Patents

Literature

35 results about "Block techniques" patented technology

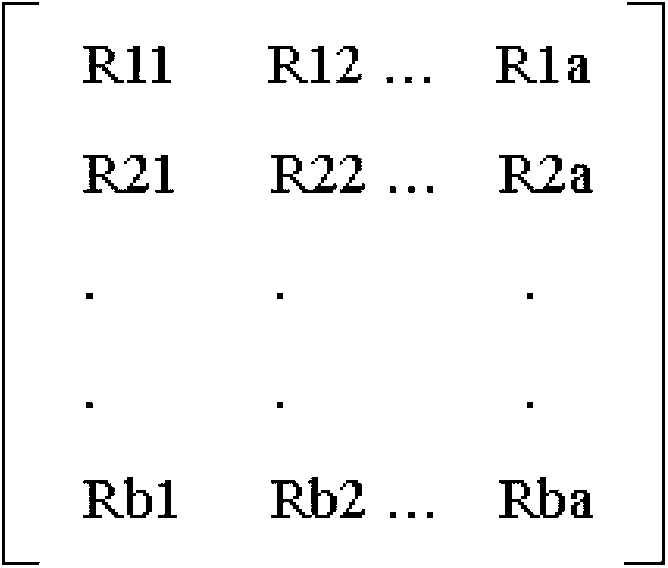

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

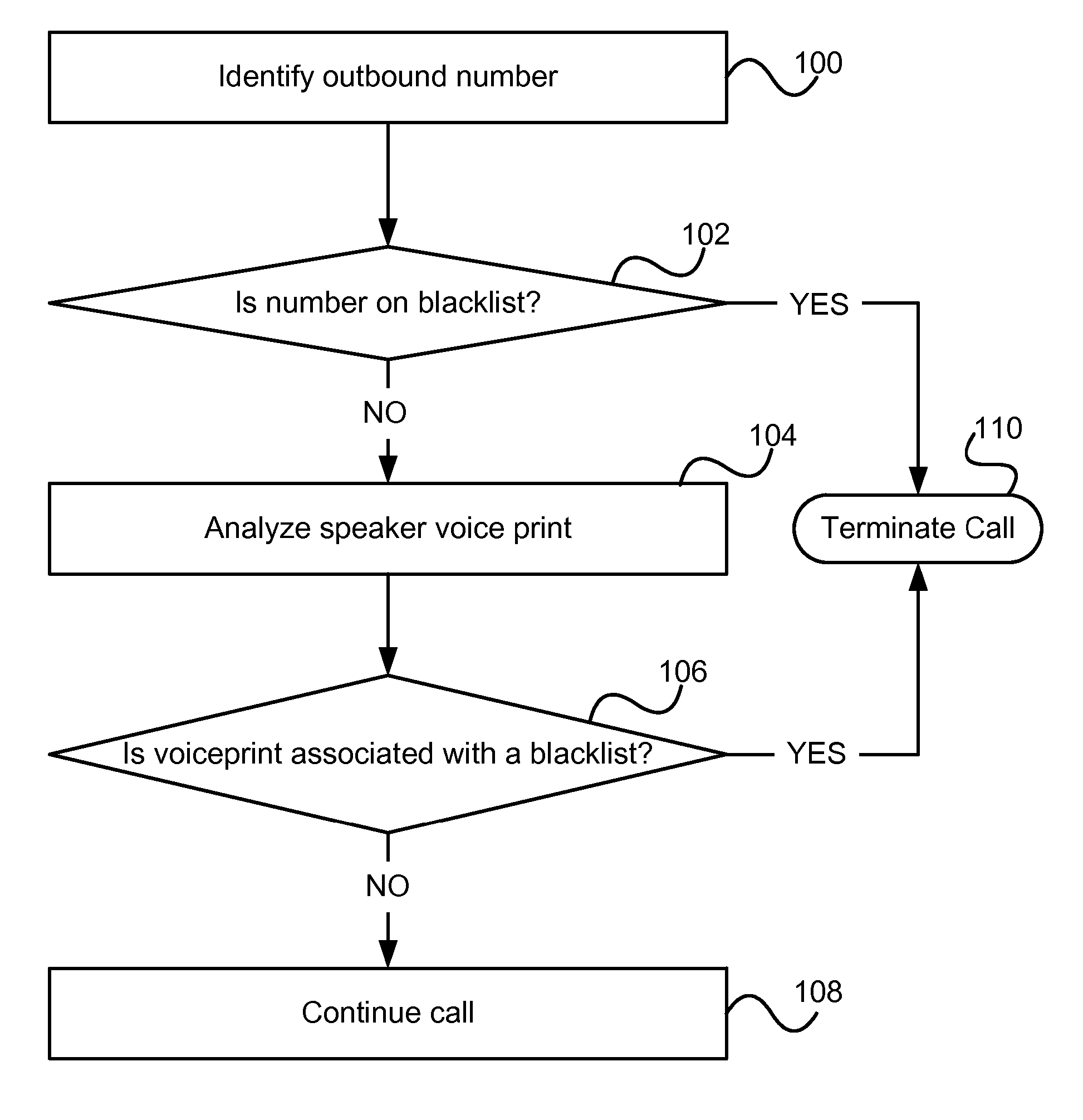

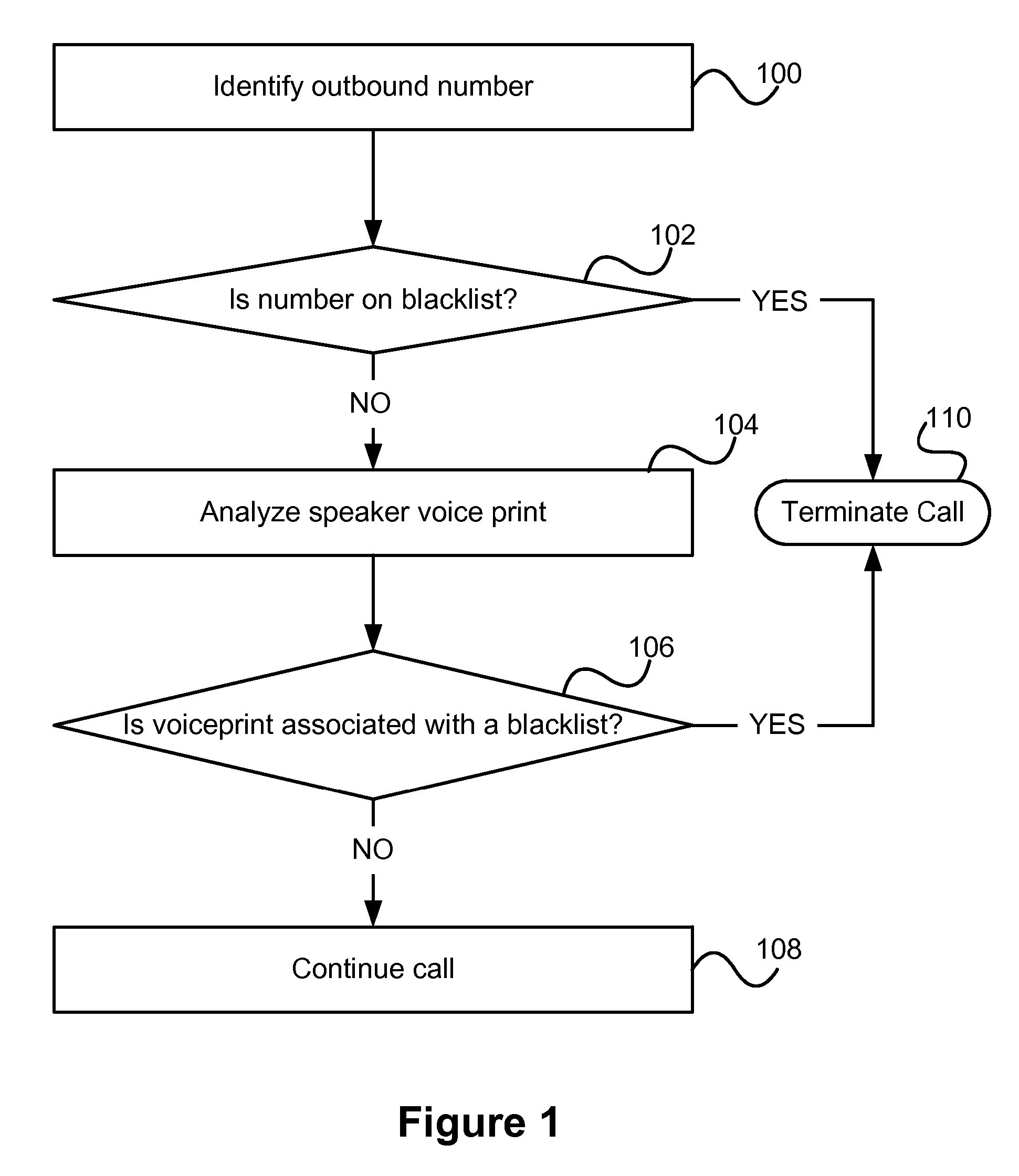

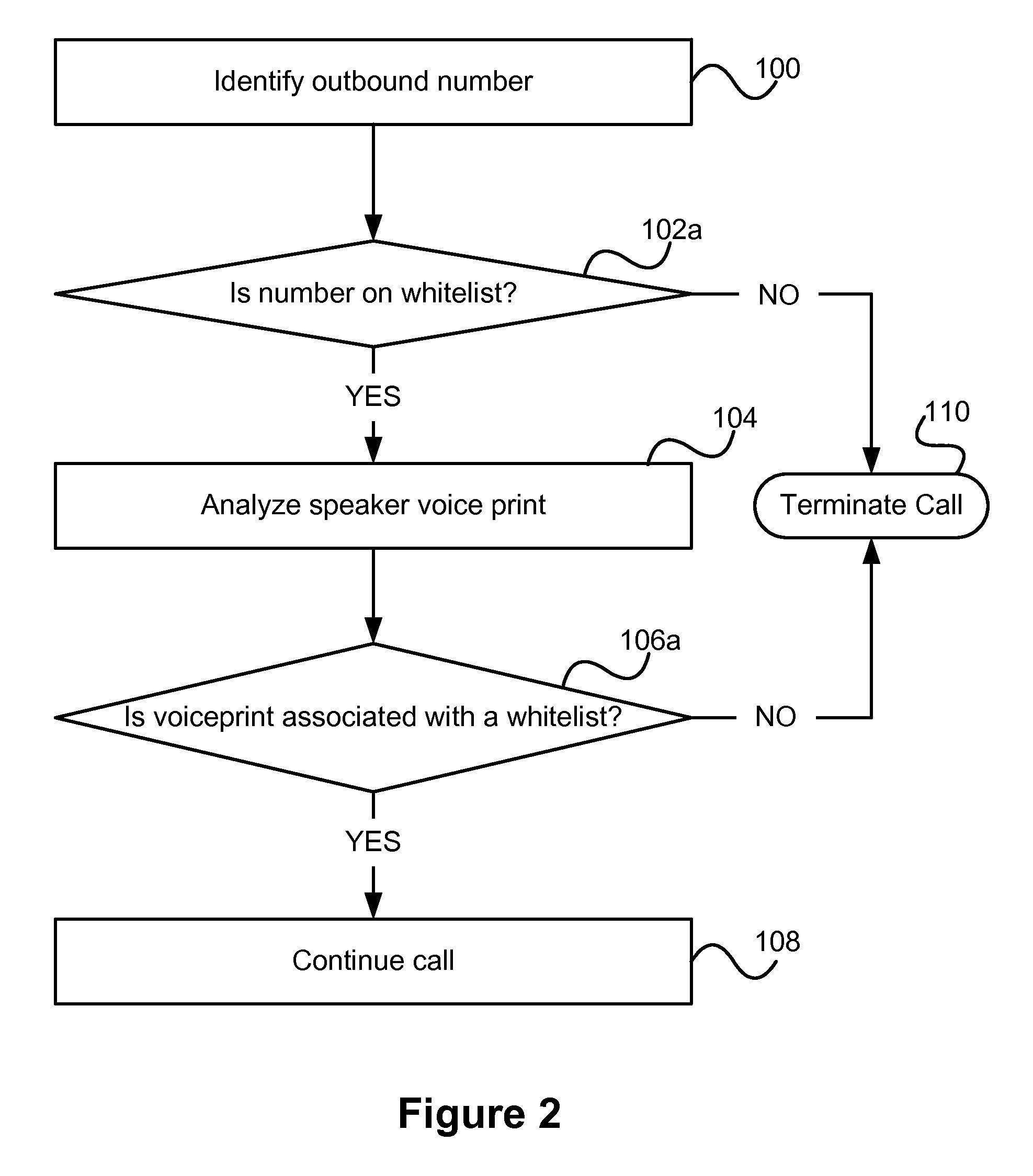

Call transfer detection method using voice identification techniques

InactiveUS20070041517A1Unauthorised/fraudulent call preventionAutomatic call-answering/message-recording/conversation-recordingCall forwardingBlock techniques

A system and method for call handling make use of voiceprinting techniques to identify parties on the call and then allow call functions to be performed in accordance with the identified parties. These systems and methods can be used in conjunction with known call analysis and blocking techniques to reduce the likelihood that a caller from a restricted environment can connect to an unauthorized party by calling an authorized number and then having the call redirected, conferenced or otherwise transferred to the unauthorized party.

