Anti-blocking technique for stored ores of high orepass during phosphate ore mining

A technology for chute and phosphate rock, which is applied in the field of high chute storage and anti-blocking technology in phosphate rock mining, can solve problems such as no reference cases, achieve obvious energy saving effect, prevent chute blockage, and prevent dredging chute blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

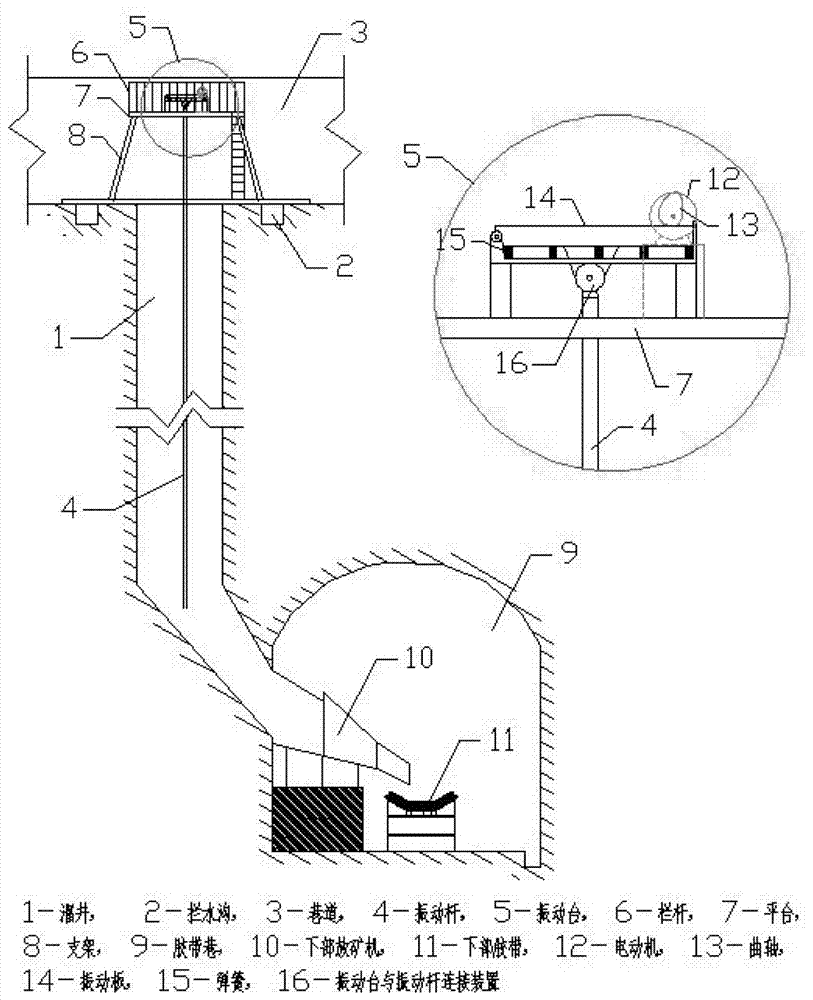

[0026] The invention relates to an ore storage and anti-clogging process in a high-speed chute in phosphate rock mining. A vibrating table is arranged on the upper mouth of the chute, and a vibrating rod is extended downward into the chute. When the vibrating table is working, the vibrating rod vibrates the slag in the chute. Its main technological process is as follows:

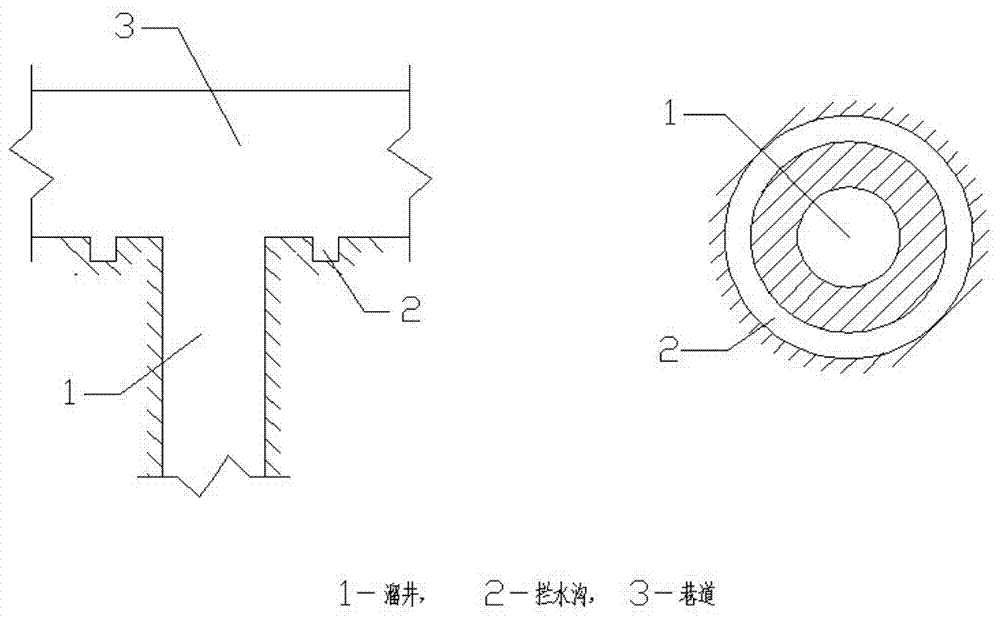

[0027] 1) Construct a drainage ditch around the upper wellhead of the chute. Avoid water flooding into the chute, accelerate the hydration of the argillaceous shale in the slag and the sinking of the dolomite powder, and the slag will harden and cause the blockage of the chute.

[0028] 2) Fabricate and install a vibration table at the upper wellhead of the chute. The vibrating table is installed directly above the upper mouth of the chute, on a bracket at a height of 2.5 meters from the grid screen. The base of the vibrating table is not less than 1.5 meters away from the edge of the chute and is on a stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com