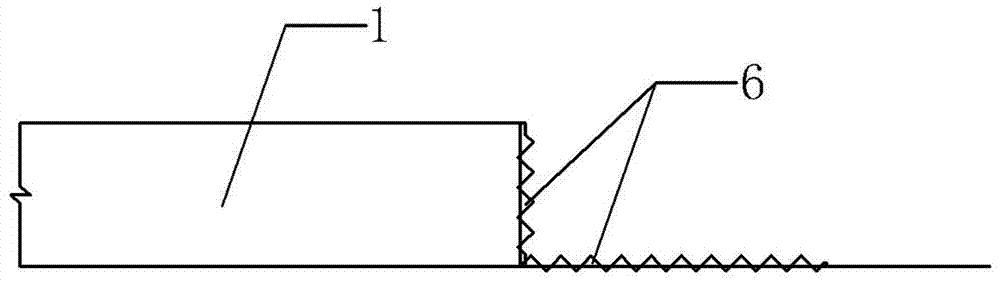

[0036] 2) if figure 2 As shown, the overlapping joints are coated with sticky layer oil: apply asphalt sticky layer oil 6 on the rough facade after the edge of the previously laid half pavement 1 has been manually planed off and on the surface of the lower bearing layer covered by the planed material;

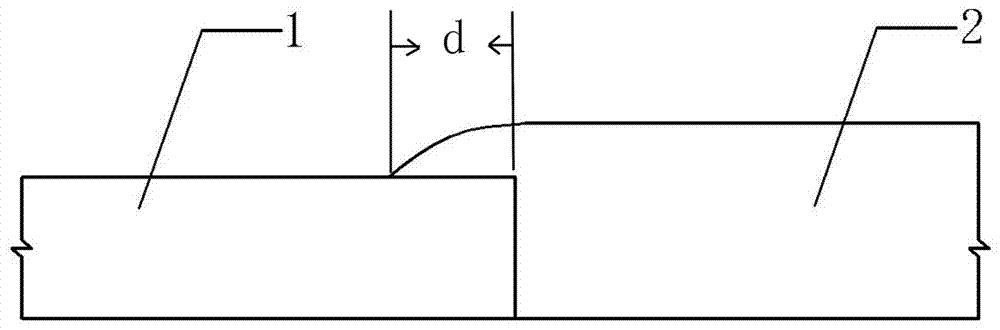

[0037] 3) if image 3 As shown, the paving of the second half of the pavement and the lapping of the mixture: when paving the second half of the pavement with a paver, the newly paved pavement mixture is lapped with the previously laid half of the pavement, relying on the high temperature of the newly paved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com