Owner:PIKA TECH

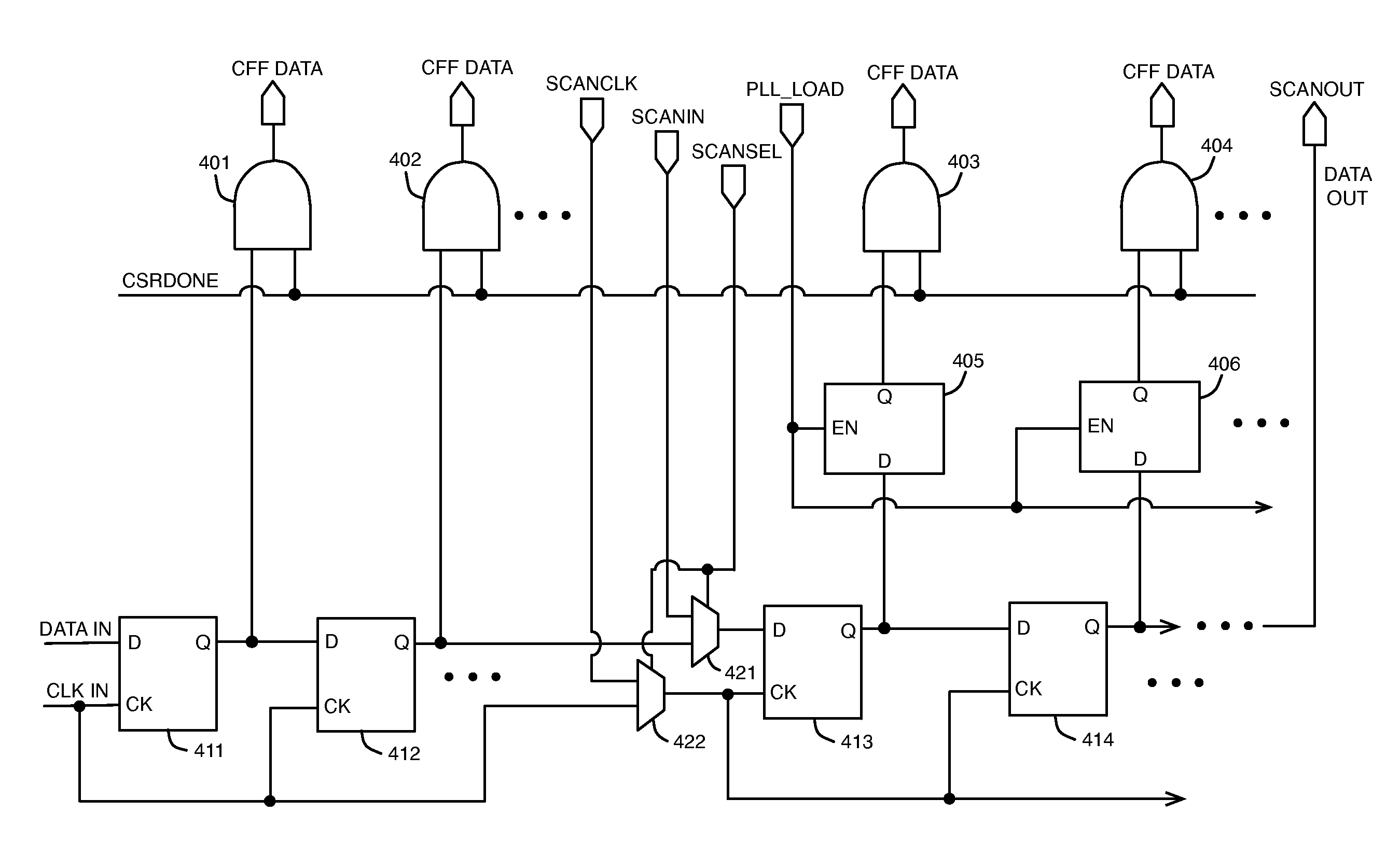

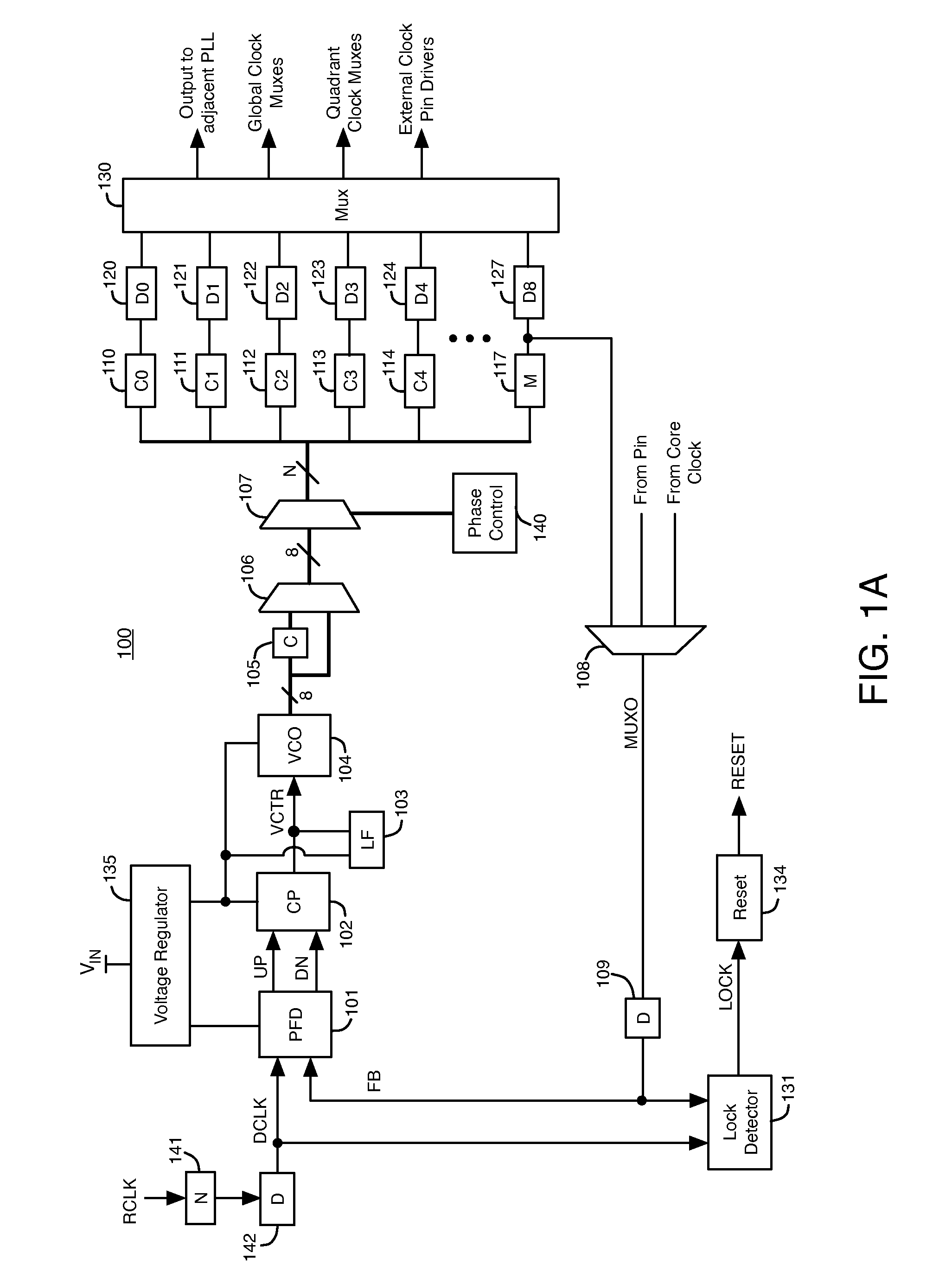

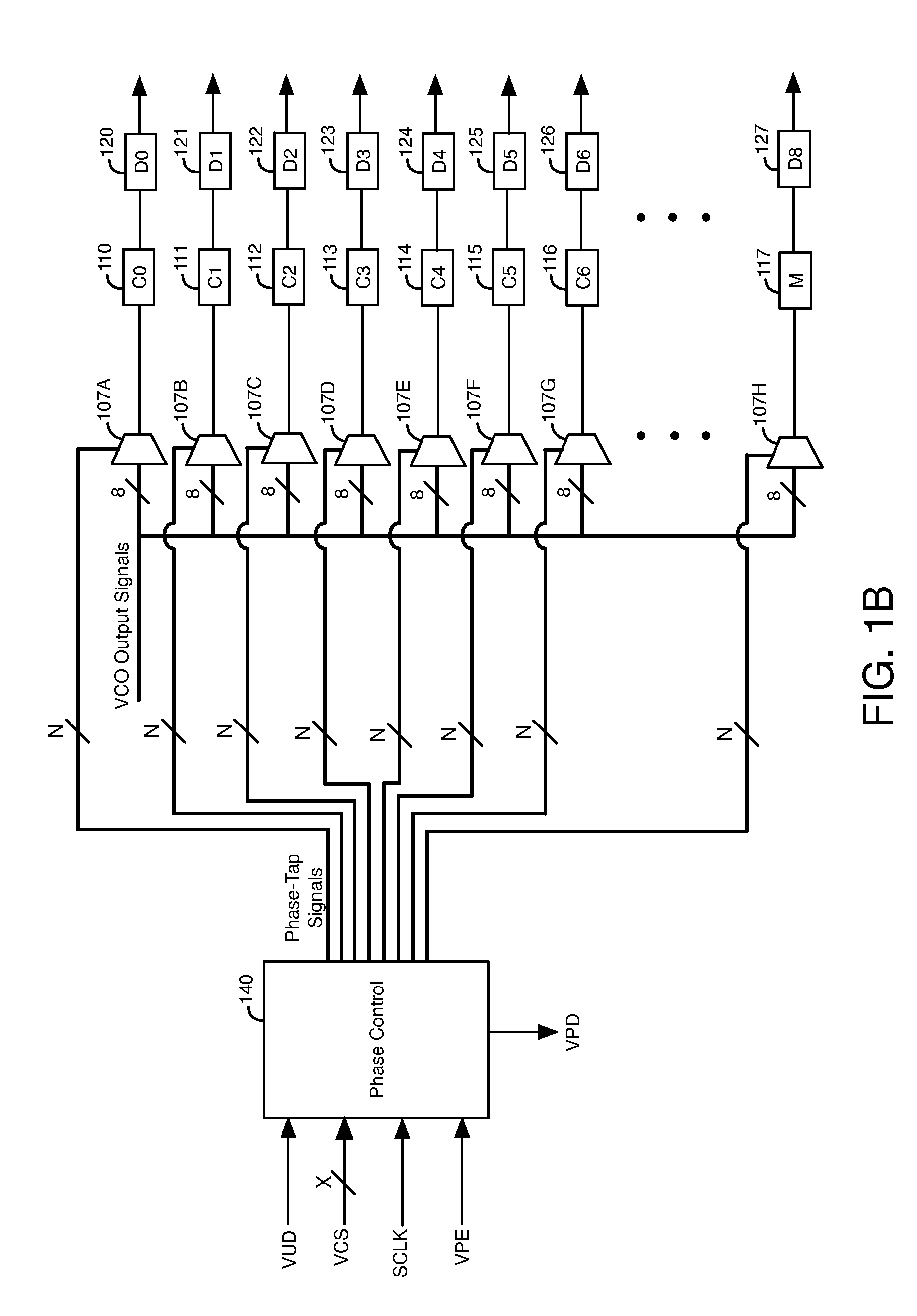

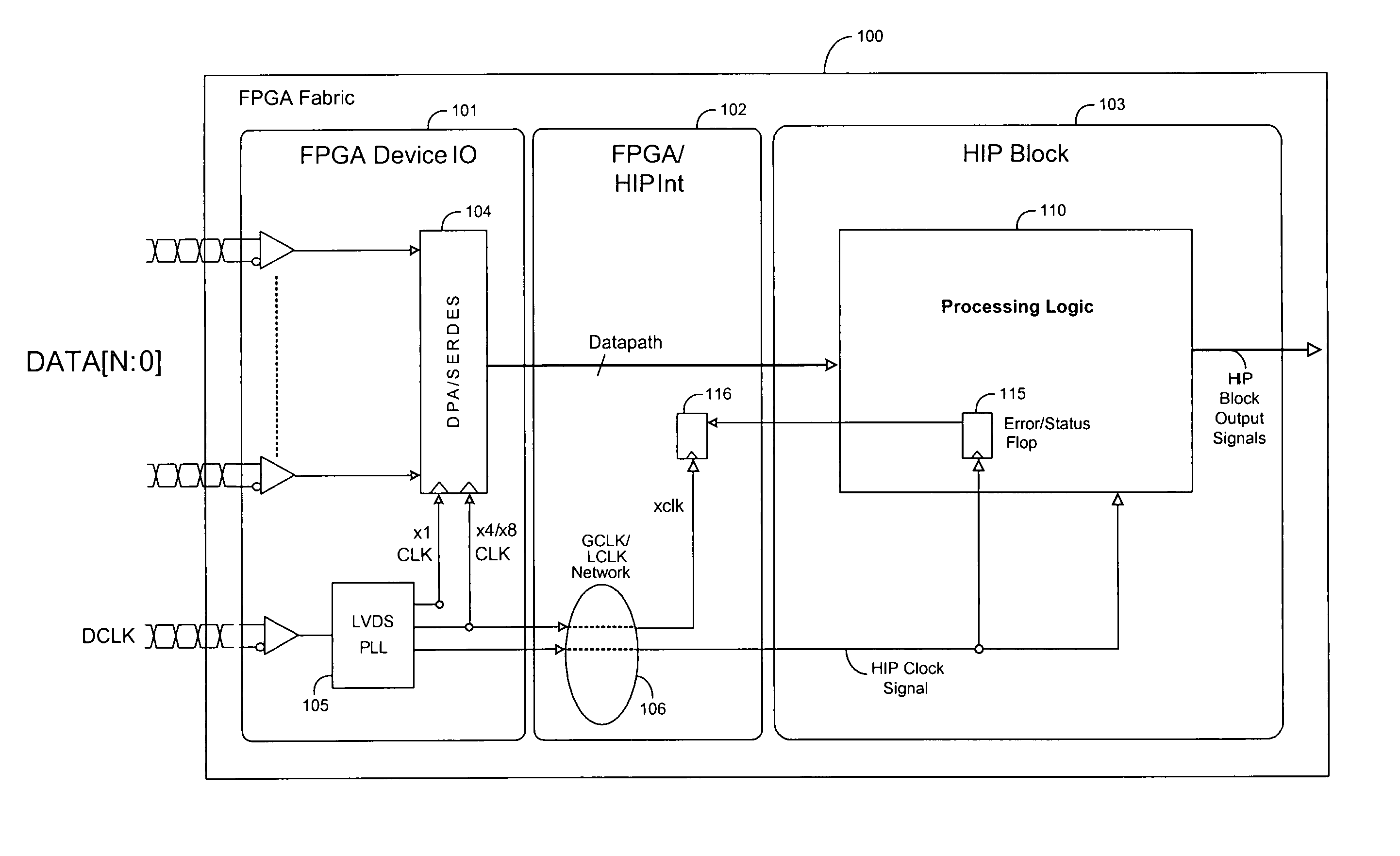

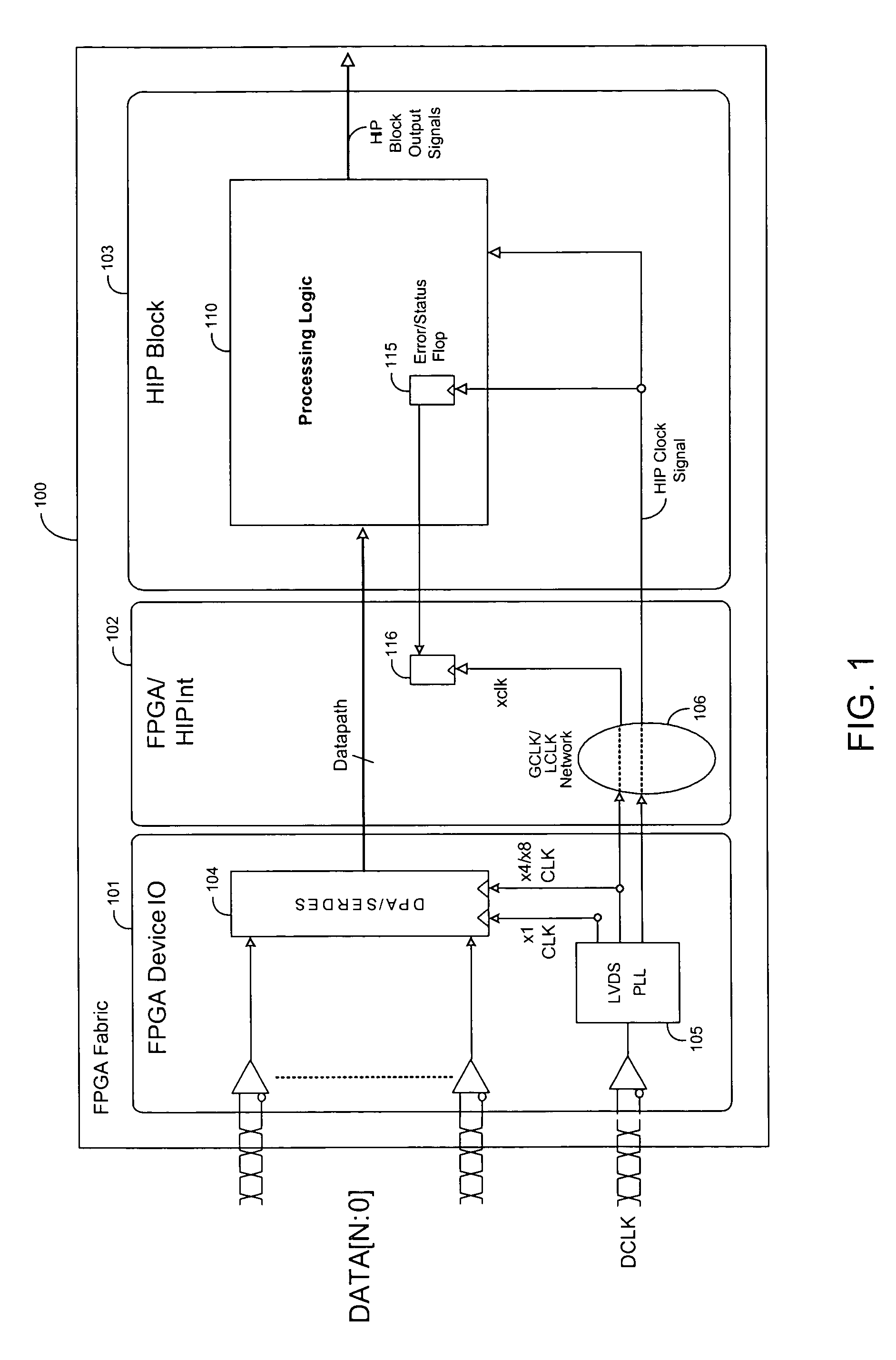

Techniques for reconfiguring programmable circuit blocks

InactiveUS7532029B1Pulse automatic controlLogic circuits using elementary logic circuit componentsPhase shiftedProcessor register

Techniques are provided for dynamically reconfiguring programmable circuit blocks on integrated circuits during user mode. First configuration bits are loaded from first configuration scan registers into second configuration scan registers during configuration mode. The first configuration bits are used to configure programmable settings of a programmable circuit block. During user mode, second configuration bits are transmitted from a pin to the second configuration scan registers without transferring the second configuration bits through the first configuration scan registers. The second configuration bits are used to reconfigure the programmable settings of the programmable circuit block during the user mode. Also, phase shift circuitry can dynamically shift the phase of an output clock signal by selecting a different input clock signal. The phase shift circuitry has a delay circuit that allows the phase of a high frequency clock signal to be shifted without causing glitches in the clock signal.

Owner:ALTERA CORP

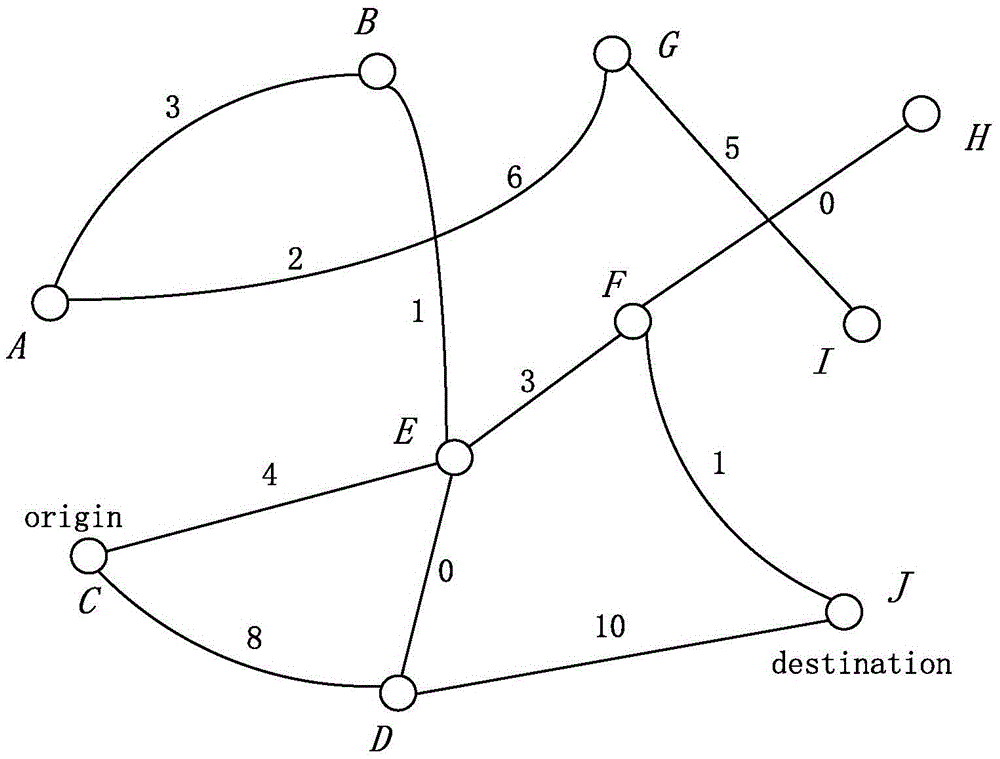

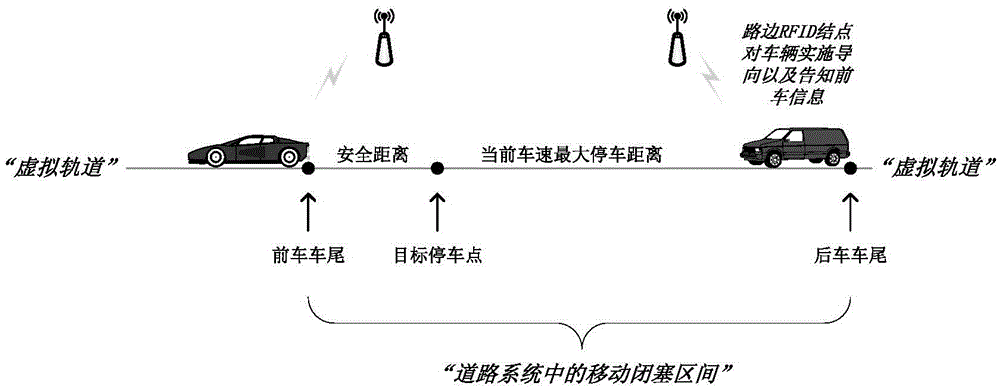

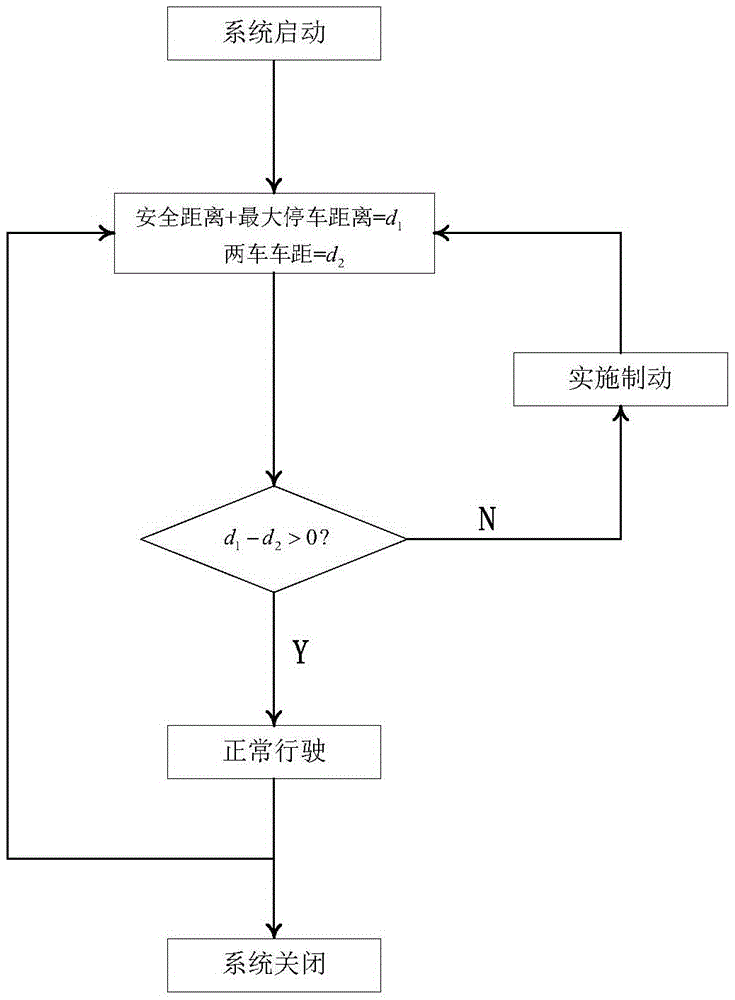

Unmanned method and system based on virtual track and moving block technique

ActiveCN105644559AEasy to set upRequirements for reduced perceptionAnti-collision systemsAutomatic initiationsSystems designSimulation

The invention discloses an unmanned method and system based on a virtual track and the moving block technique. The unmanned method comprises the steps that S1, the virtual track of an unmanned vehicle is built; S2, the safe distance between the current vehicle and a front vehicle is acquired; and S3, on the basis of comparison between the actual distance based the current vehicle and the front vehicle and the sum of the safe distance and the maximum parking distance, the current vehicle is subjected to running control. According to the unmanned method and system based on the virtual track and the moving block technique, the virtual track and the moving block technique based on communication are introduced into the road unmanned system, various random phenomena occurring in the road vehicle running process can be effectively dealt, accordingly, a disorganized driving mode at first becomes orderly, and the design complexity of the system and the cost of the unmanned vehicle are greatly reduced.

Owner:BEIJING JIAOTONG UNIV

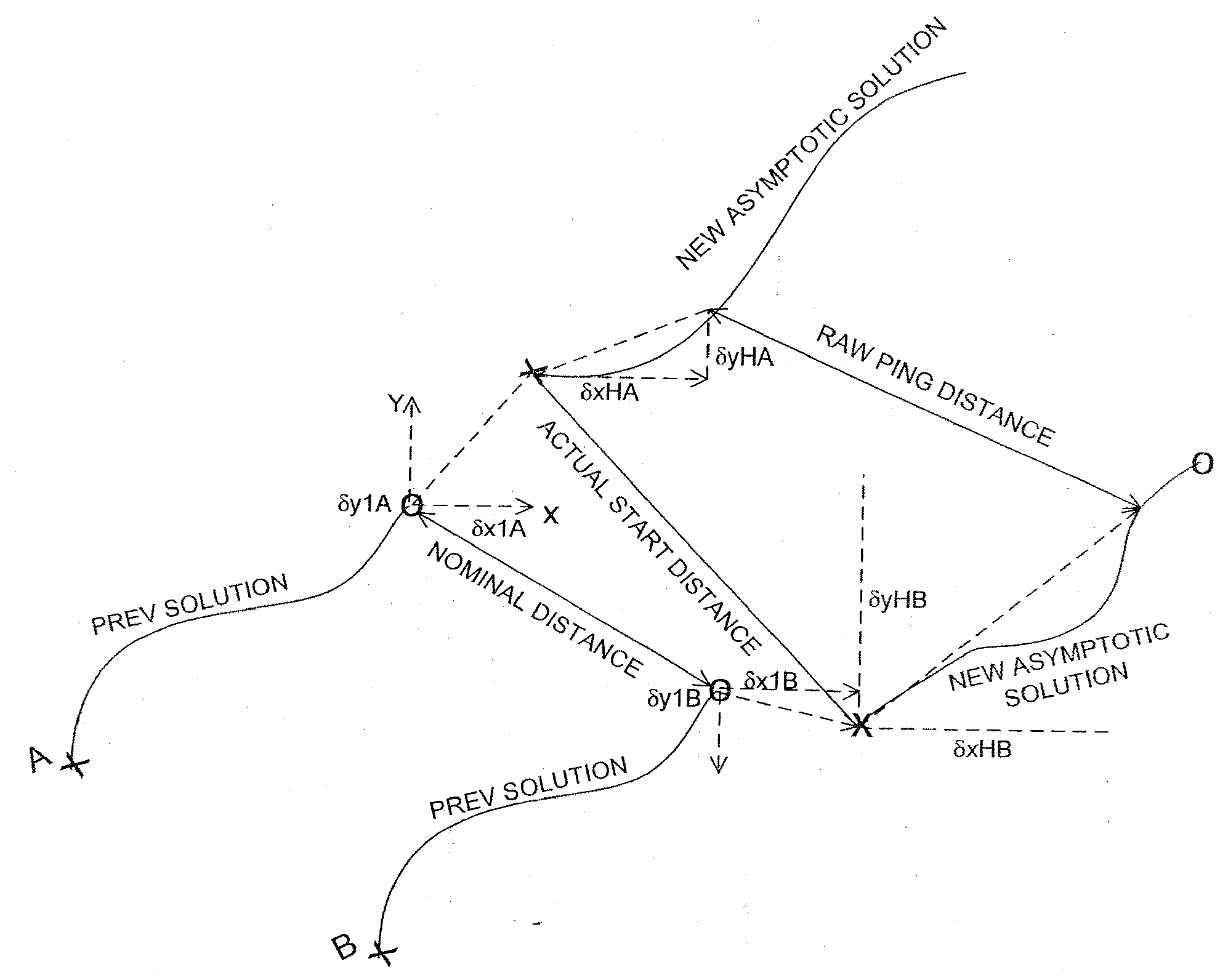

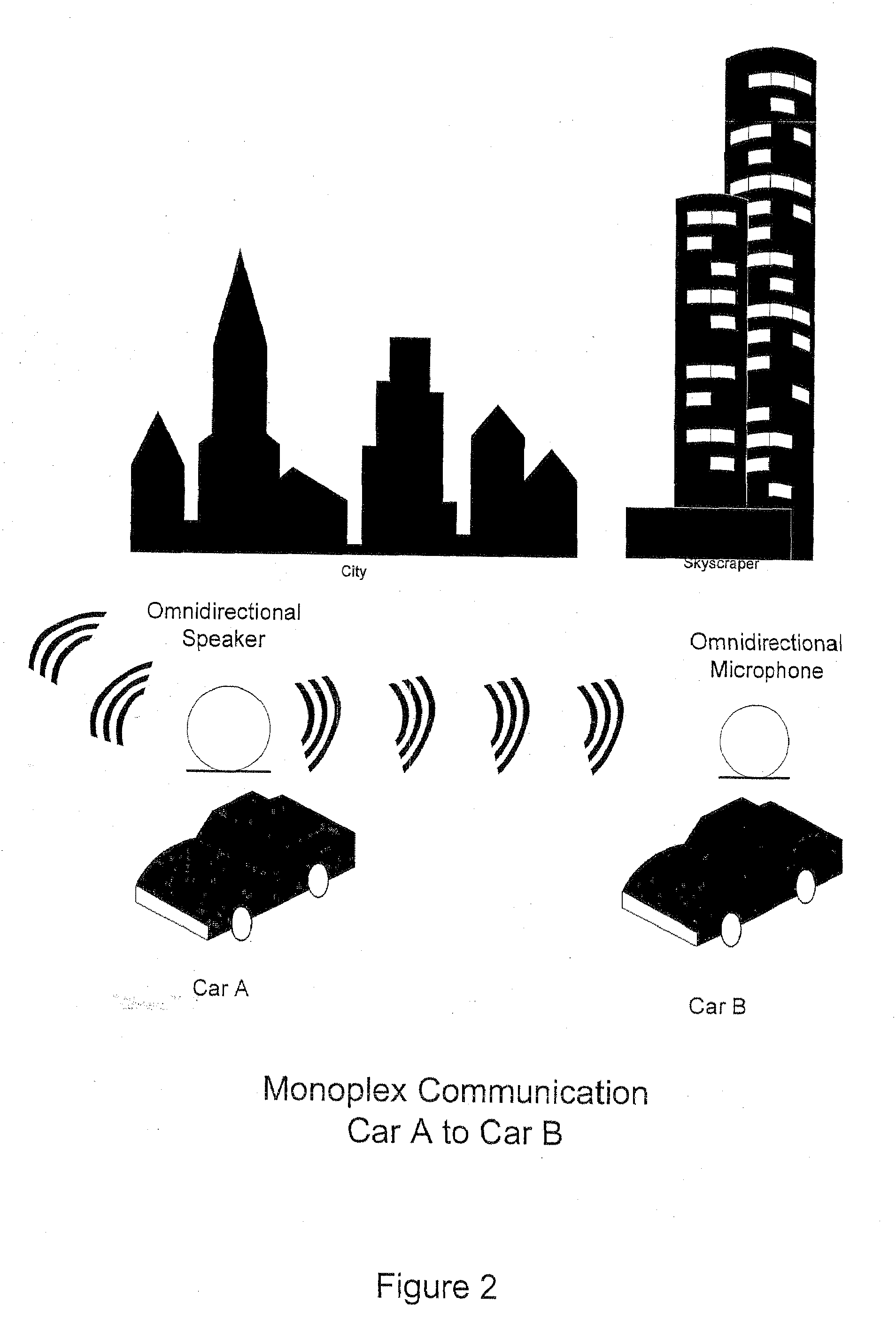

Harmonic block technique for computing space-time solutions for communication system network nodes

ActiveUS20100045531A1Large user base for WiFi-based positioning devicesDirection finders using radio wavesPosition fixationCommunications systemHarmonic

A space-time calibration system and method implement space-time solutions, in which, in one preferred embodiment, a single node determines its own space-time solutions based on other network nodes with which the single node communicates. In other preferred embodiments, space-time solutions for the node can be generated using other resources in the network. The disclosed system and method enable reliable, precise object positioning particularly for environments where the Global Positioning System (GPS) is blocked or subject to interference such as within the urban core.

Owner:DIGIMARC CORP

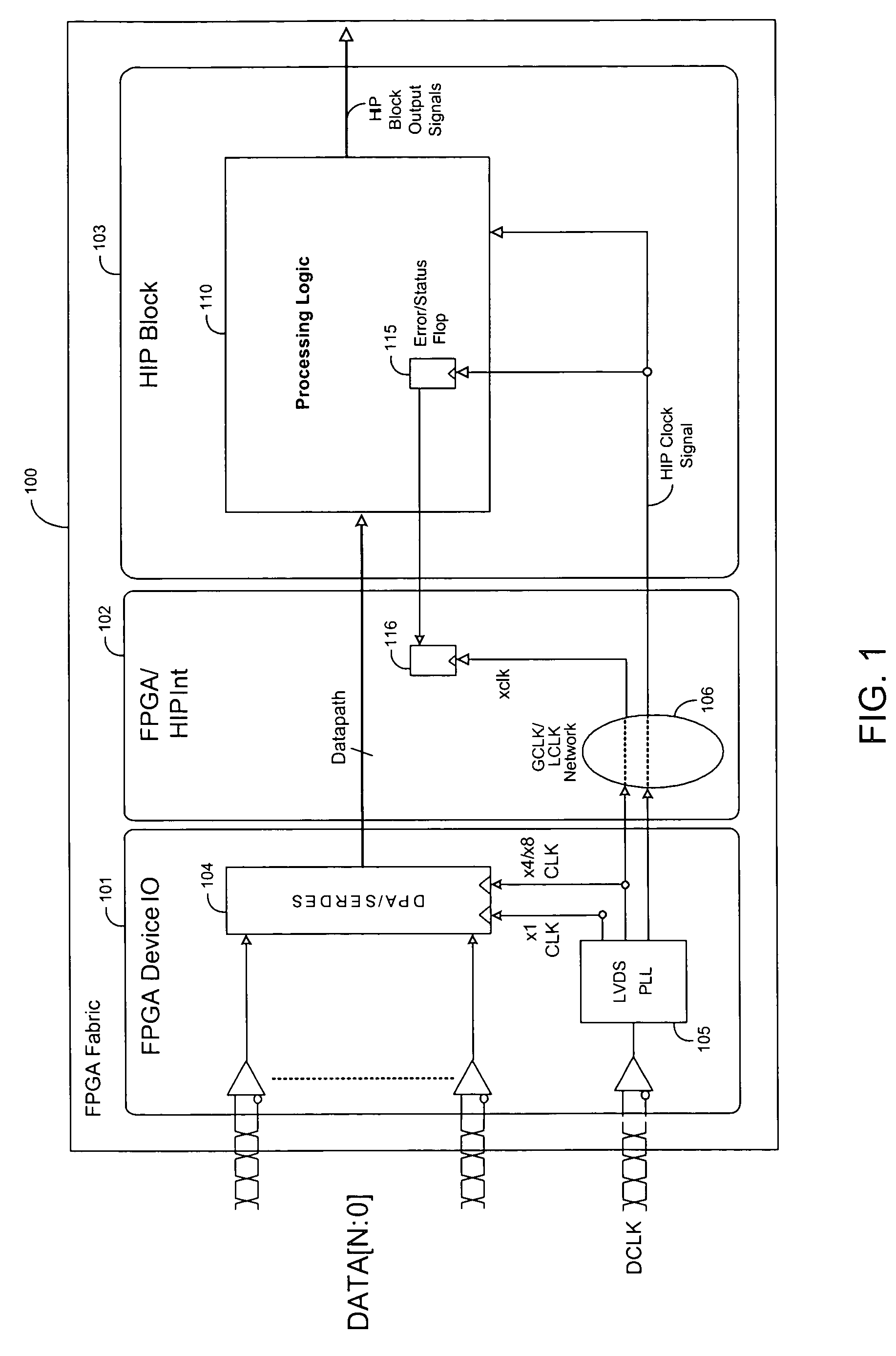

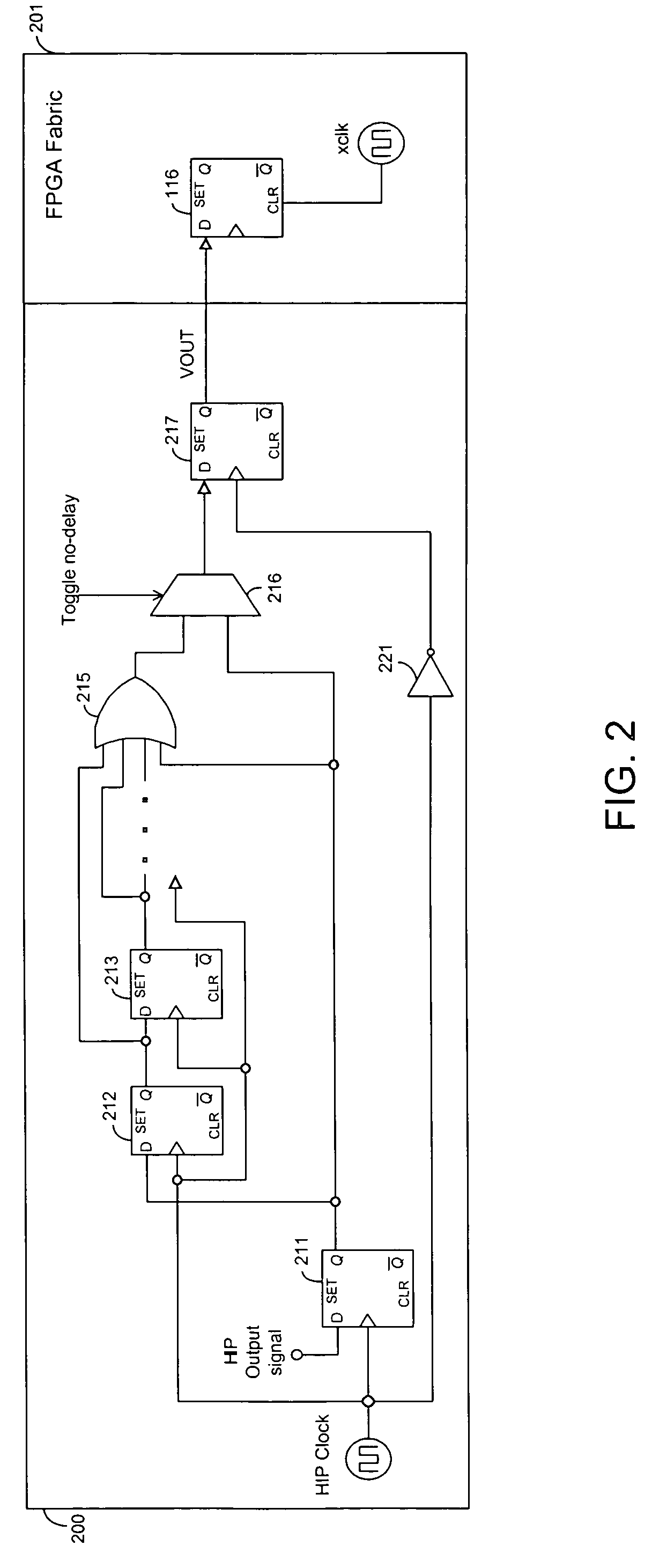

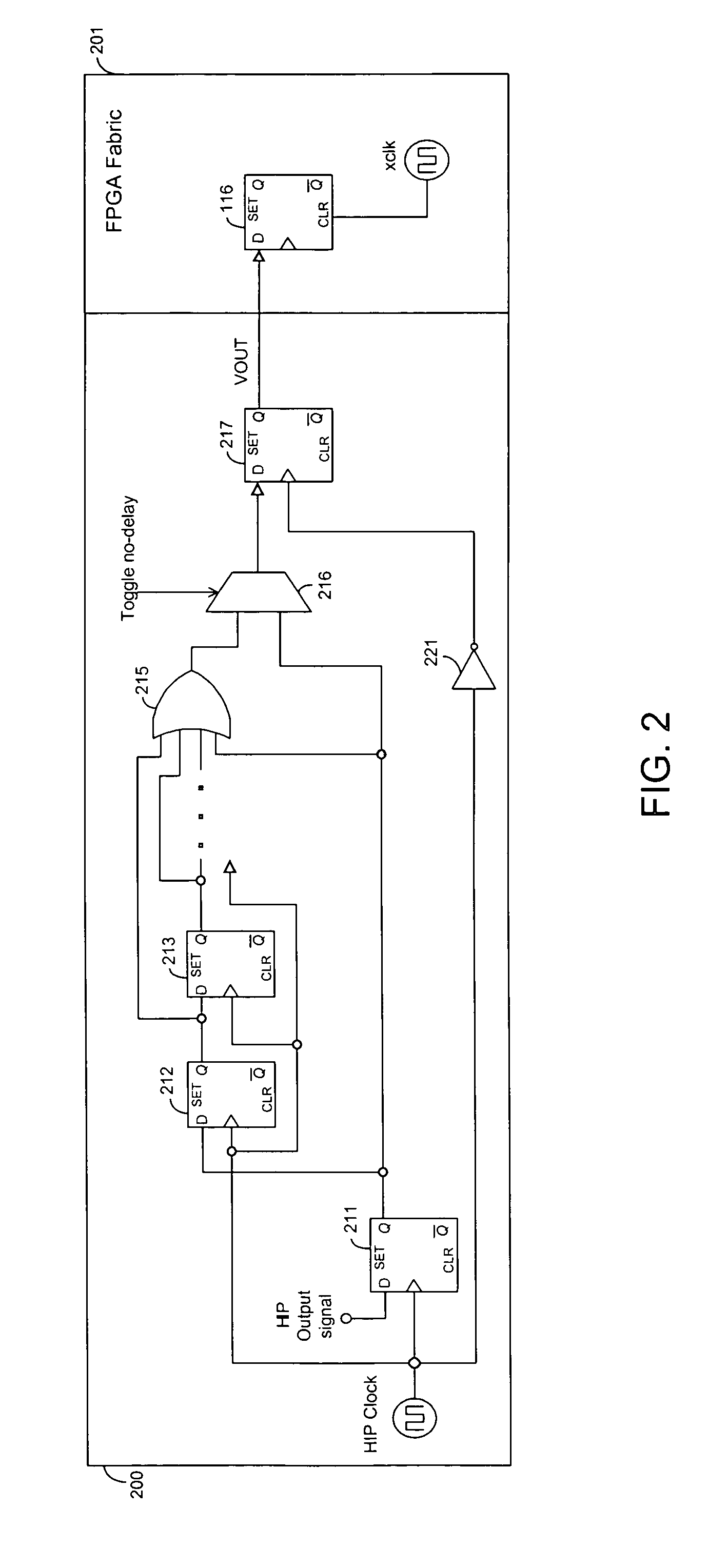

Output reporting techniques for hard intellectual property blocks

Techniques for reducing the frequency of an output signal from a hard intellectual property (HIP) block on an integrated circuit are provided. By reducing the frequency of the output signal, circuit blocks in the integrated circuit that operate at a lower frequency than the HIP block are able to capture the output signal. A plurality of serially coupled flip-flops store values of an HIP output signal during each period of the output signal. Logic circuitry then generates a lower frequency HIP output signal in response to the values stored in the flip-flops. Also, a flip-flop can generate a heartbeat signal that is used to determine whether a signal within an HIP block is operating properly.

Owner:ALTERA CORP

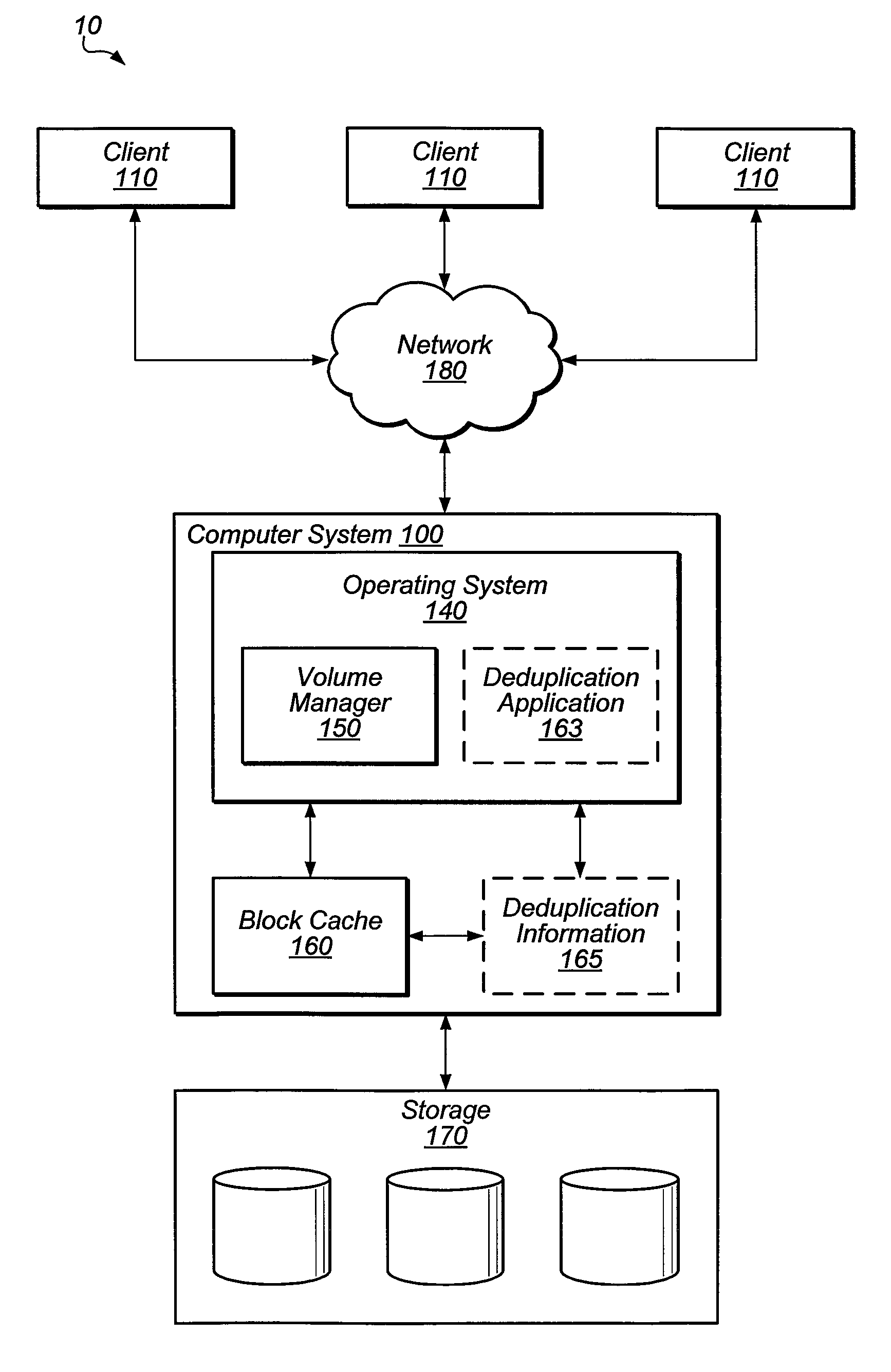

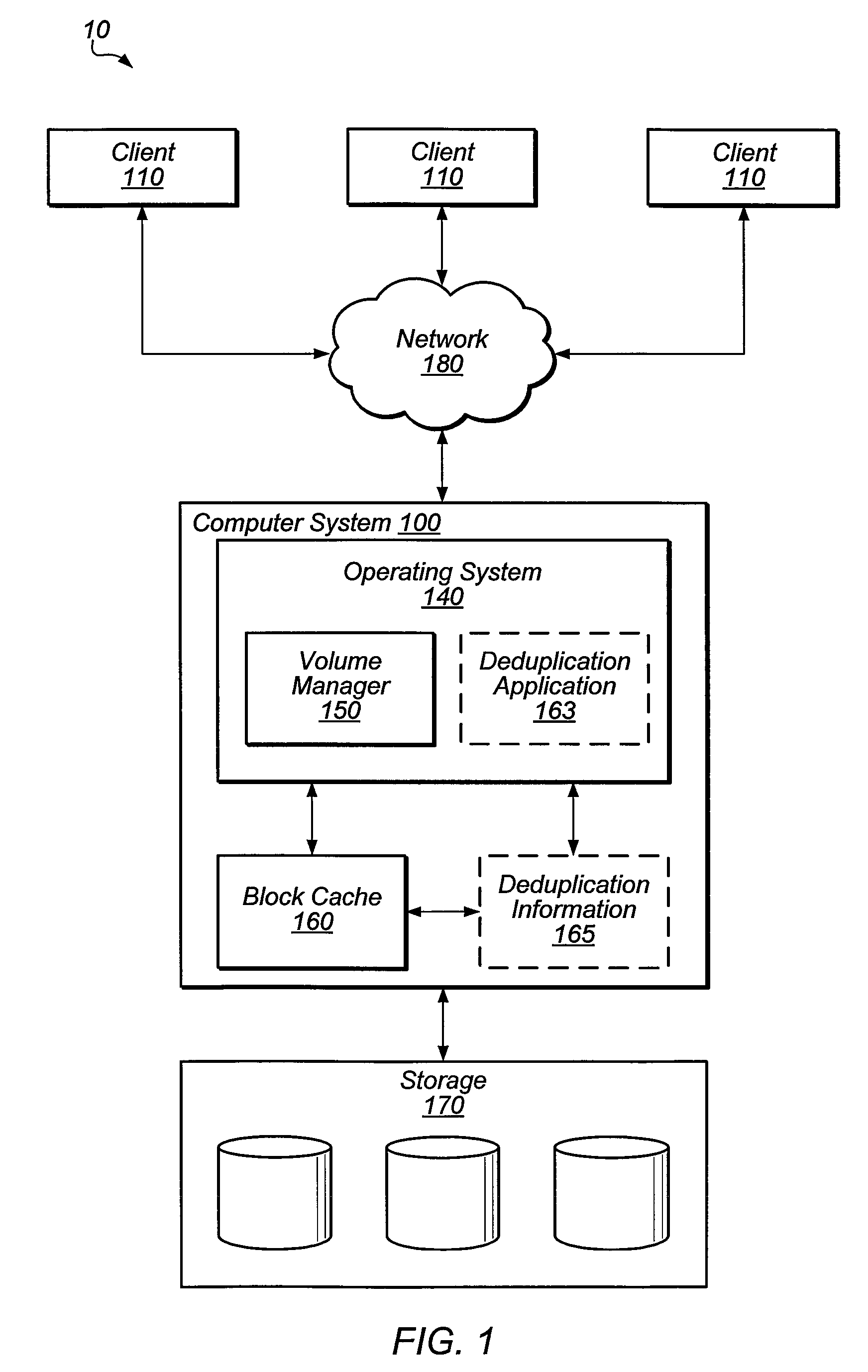

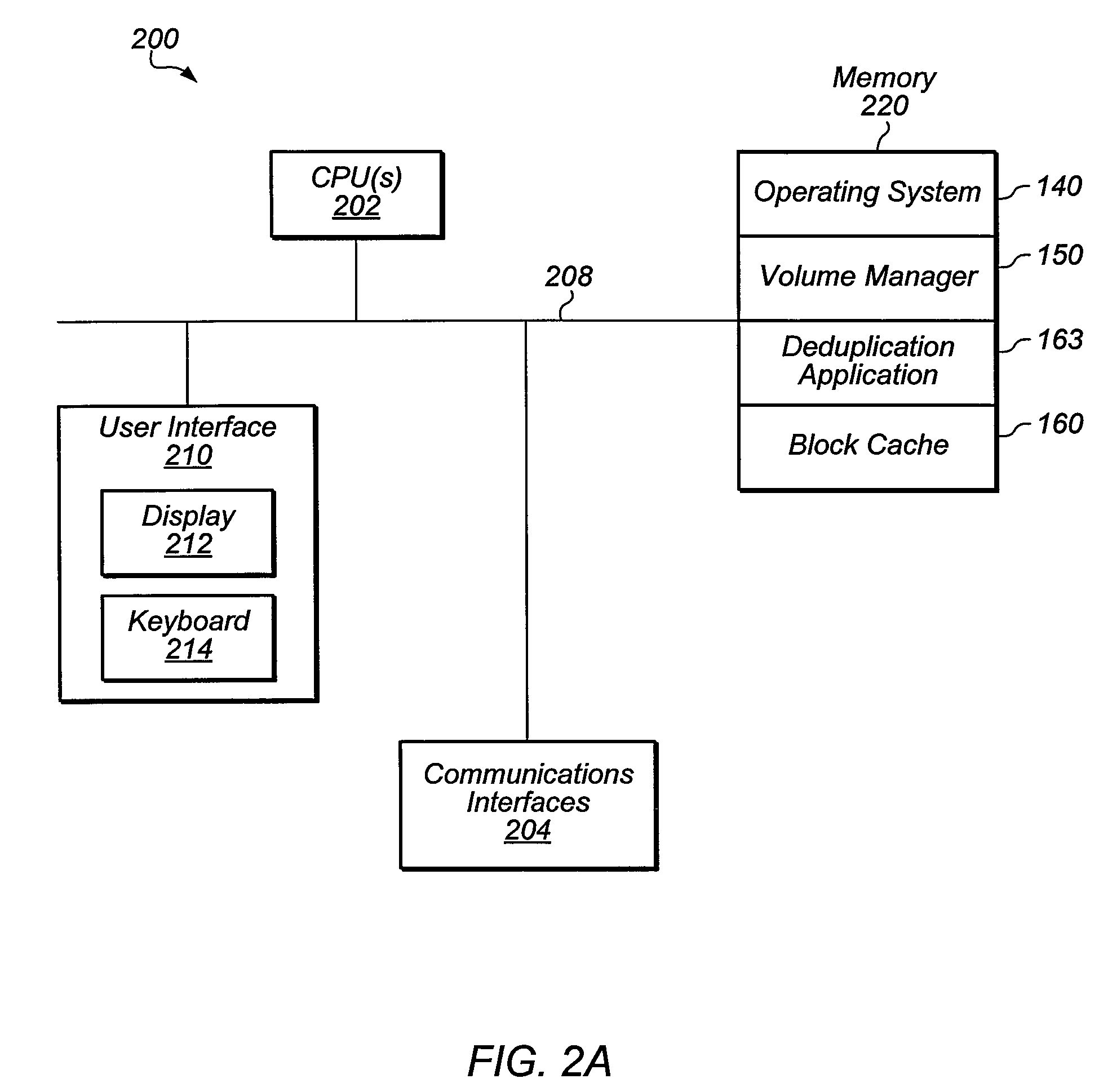

Cache management for file systems supporting shared blocks

ActiveUS8639658B1Digital data information retrievalDigital data processing detailsFile systemComputerized system

Techniques relating to data deduplication at the file system level are disclosed. A system may include a block cache configured to store data blocks indicated as being shared by multiple files. The system may be coupled to a storage configured to permanently store data for the multiple files. The computer system may receive a file request, and, upon determining that the file request includes shared data, the computer system may service the request wholly or in part using the block cache. When multiple requests including multiple file identifiers (but referring to the same underlying shared data) are received, a shared (common) file identifier may be used in looking up data for the multiple requests, reducing block cache storage, and improving block cache performance and overall system operation.

Owner:VERITAS TECH

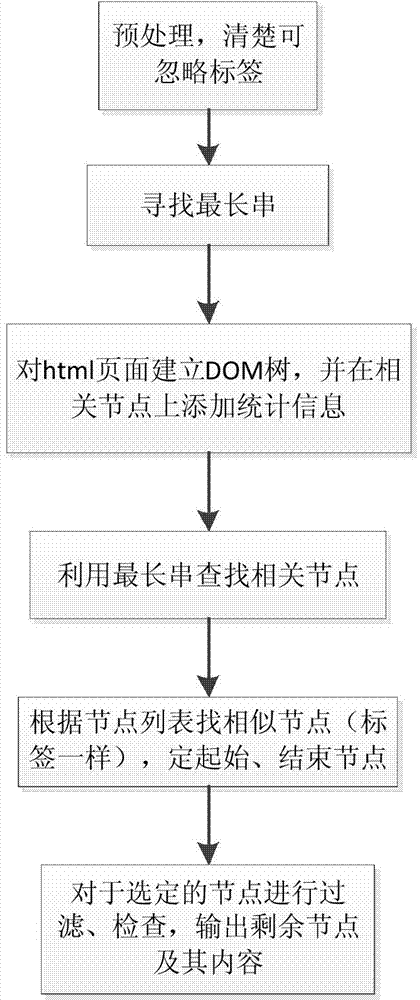

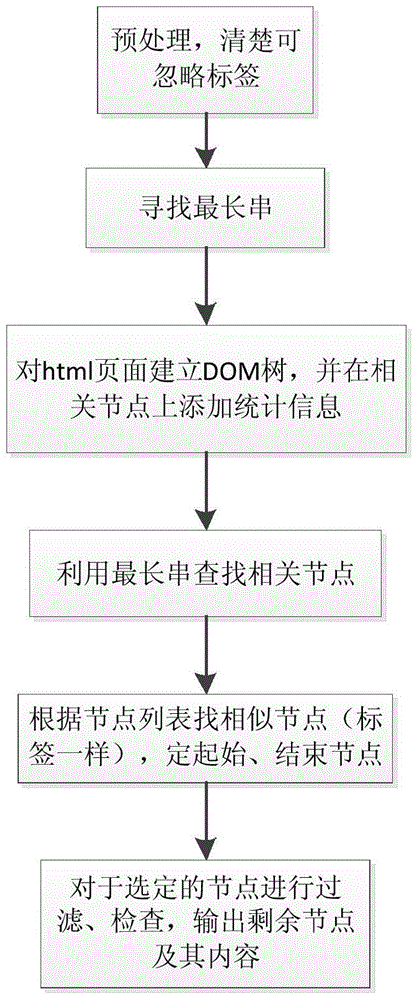

Webpage content extracting method

InactiveCN103530429AImprove work efficiencyImprove accuracyText processingSemi-structured data retrievalBlock techniquesParagraph

The invention provides a webpage content extracting method. The method comprises the following steps of I, preprocessing a webpage, II, searching for the longest series in the webpage, III, establishing a DOM tree and searching for the nodes corresponding to the longest series according to the DOM tree, IV, determining a beginning node and a finishing node according to labels of the nodes corresponding to the longest series, V, checking and filtering the beginning node and the finishing node, and VI, outputting text in the filtered beginning node and text in the filtered finishing node. The method overcomes the defect of a module or blocking technique in news content extraction application, searches for seed paragraphs based on the longest series and improves webpage content extracting work efficiency and accuracy.

Owner:北京中搜云商网络技术有限公司

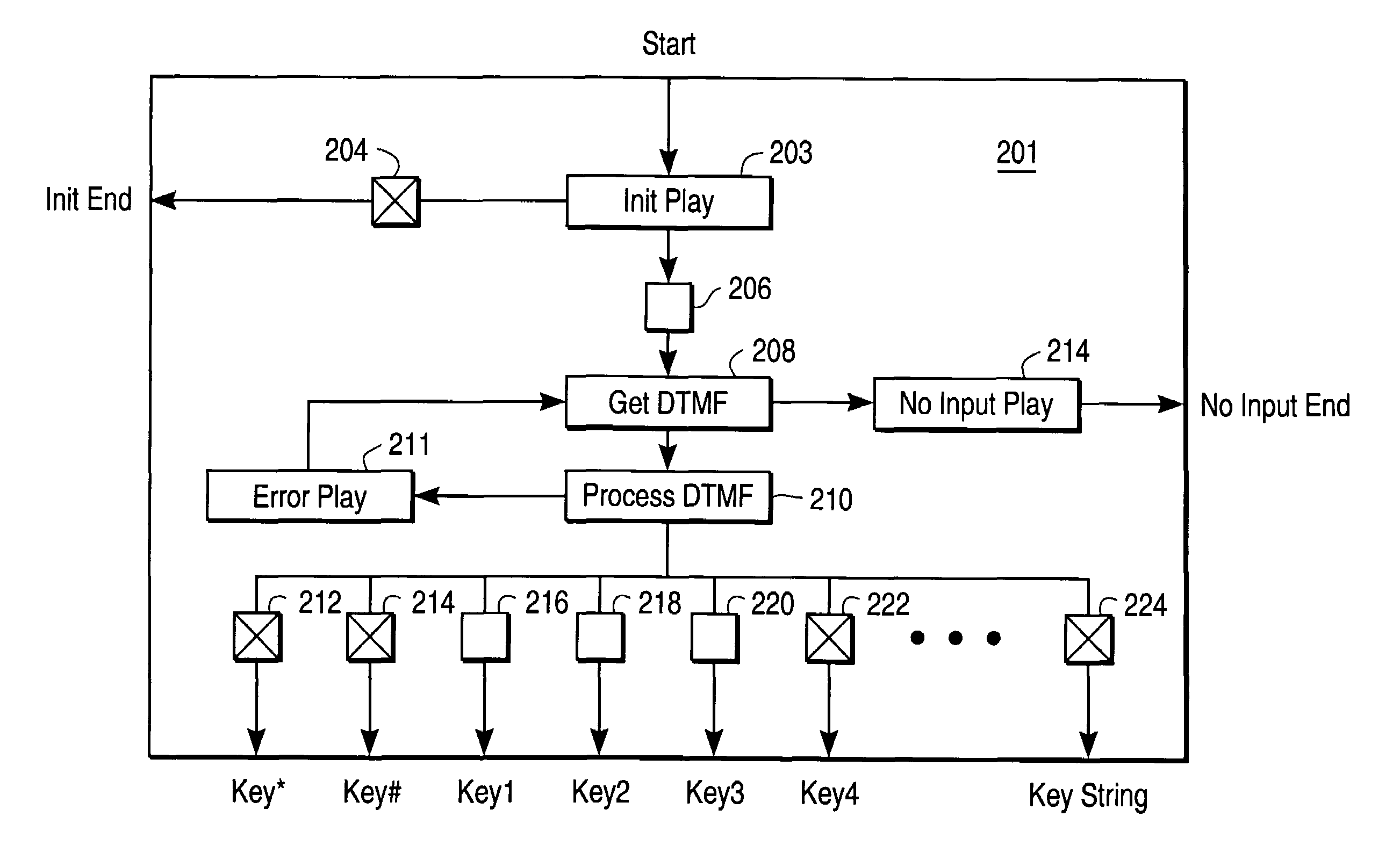

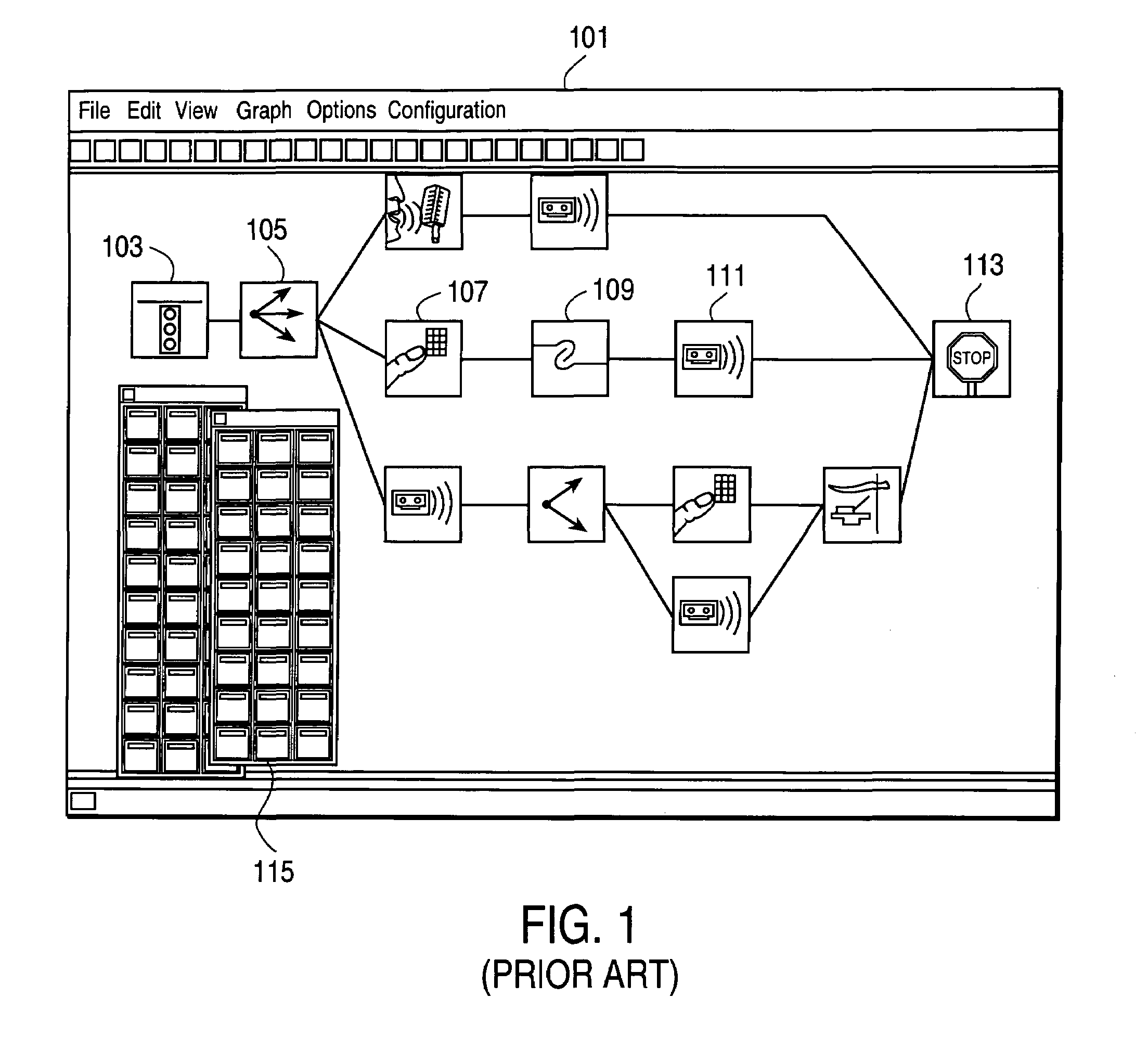

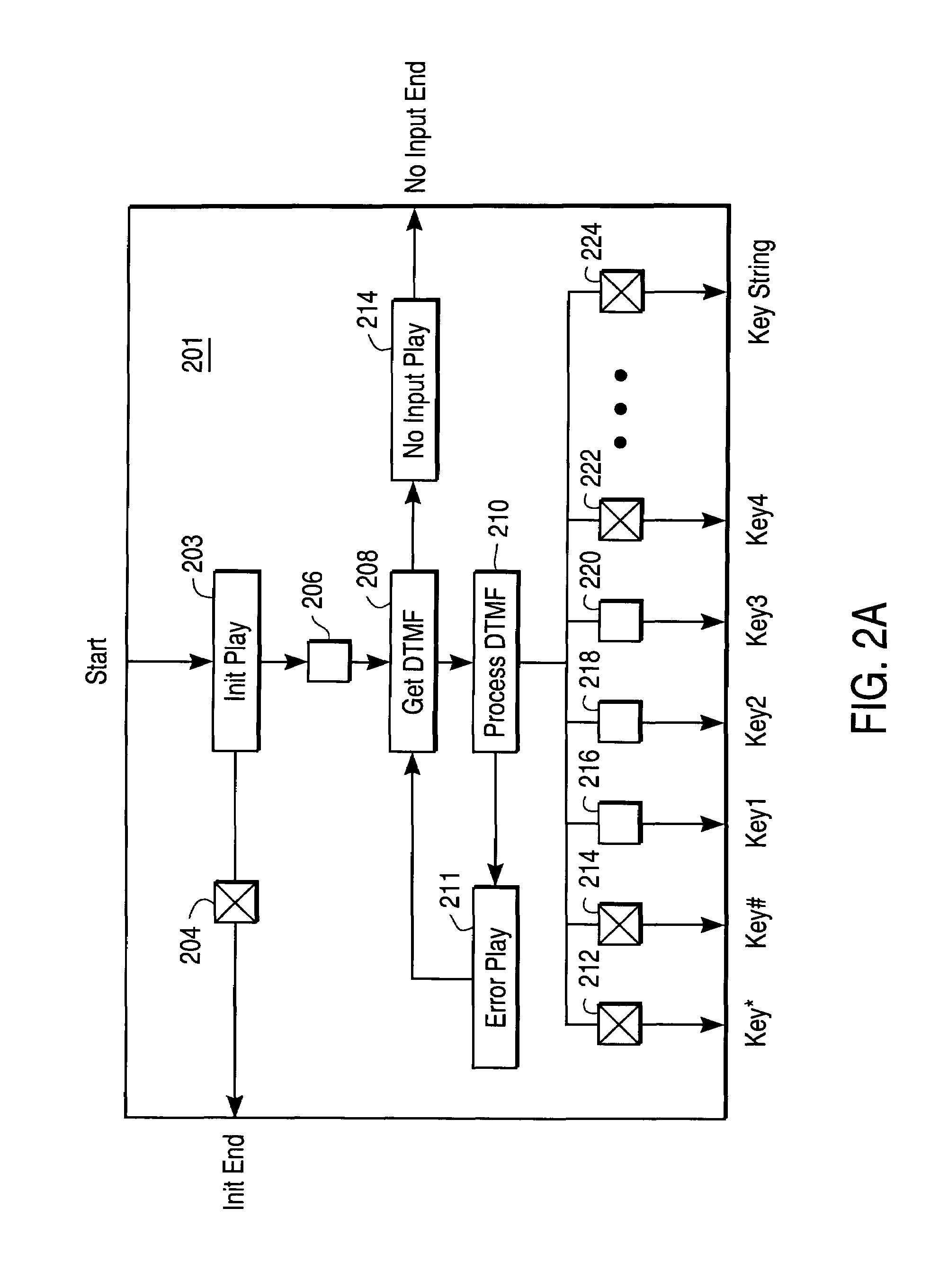

Interactive voice response systems with general-purpose blocks

InactiveUS7031440B1Developed quickly and easilyEasy maintenanceAutomatic exchangesGeneral purposeInteractive voice response system

Techniques for generating interactive voice response systems are provided. Multiple interconnected general-purpose blocks can be configured for a specific IVR application. Each general purpose block can include prompts and logic for receiving input. By utilizing general-purpose blocks, complex IVR applications can be quickly and efficiently generated. Additionally, IVR applications can be upgraded and maintained during run-time.

Owner:UNIFY INC

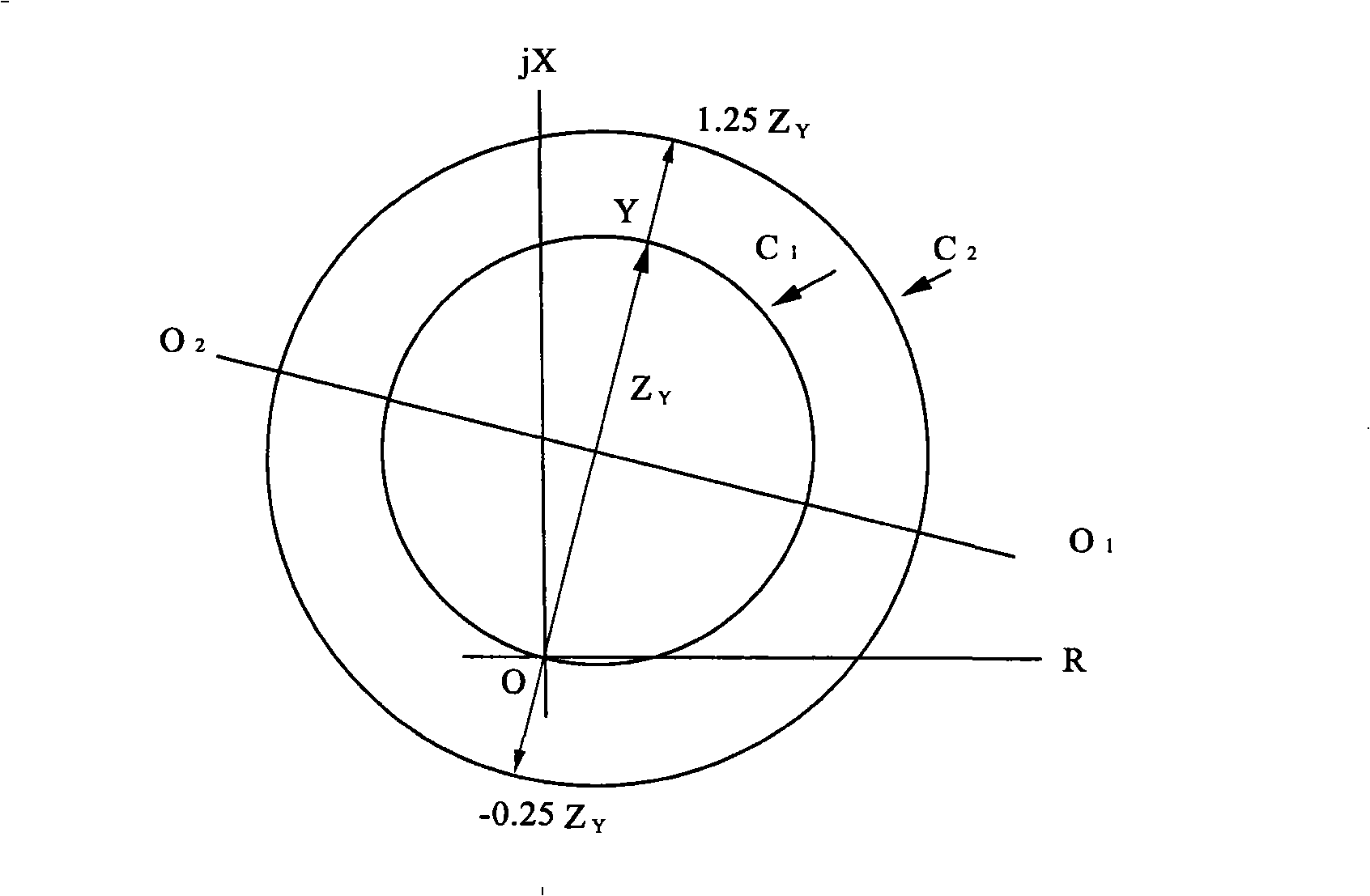

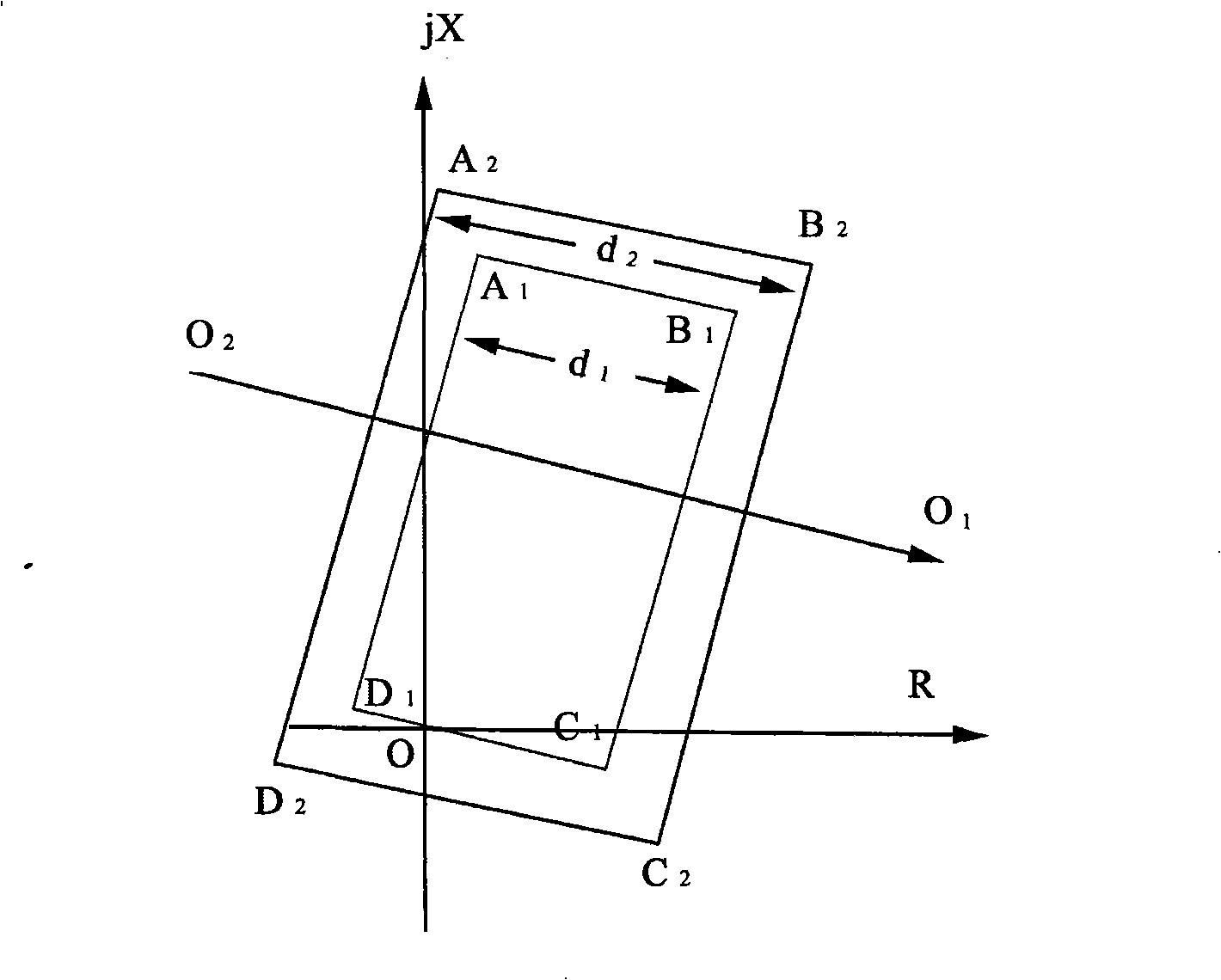

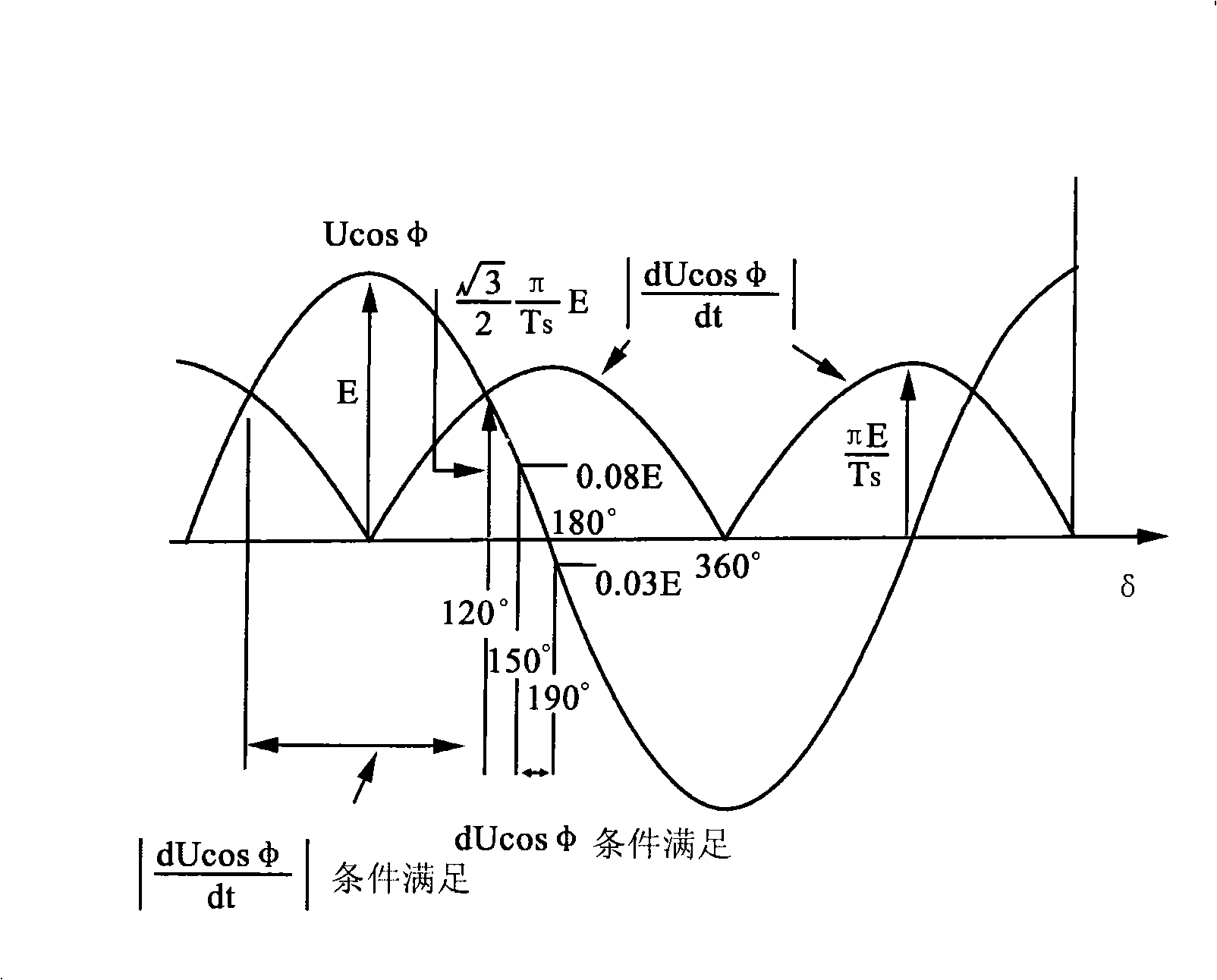

New method for distance protection surge lock of high voltage output line

ActiveCN101267109ANo malfunctionAvoid blackoutsEmergency protective circuit arrangementsFault locationPeriodic oscillationHigh pressure

The present invention provides a blocking method of distance protection swing of a high voltage transmission line, the swing blocking technique in the high voltage transmission line distance protection has always been one of the focus discusses. The technical scheme of the invention has two swing blocking methods having different principles, automatically selecting one swing blocking method according the length of the protection line. When the protection judgement is a short line, periodic oscillation change rate and the position of the apparent impedance are real-time detected by a stackable counter, the dwell is relatively adjusted and the relieved, the method is not only applied to the great round covering the small round type operation characteristics, but also applied to the great quadrilateral covering the small quadrilateral type operation characteristics; when the protection judgement is a long transmission line, the swing blocking pattern fpr detecting Ucos fai and its change rate is utilized. Two patterns is automatically switched by the command set in a microcomputer software program, according to the size of the setting impedance.

Owner:北京衡天北斗科技有限公司

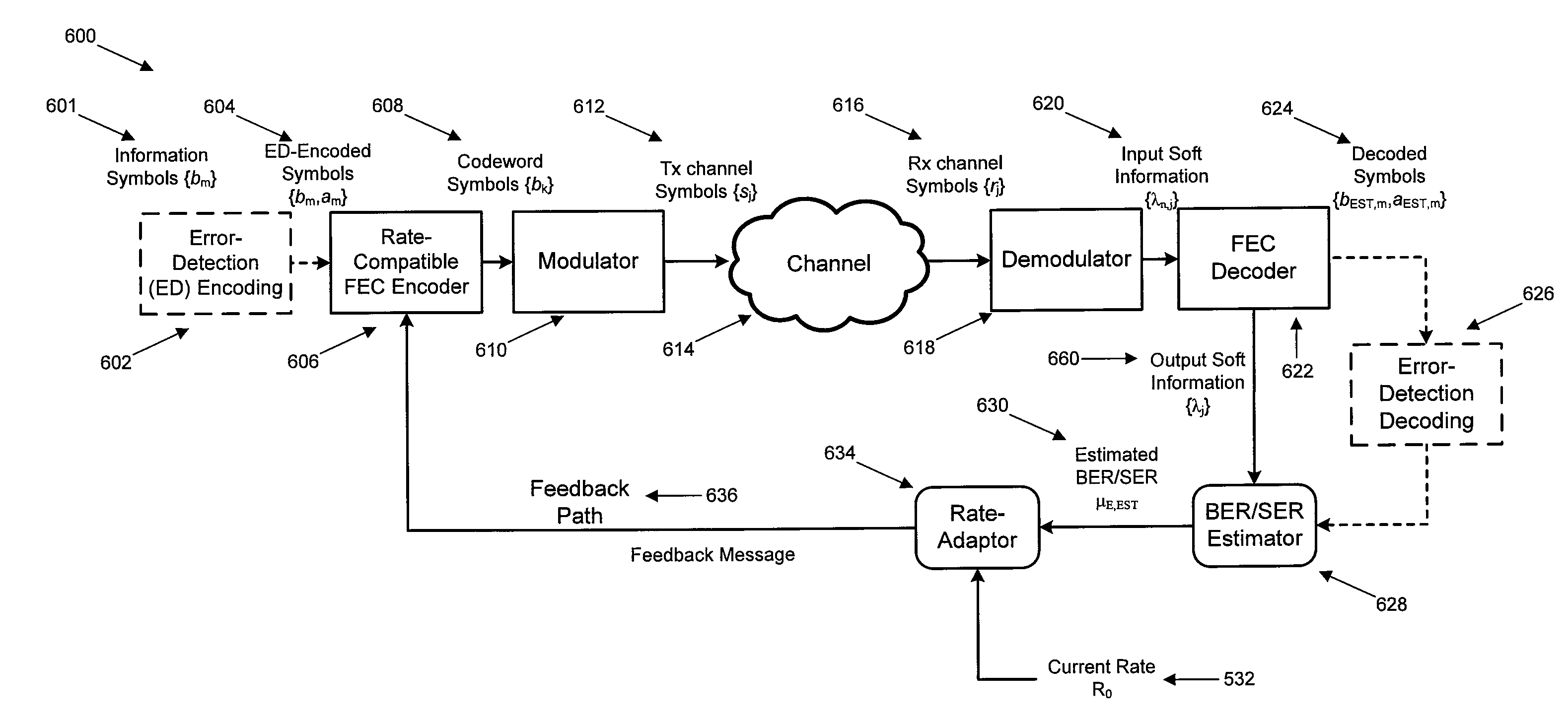

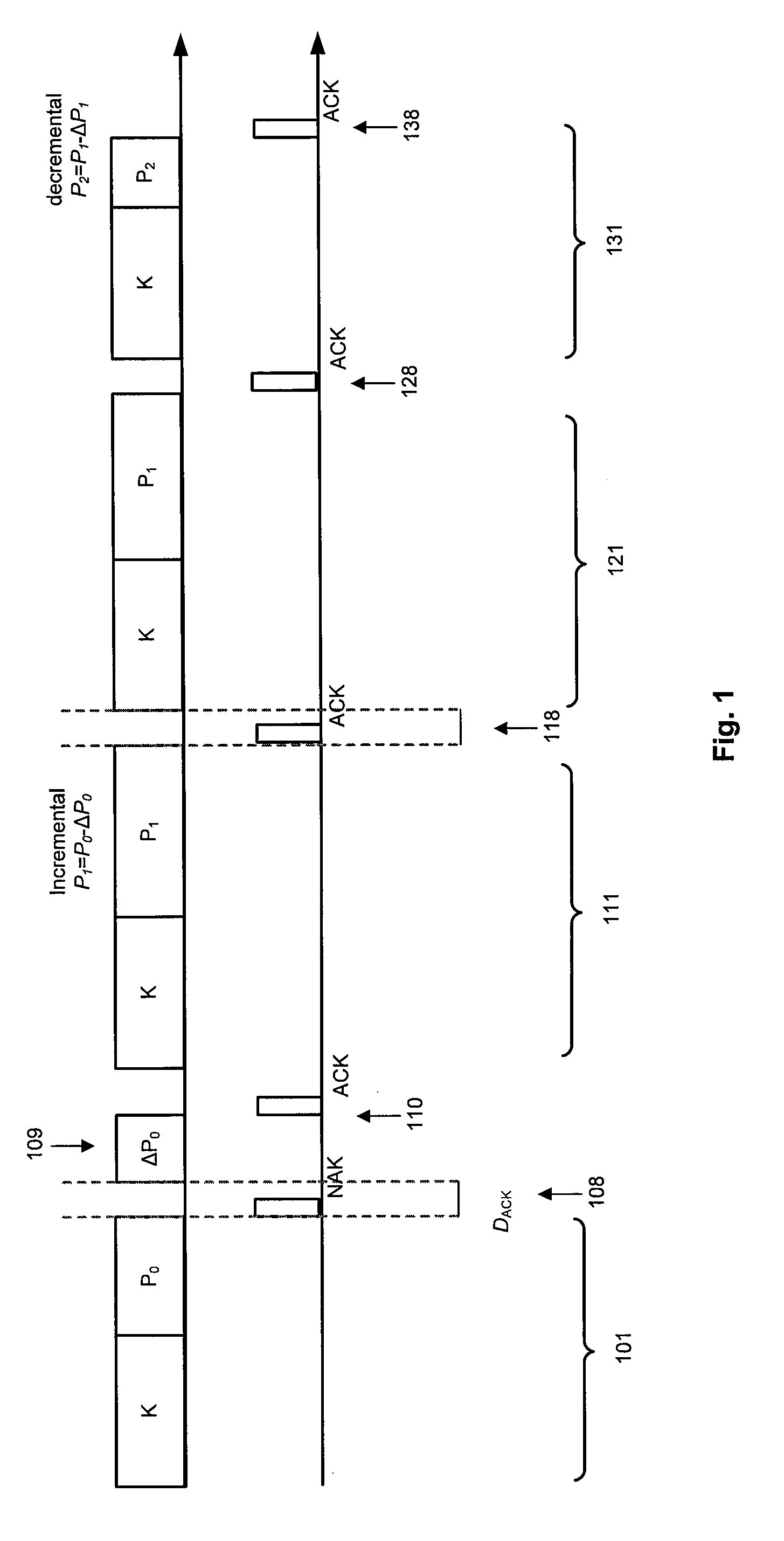

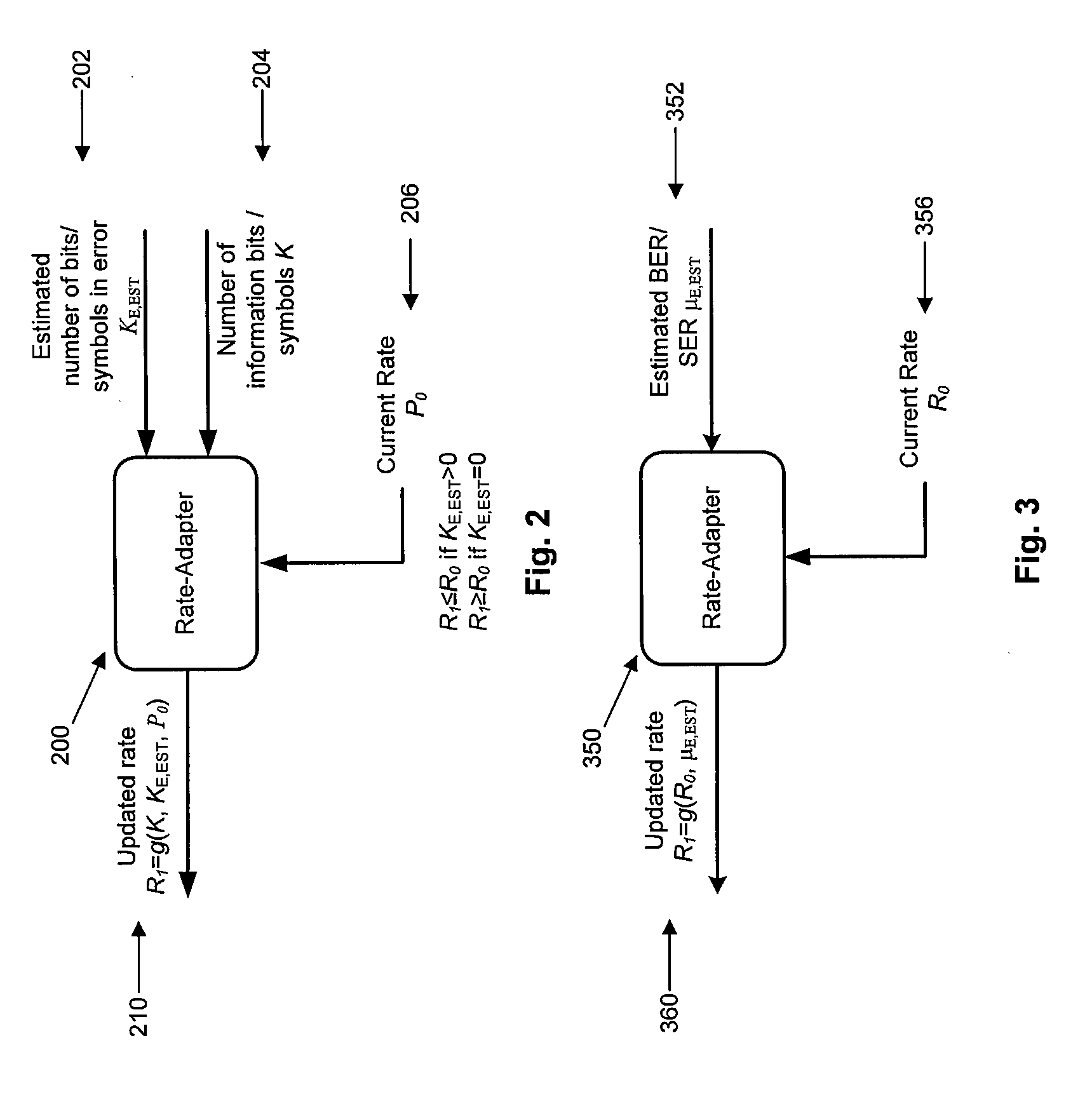

Error rate estimation/application to code-rate adaption

The disclosure proposes bit-error-rate (BER) and symbol-error-rate (SER) estimation techniques and its application to incremental-redundancy and rate-adaptation for modern-coded hybrid-ARQ systems. In particular, BER / SER estimators are proposed based on iterative refinement of mixture-density modeling of the bit / symbol decision metrics. For hybrid-ARQ systems, rate-adaptation functions are proposed based on BER / SER estimators for failed transmissions. Methods are disclosed for code-rate selection based on successfully decoded blocks as well as incremental parity size selection for retransmission of failed blocks Techniques disclosed here apply to forward-error-correction codes employed for digital data communication systems.

Owner:TRELLIS WARE TECH

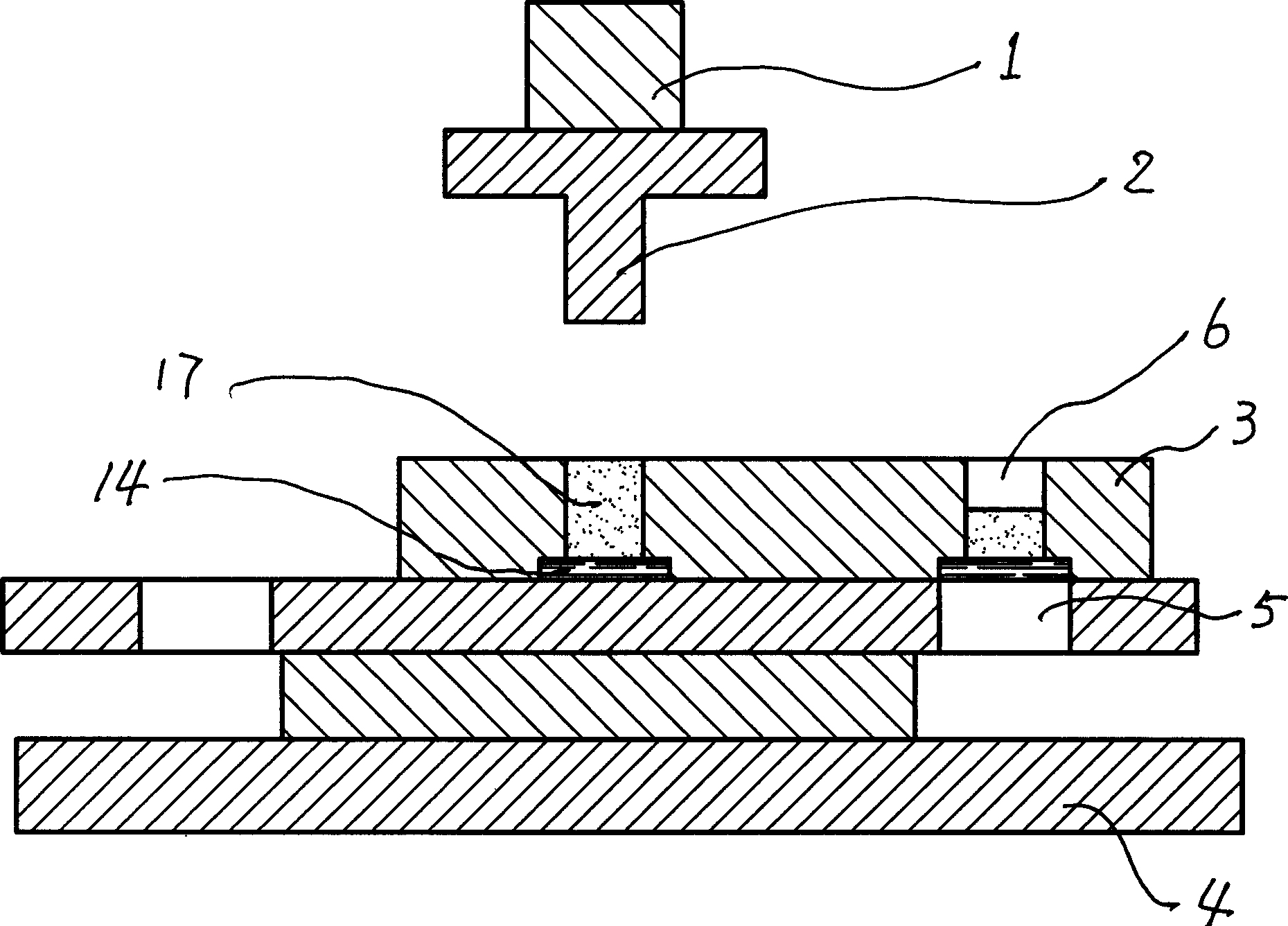

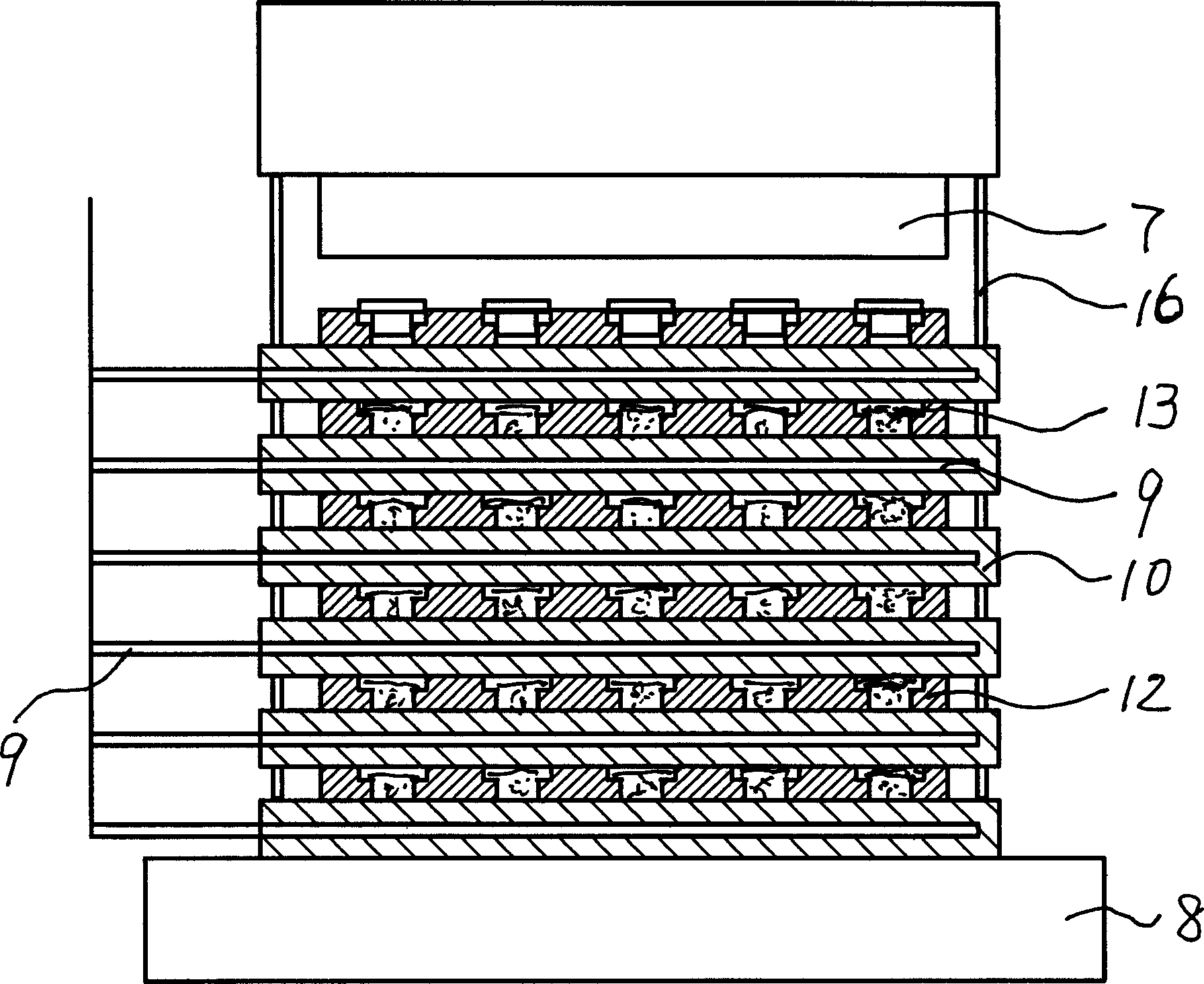

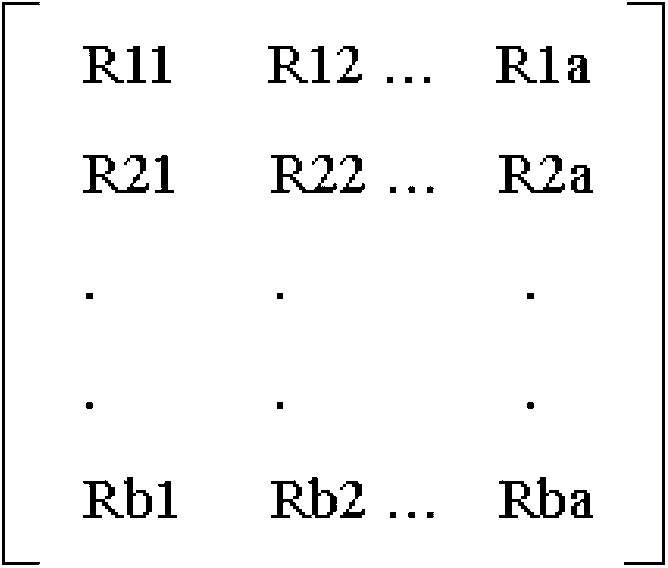

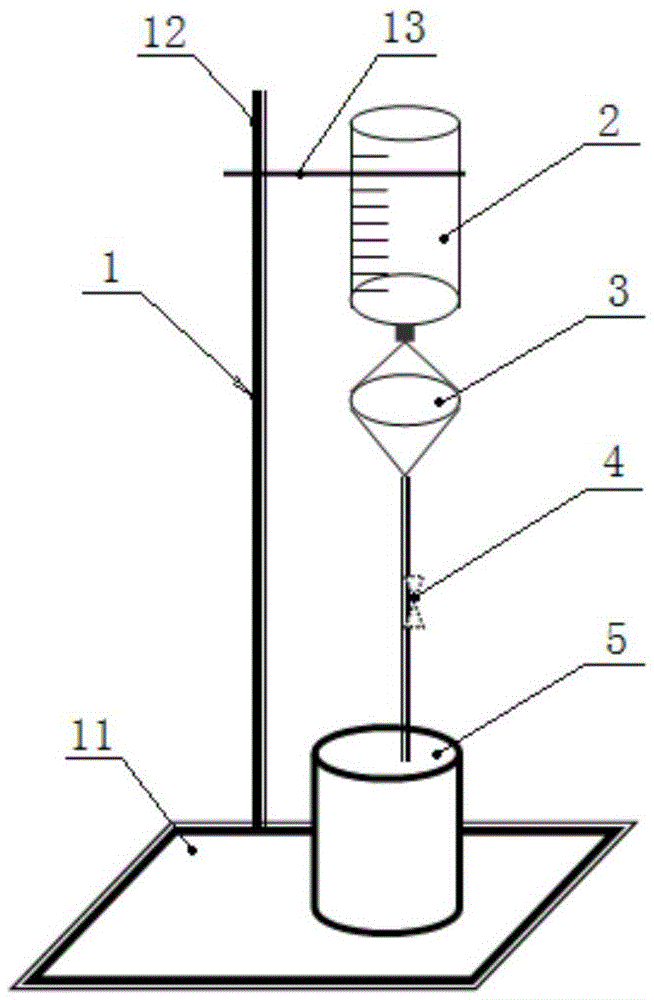

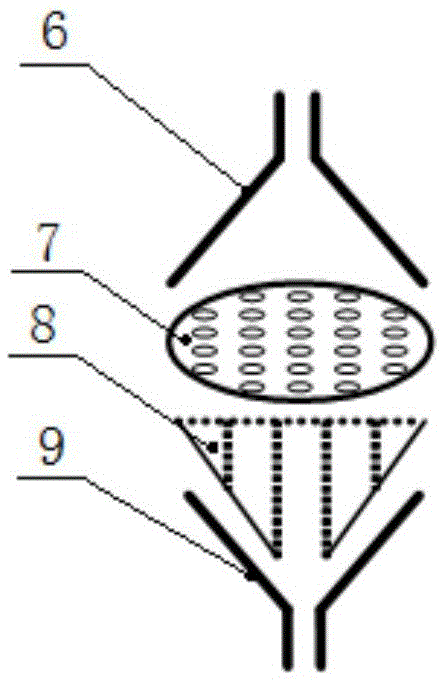

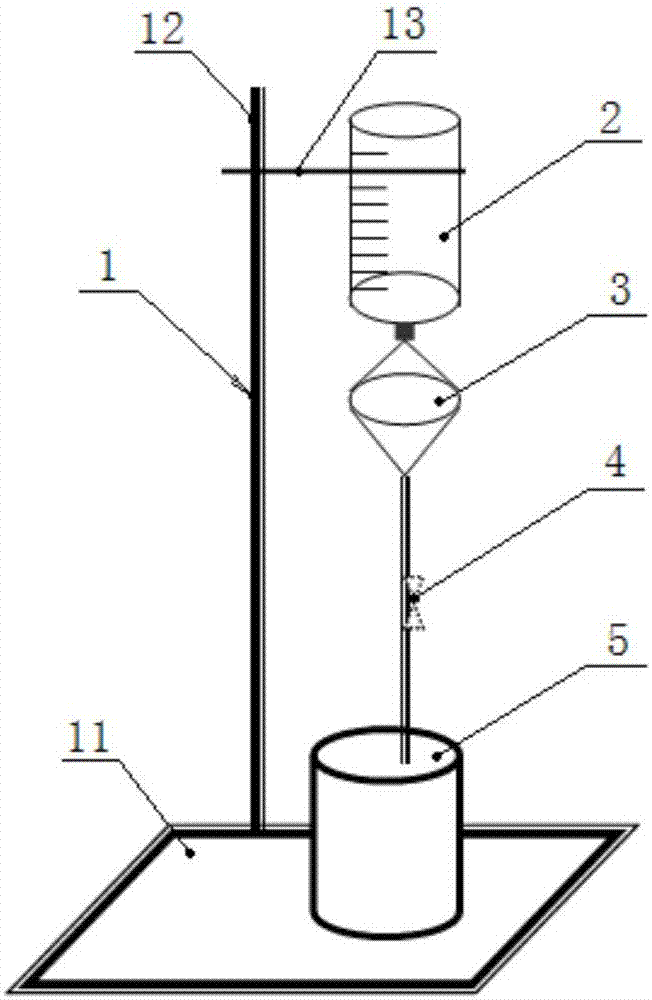

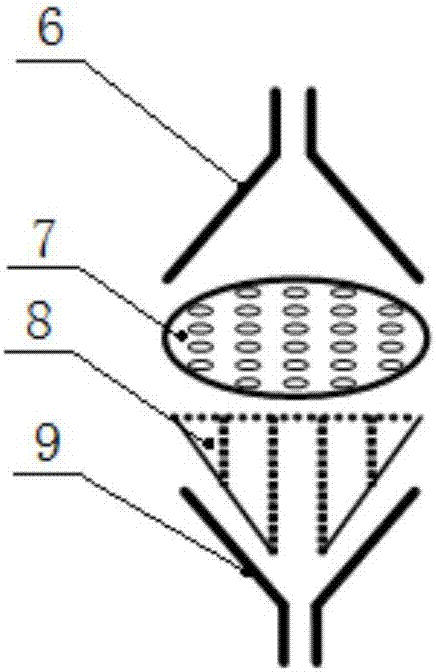

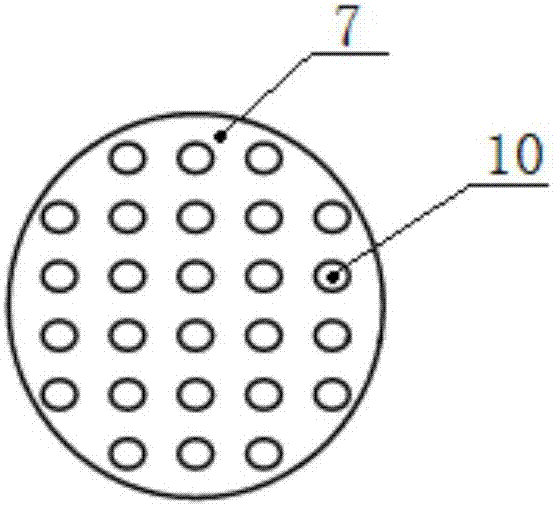

Preparation process for disk type brake lining and dedicated apparatus therefor

InactiveCN1828082AEven heat transfer insideReduce temperature gradientFriction liningStress distributionBrake lining

The invention relates to a preparing method and special device of disc brake block, belonging to the brake block technique. The inventive method comprises: preparing steel back; preparing liner material; cold compressing molding; heat compressing solidifying and hot treatment. The invention adds cold compressing molding of brake block, therefore, the brake block has uniform hot stress distribution to avoid the defects of expansion and chap, with lower cost and high producing efficiency.

Owner:河北星月制动元件有限公司

Output reporting techniques for hard intellectual property blocks

Techniques for reducing the frequency of an output signal from a hard intellectual property (HIP) block on an integrated circuit are provided. By reducing the frequency of the output signal, circuit blocks in the integrated circuit that operate at a lower frequency than the HIP block are able to capture the output signal. A plurality of serially coupled flip-flops store values of an HIP output signal during each period of the output signal. Logic circuitry then generates a lower frequency HIP output signal in response to the values stored in the flip-flops. Also, a flip-flop can generate a heartbeat signal that is used to determine whether a signal within an HIP block is operating properly.

Owner:ALTERA CORP

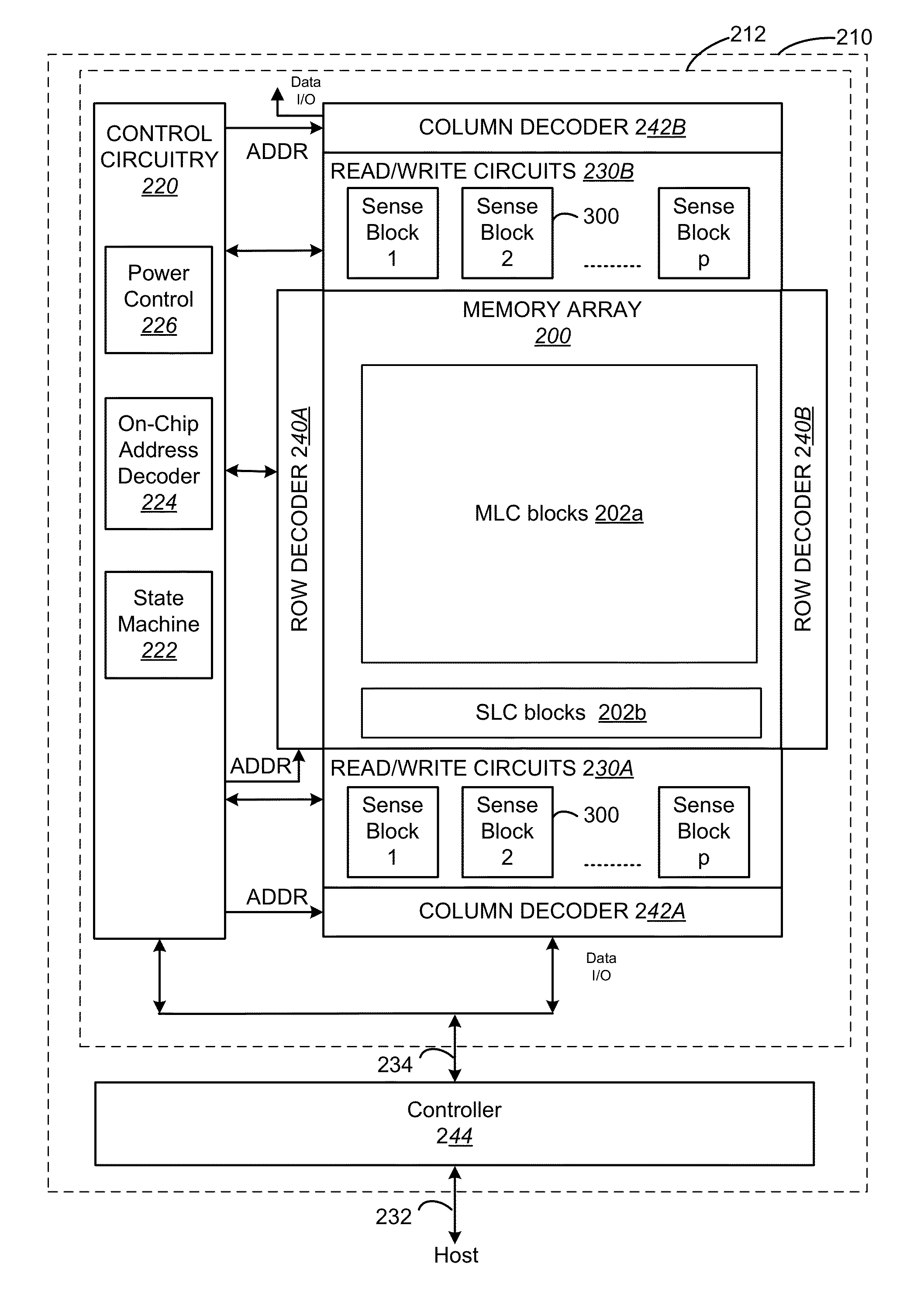

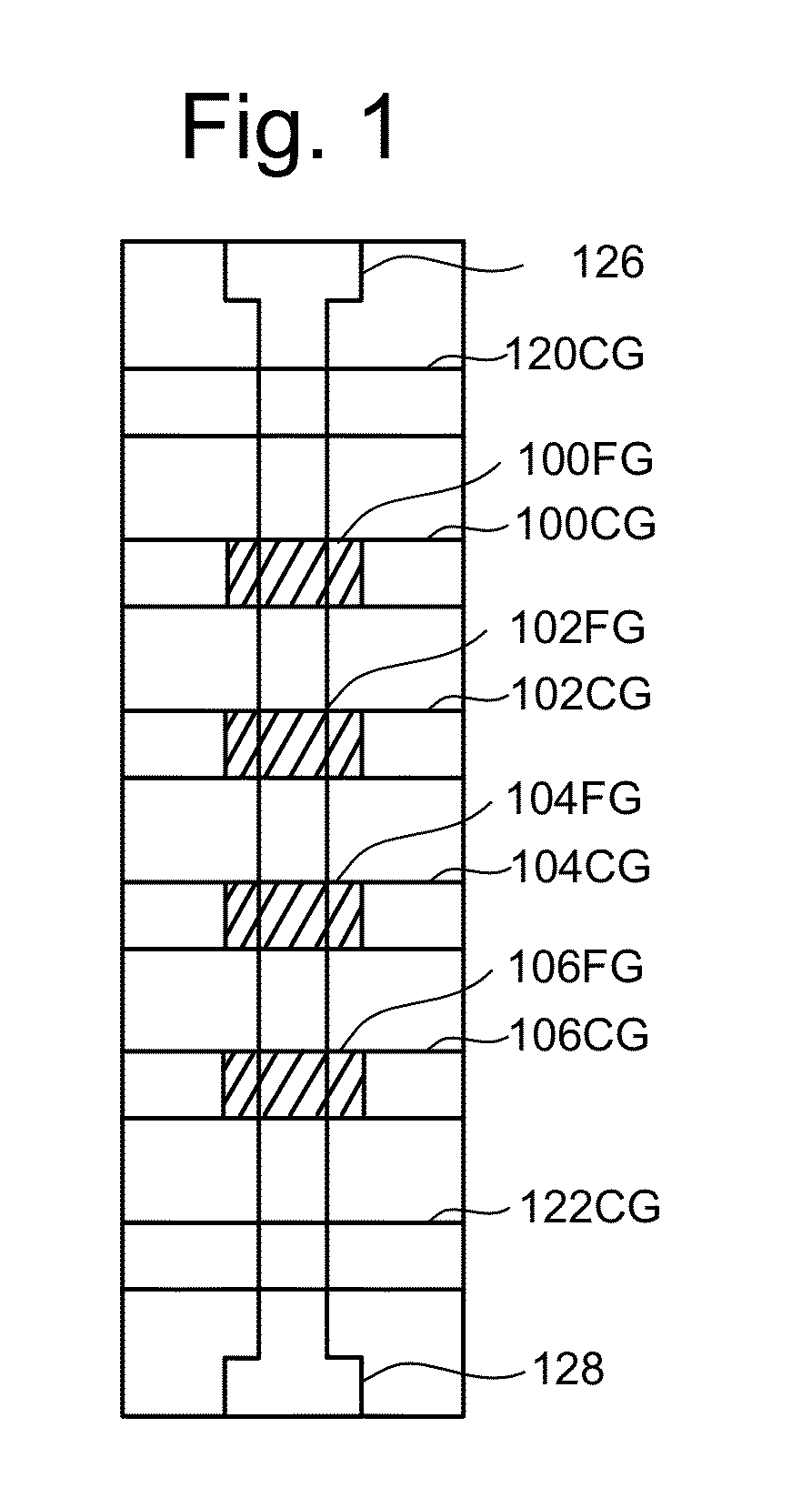

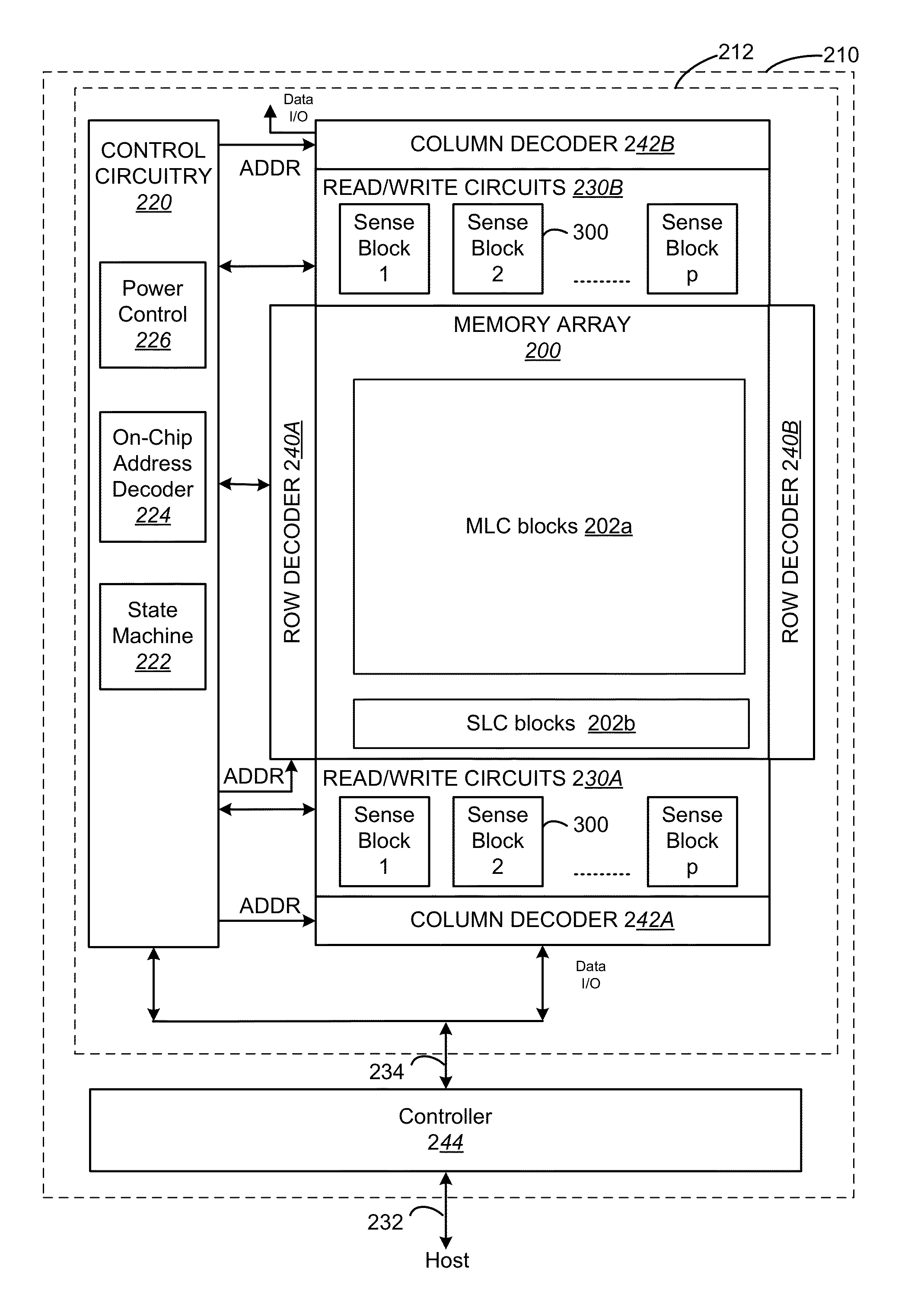

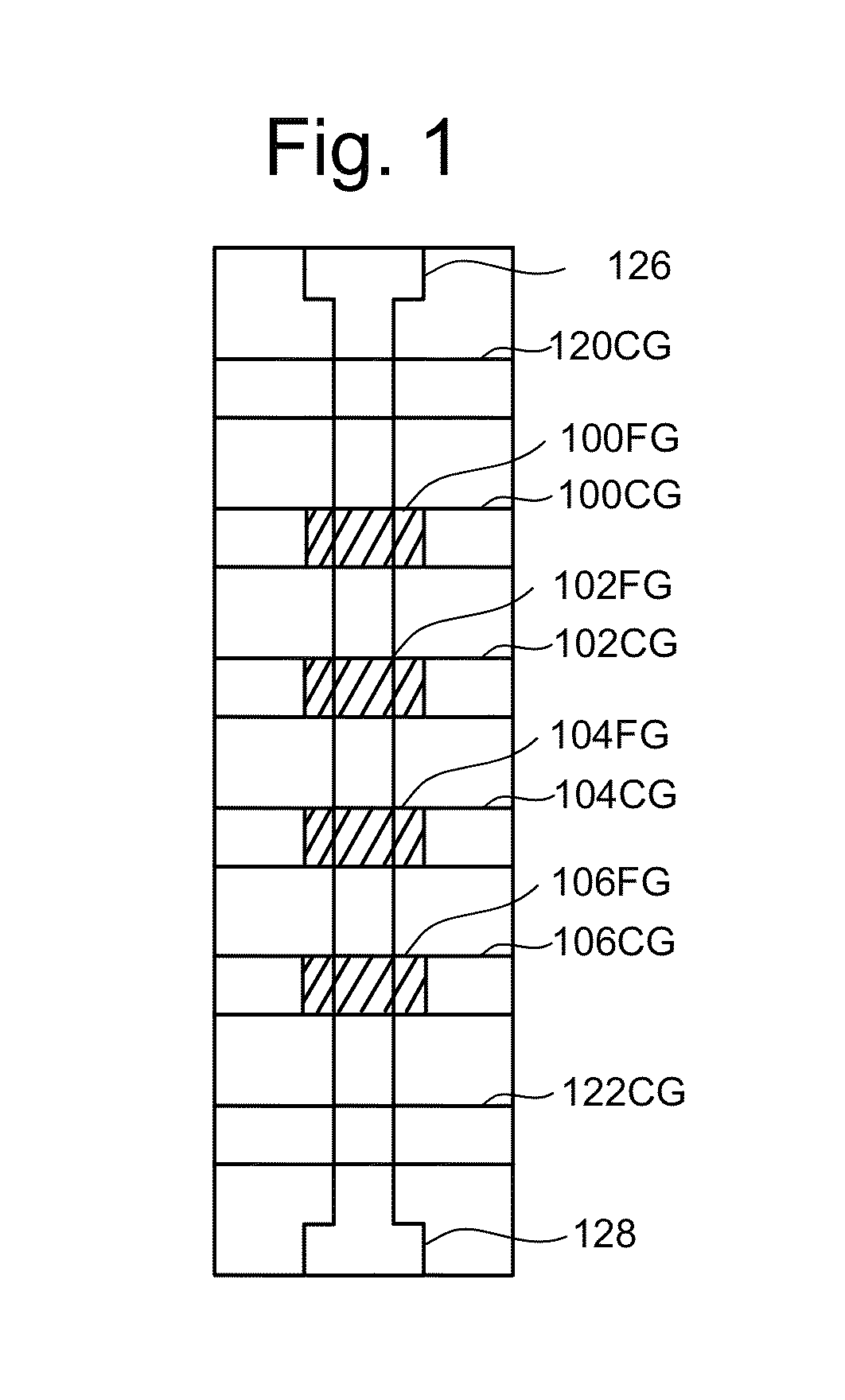

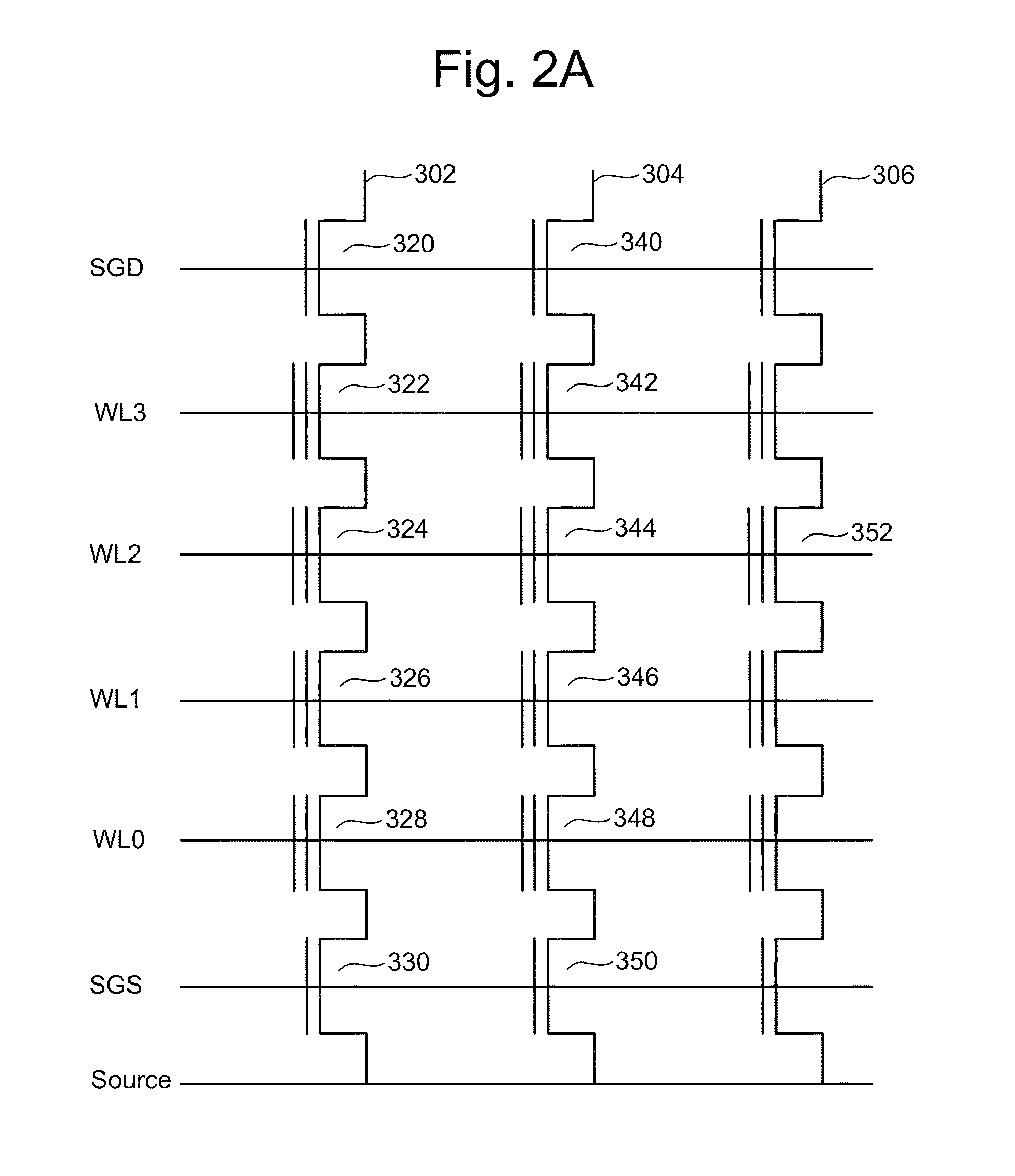

Single-level cell endurance improvement with pre-defined blocks

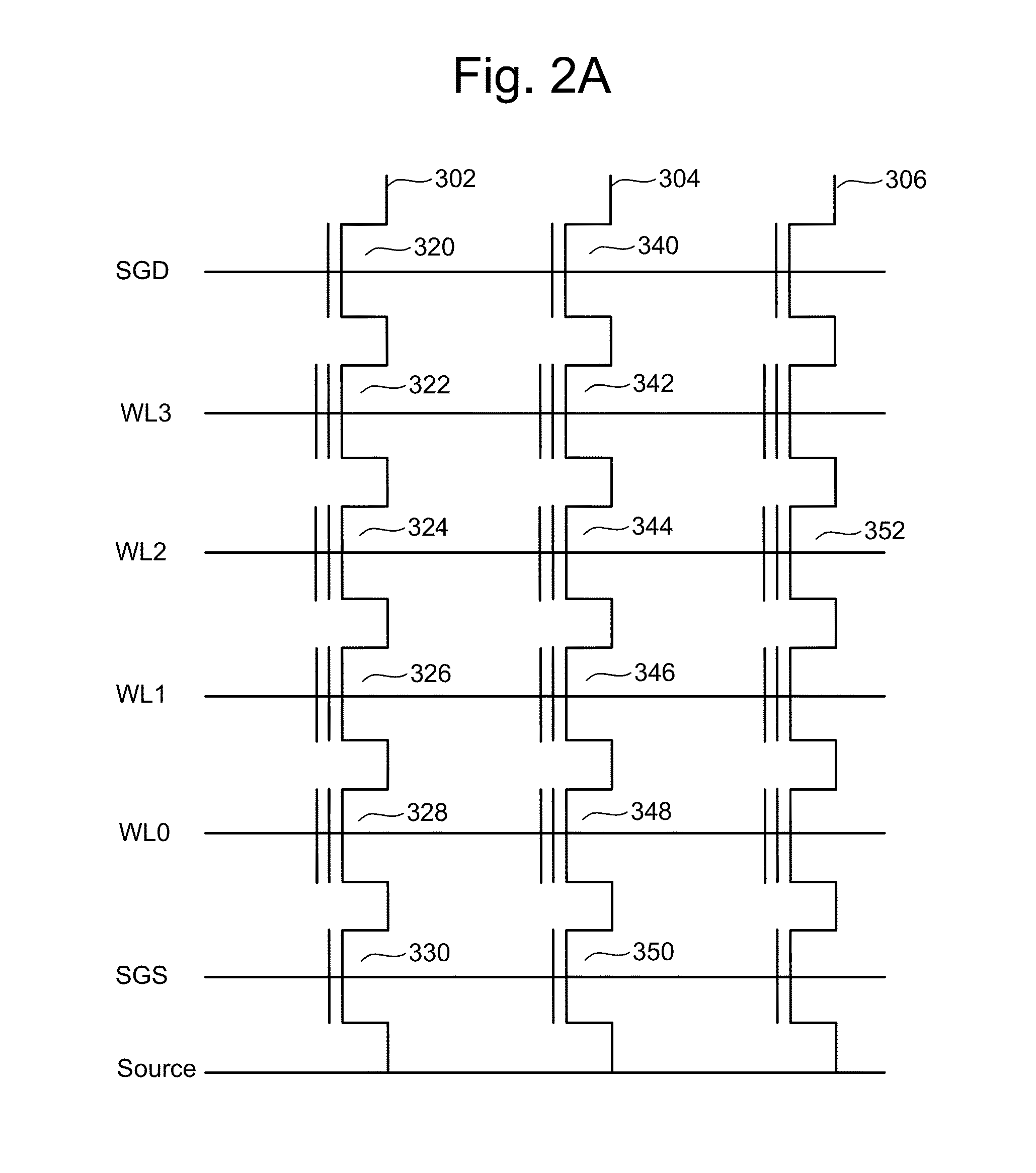

ActiveUS20140126286A1Read-only memoriesSemiconductor/solid-state device manufacturingComputer architectureComputer module

Techniques are disclosed for SLC blocks having different characteristics than MLC blocks such that SLC blocks will have high endurance and MLC blocks will have high reliability. A thinner tunnel oxide may be used for memory cells in SLC blocks than for memory cells in MLC blocks. A thinner tunnel oxide in SLC blocks may allow a lower program voltage to be used, which may improve endurance. A thicker tunnel oxide in MLC blocks may improve data retention. A thinner IPD may be used for memory cells in SLC blocks than for memory cells in MLC blocks. A thinner IPD may provide a higher coupling ratio, which may allow a lower program voltage. A lower program voltage in SLC blocks can improve endurance. A thicker IPD in MLC blocks can prevent or reduce read disturb. SLC blocks may have a different number of data word lines than MLC blocks.

Owner:SANDISK TECH LLC

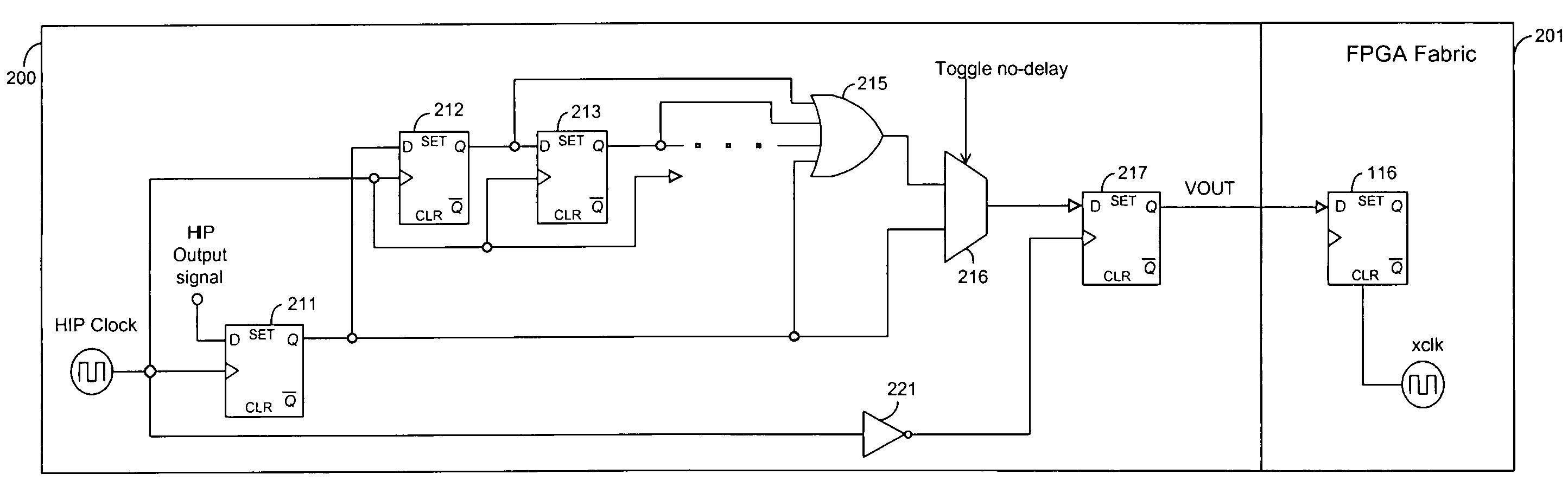

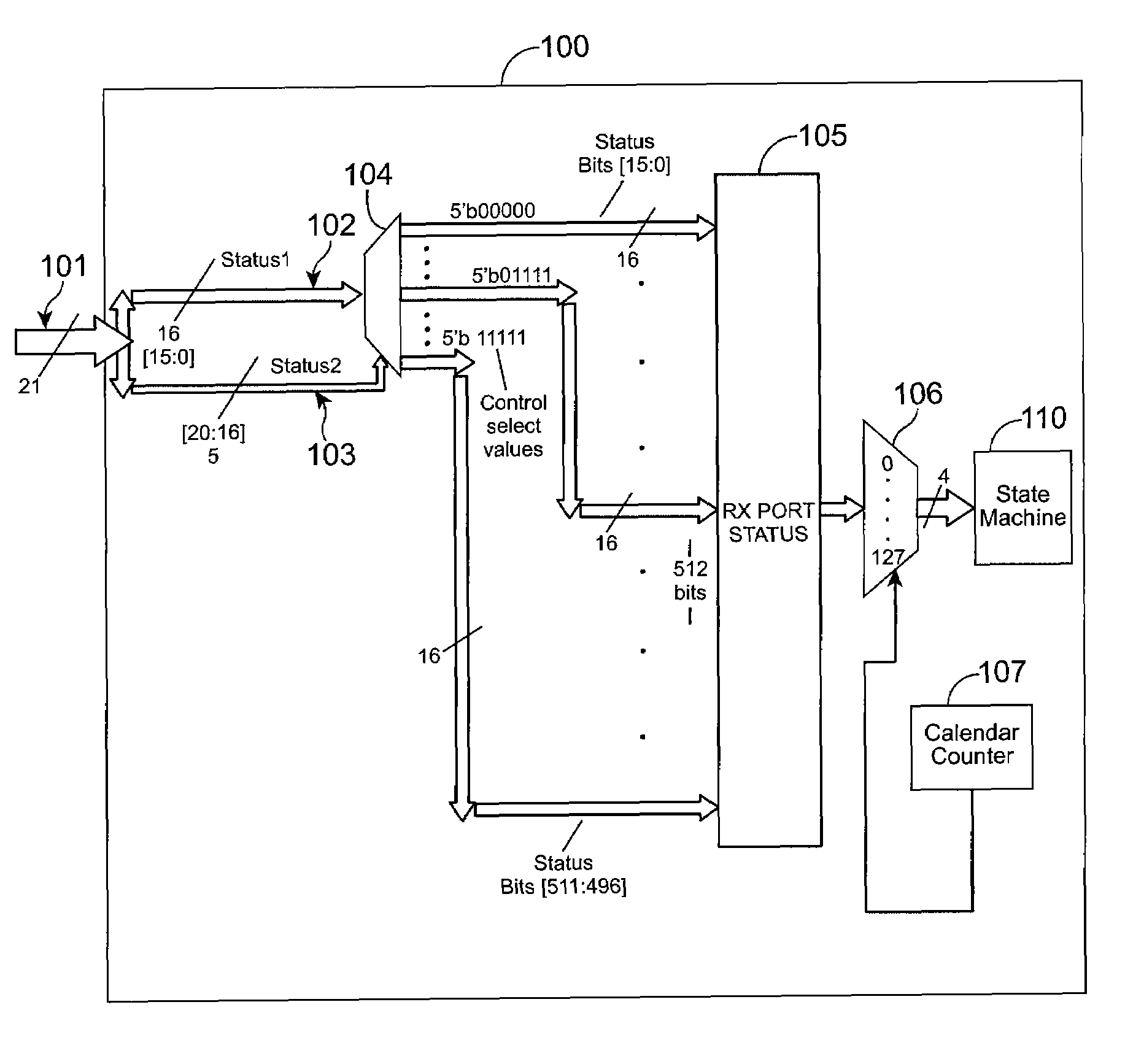

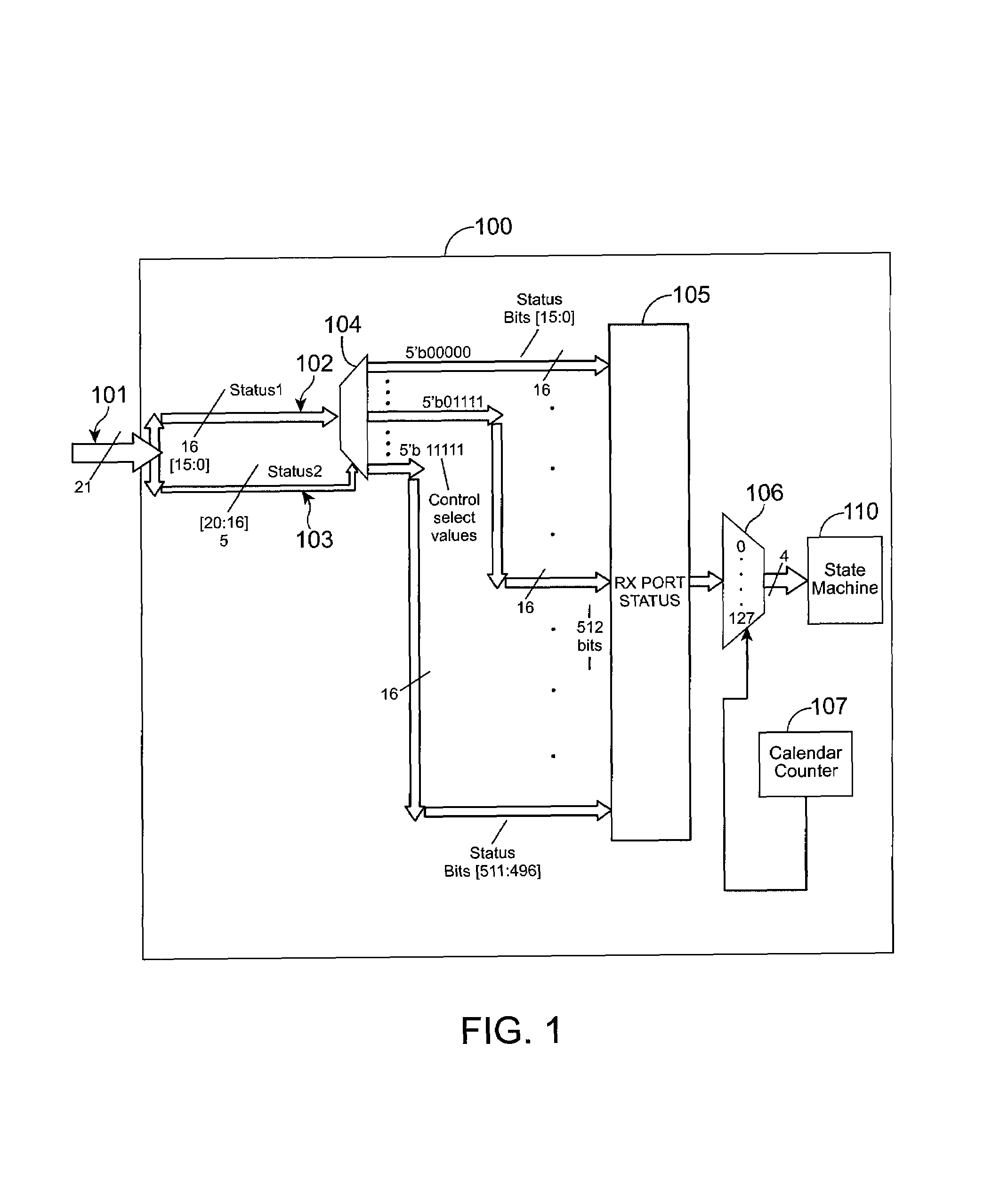

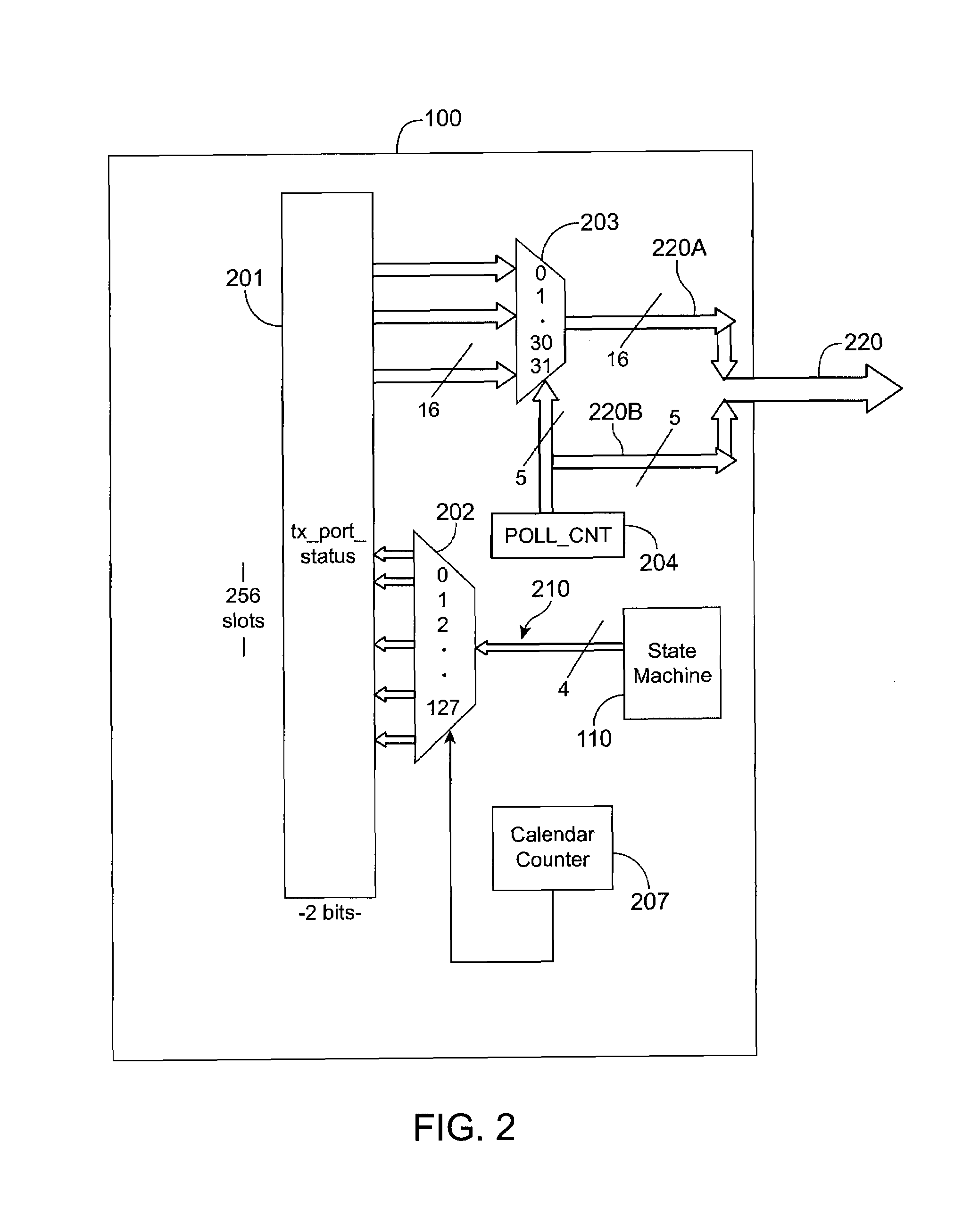

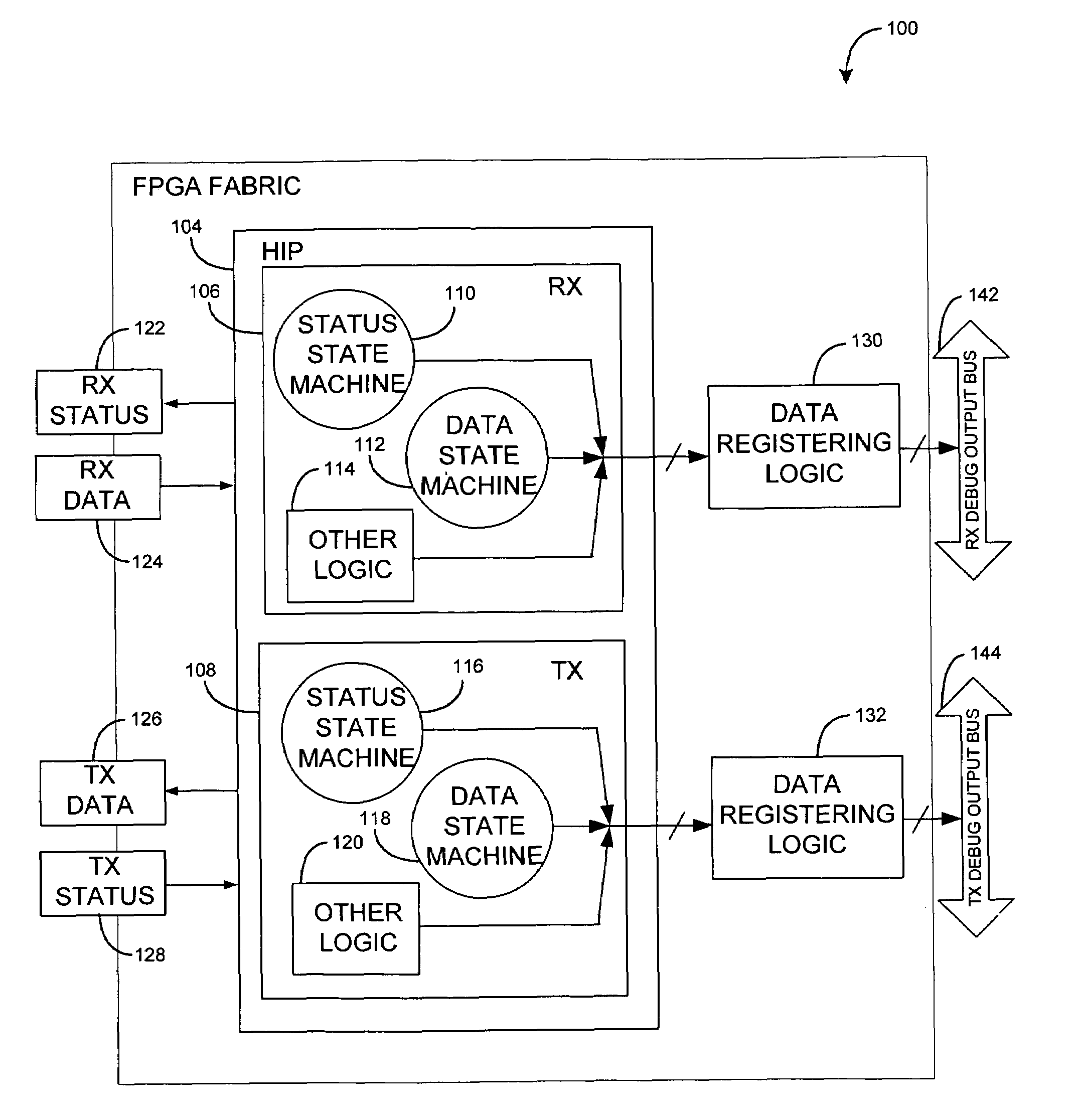

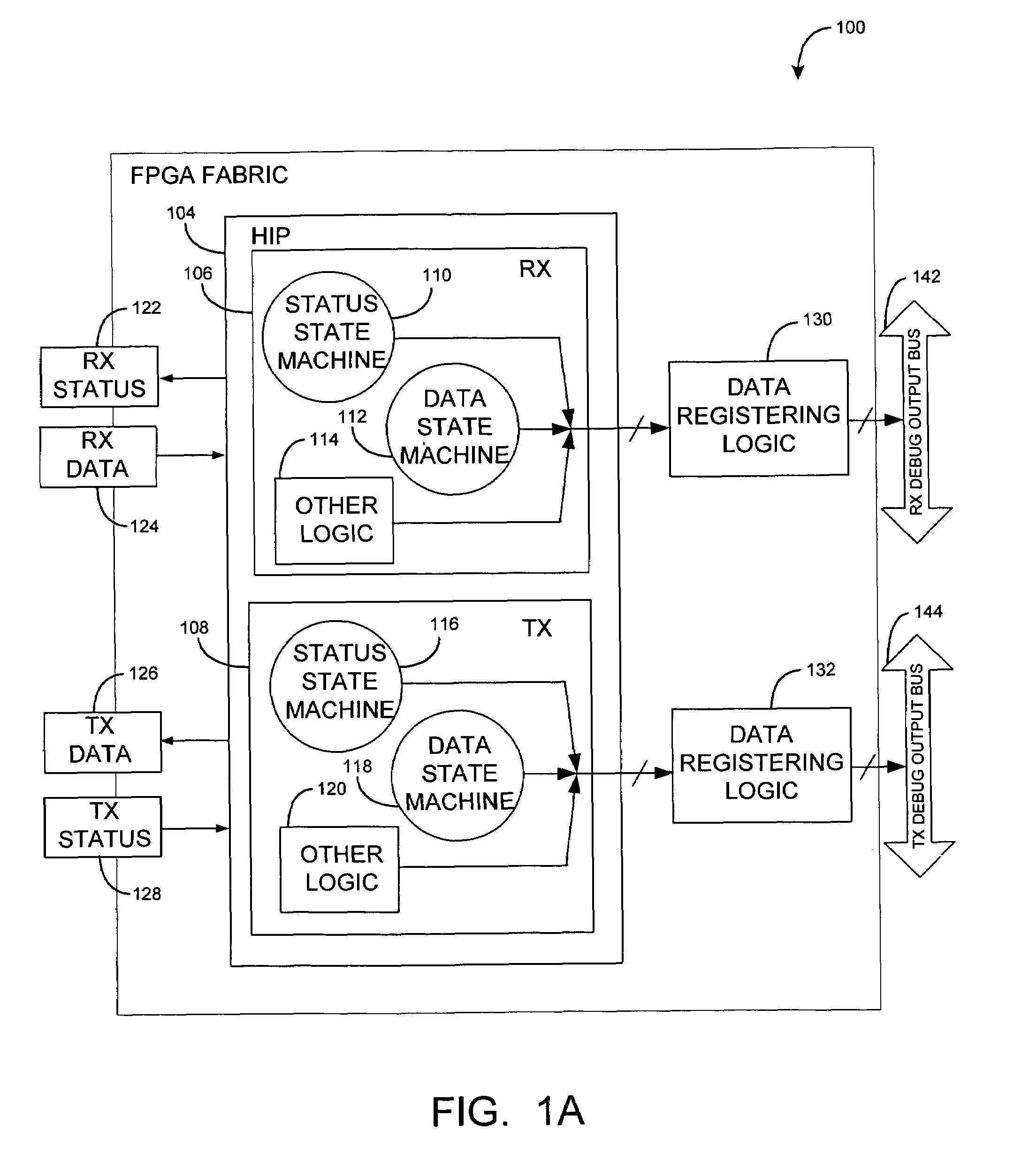

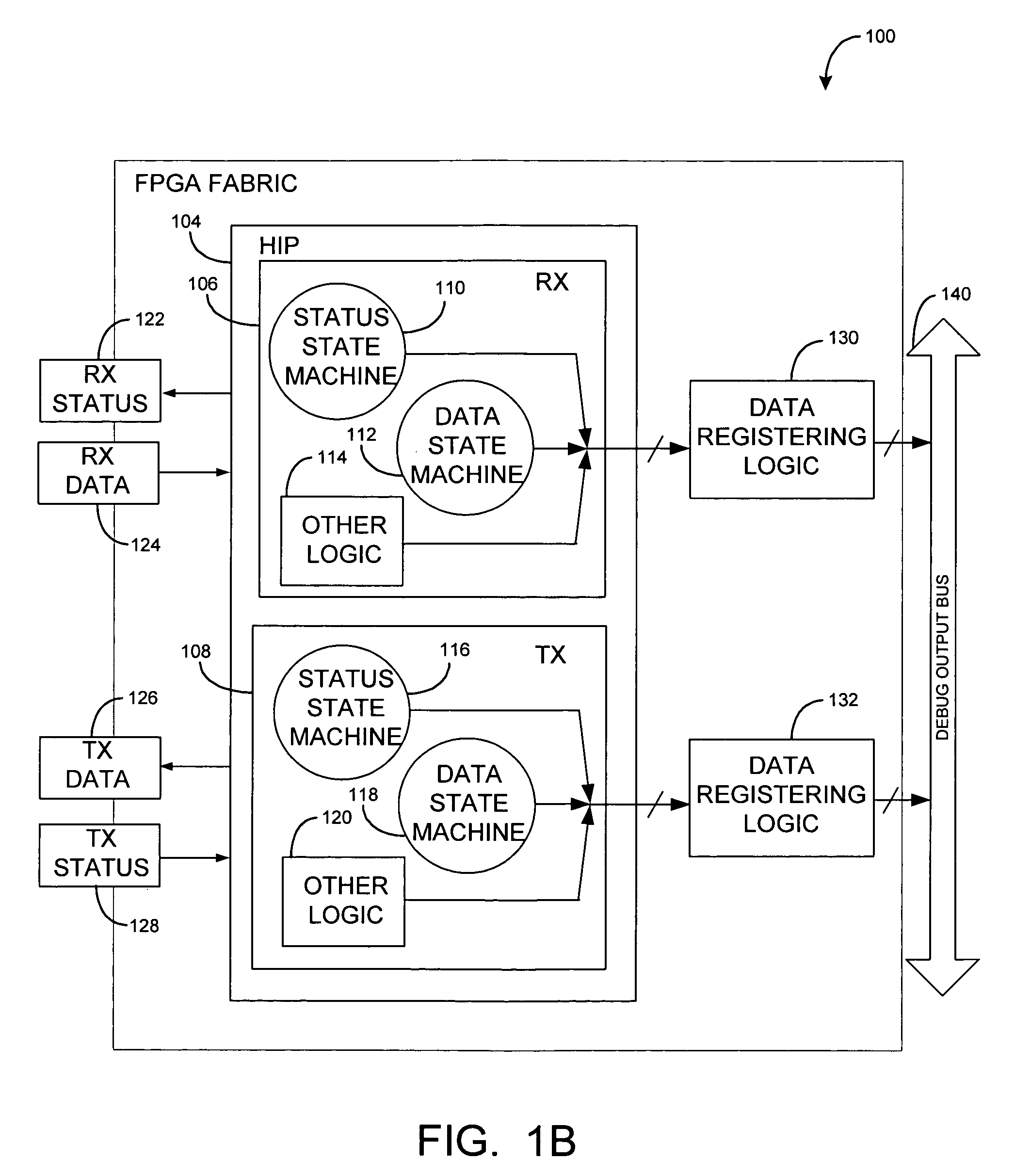

Techniques for transmitting and receiving SPI4.2 status signals using a hard intellectual property block

InactiveUS7421522B1Reduce in quantityMultiple digital computer combinationsData switching networksMultiplexingMultiplexer

Techniques for transmitting and receiving FIFO status signals on a hard intellectual property (HIP) block of a programmable logic integrated circuit are provided. The FIFO status signals are demultiplexed after being received in the HIP block and then stored in a per port context. The FIFO status signals are retrieved from a storage block in a per port context and transmitted out of the HIP block through a multiplexer. The demultiplexing and multiplexing reduces the number of input and output ports that are needed to transmit the status signals into and out of the HIP block, yet providing the necessary status throughput for a full-rate SPI4.2 status channel implementation.

Owner:ALTERA CORP

Single-level cell endurance improvement with pre-defined blocks

Owner:SANDISK TECH LLC

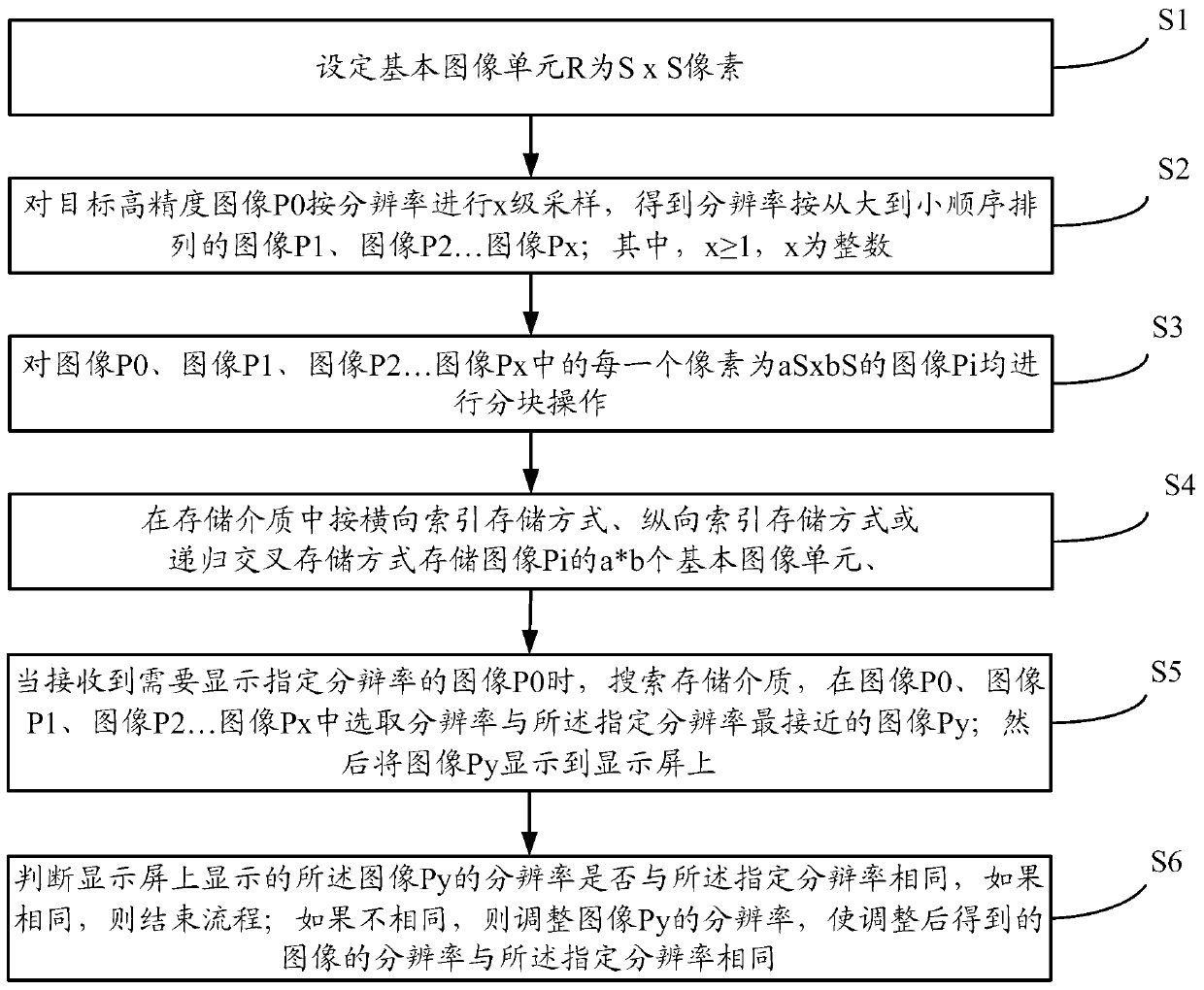

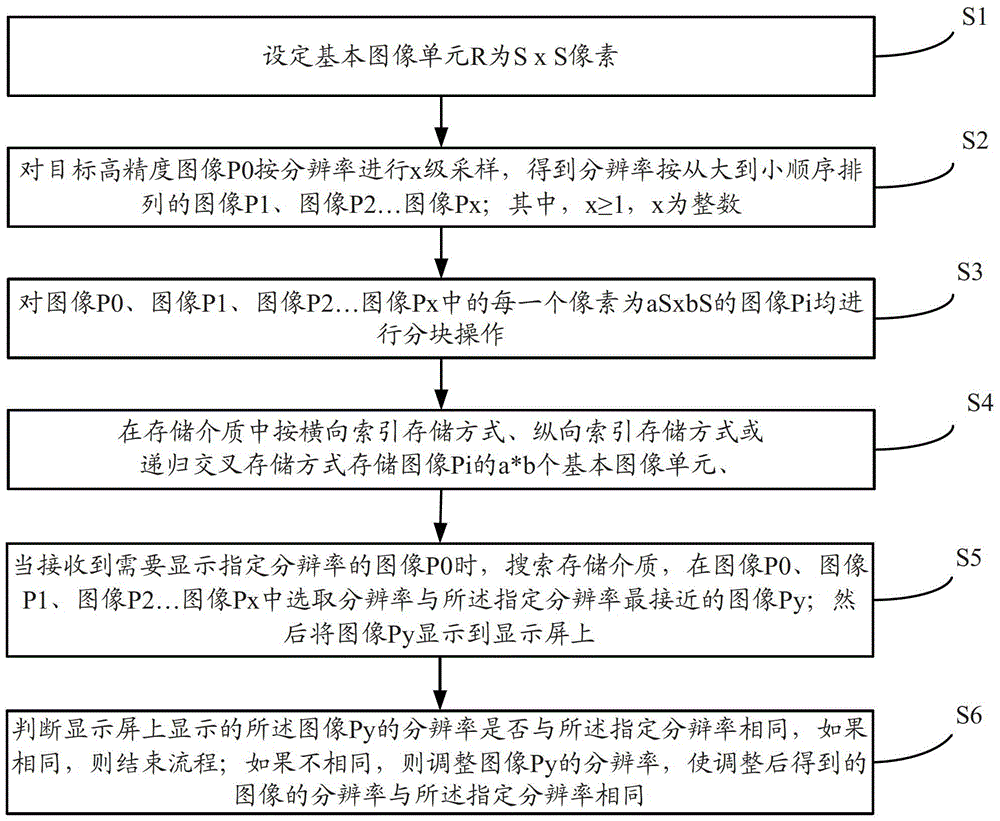

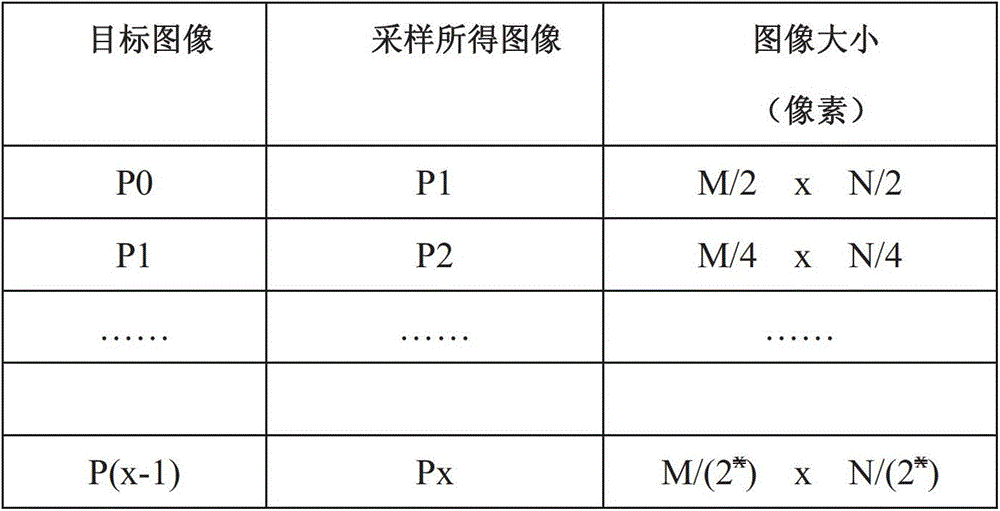

Method for speedy presentation of ultra-precise image in network environment

InactiveCN103345495AFast readQuick showSpecial data processing applicationsImage resolutionBlock techniques

The invention provides a method for speedy presentation of an ultra-precise image in the network environment. The method for the speedy presentation of the ultra-precise image in the network environment comprises the following steps of carrying out X-stage sampling on a target high-precision image P0 according to the resolution ratio of the target high-precision image to obtain an image P1, an image P2, ..., and an image Px, wherein the resolution ratios of the image P1, the image P2, ..., and the image Px become smaller gradually, X>=1, and X is an integer; blocking is carried out on each image Pi of the image P0, on each image Pi of the image P1, on each image Pi of the image P2, ..., and on each image Pi of the image Px, and obtained blocks are saved in a transverse index saving mode, in a longitudinal index saving mode and in a recursion cross saving mode; when a request for presenting the image P0 with a pointed resolution ratio is received, a storage medium is searched, and an image Py with a resolution ratio closest to the pointed resolution ratio is selected; the image Py is then displayed on a screen. According to the method for the speedy presentation of the ultra-precise image in the network environment, due to the fact that the layering and blocking technique is adopted, the target image is saved from multiple dimensions, and therefore the required image can be read and presented fast and image browsing experience is improved for users.

Owner:中科云投科技股份有限公司

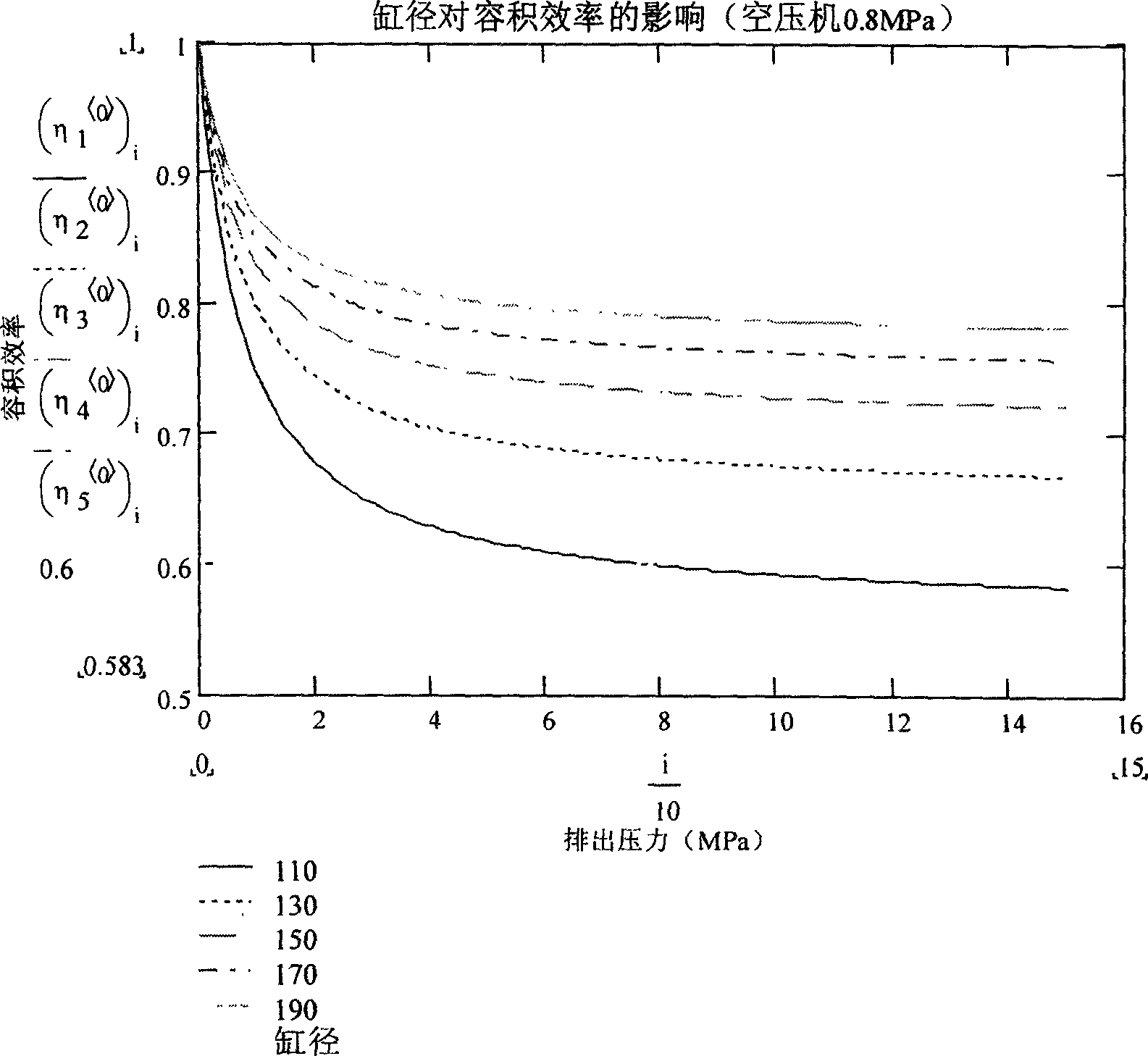

Method for feeding drilling fluid with high gas content by using reciprocating drill pump

The method of utilizing reciprocating well drilling pump in conveying drilling fluid with high gas content includes the following steps: 1) adopting reciprocating well drilling pump with large cylinder lining, great work volume and clearance volume reduced in filler block technique for efficient pumping of drilling fluid with high gas content; and 2) pumping micro foam drilling fluid with the said reciprocating drilling pump for well drilling job directly or realizing high pressure or super high pressure well drilling job via combination with other in-situ apparatus. The present invention is simple, reliable and low in cost.

Owner:SOUTHWEST PETROLEUM UNIV

Techniques for debugging hard intellectual property blocks

InactiveUS7479803B1Electrical testingElectric pulse generator circuitsProcessor registerIntellectual property

Techniques are provided to hardware debug a programmable logic integrated circuit that includes a hardware intellectual property block (HIP). The HIP includes a logic circuit and state machine(s). The state machine outputs state machine information depending on selected signals within the logic circuit. The HIP block can also output data from a number of internal registers / flip-flops. Optional data registering logic can capture the state machine information and output it to a data bus.

Owner:ALTERA CORP

On-spot leakage detection and blocking technique of whole-sealing combination electric appliance

InactiveCN103606832AQuick recoveryLeak detection is accurate and fastSwitchgearSoap bubbleEconomic benefits

The invention discloses an on-spot leakage detection and blocking technique of a whole-sealing combination electric appliance and belongs to the technical field of electric power. According to the technical scheme, leakage points of different SF6 gas leakage portions existing in operation of the whole-sealing combination electric appliance are accurately detected by flexibly utilizing the comprehensive monitoring method, the pressure lowering analyzing method, the segmentation positioning method, the local accumulation method, the soap bubble method, the sealing gum method and the like in an on-spot mode, and therefore leakage blocking processing techniques such as strict techniques, welding joint repairing, sample stamping and blocking, pressing cap additionally arranging and part replacing can be implemented in a targeted mode, and equipment operation is fast recovered. The on-spot leakage detection and blocking technique of the whole-sealing combination electric appliance has the advantages of being simple, convenient to use, easy to perform, accurate and fast in leakage detection, capable of lowering the blindness, simple and effective in leakage blocking, capable of reducing the workload, low in maintaining cost, high in maintenance efficiency, capable of reducing outage of equipment and ensuring safety operation of the equipment and obvious in social and economic benefit.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

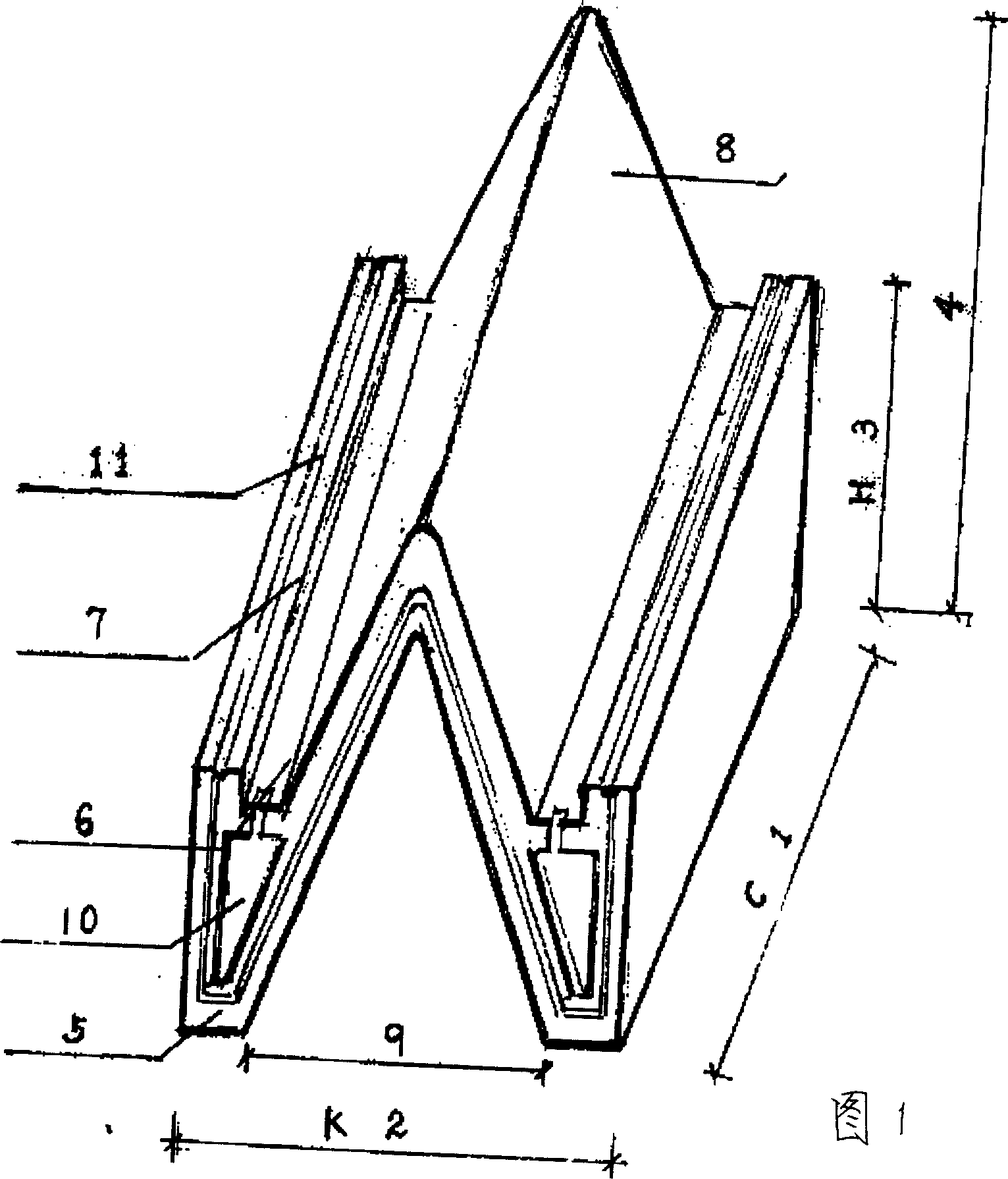

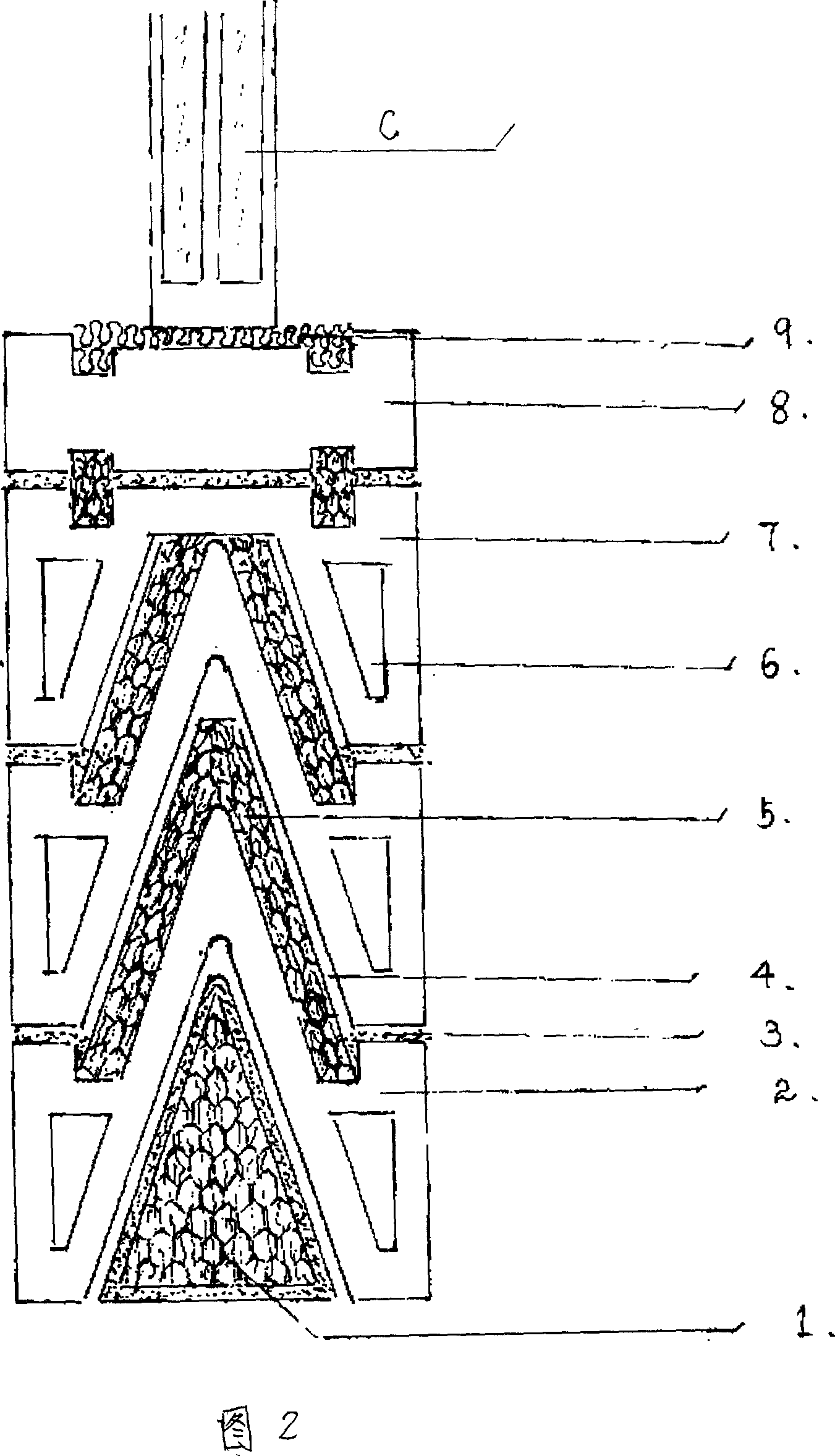

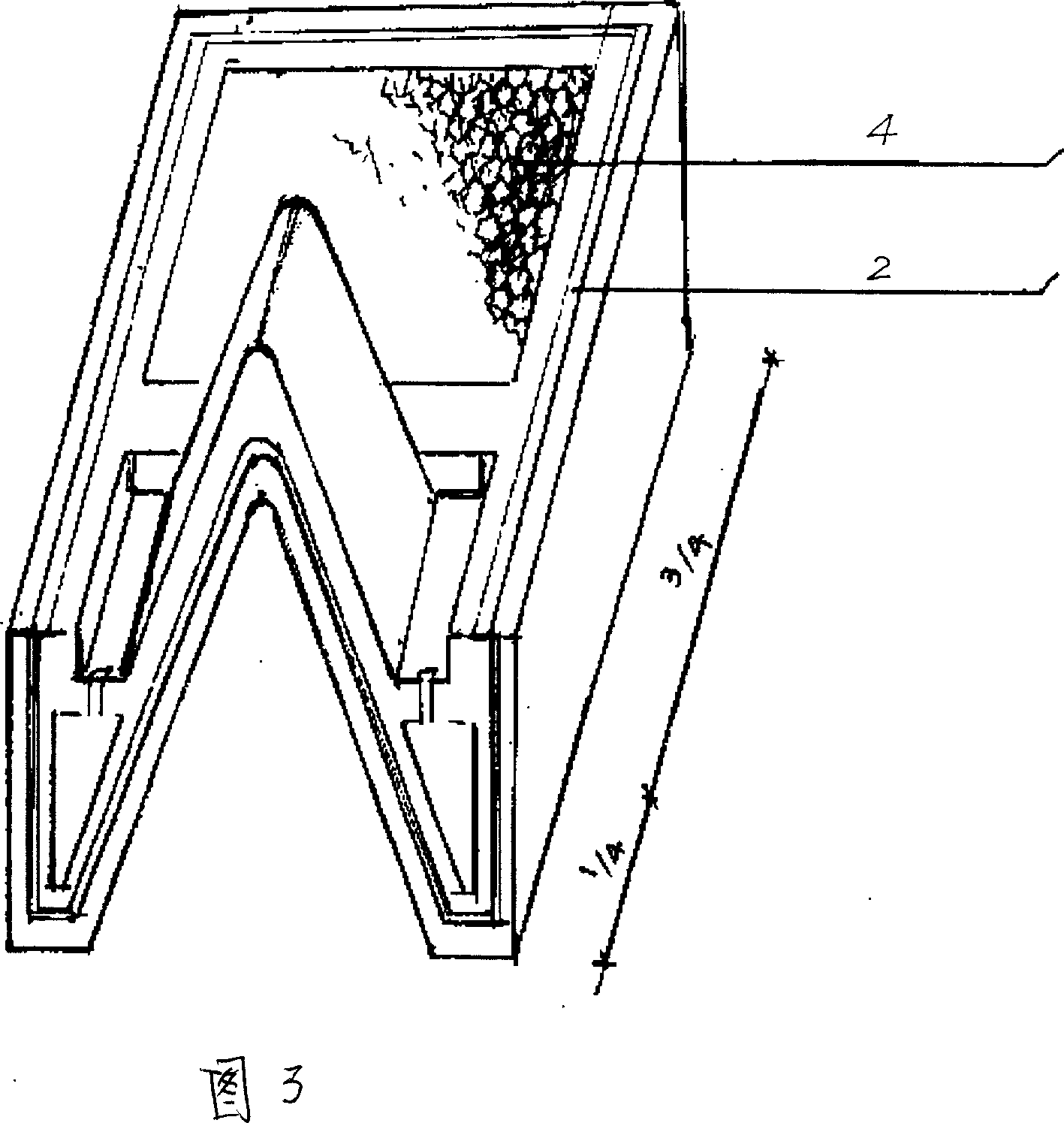

Returning filter air-conditioning building block technique of heat bridge interface and application

InactiveCN101004093AMake up for the lack of commonalityConstruction materialWallsBrickThermal bridge

The present invention provides a heat-bridge interface reverse-filtering air-conditioning block technique and its application. It is characterized by that said technique utilizes improvement of brick machine die equipment, at the same time of selecting and using conventional material utilizes the good bending strength and durability of tuffaceous material to produce the invented heat-bridge interface reverse-filtering air-conditioning block. Said invention also provides the concrete structure of said air-conditioning block, its working principle and concrete construction method.

Owner:姚福祥 +1

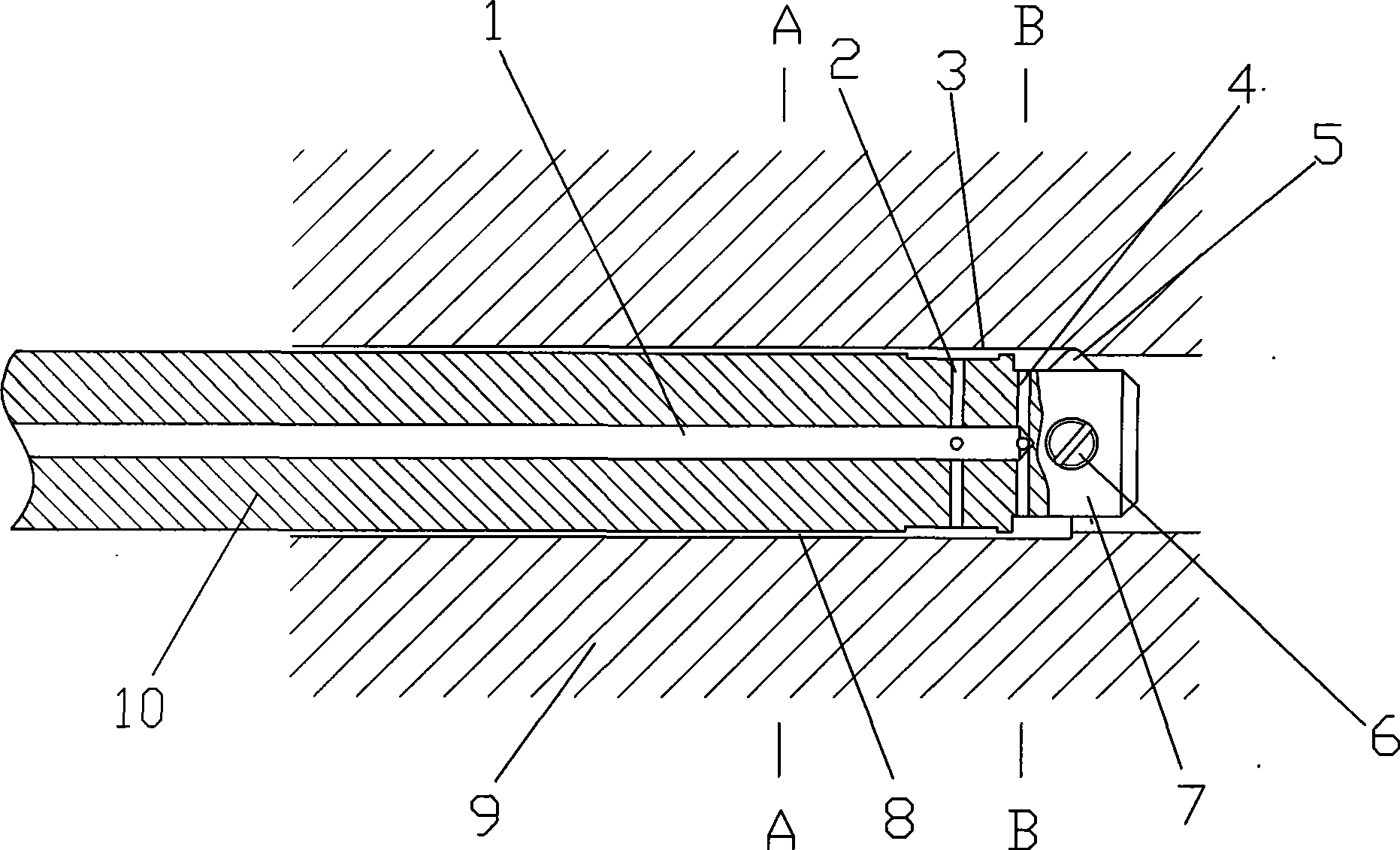

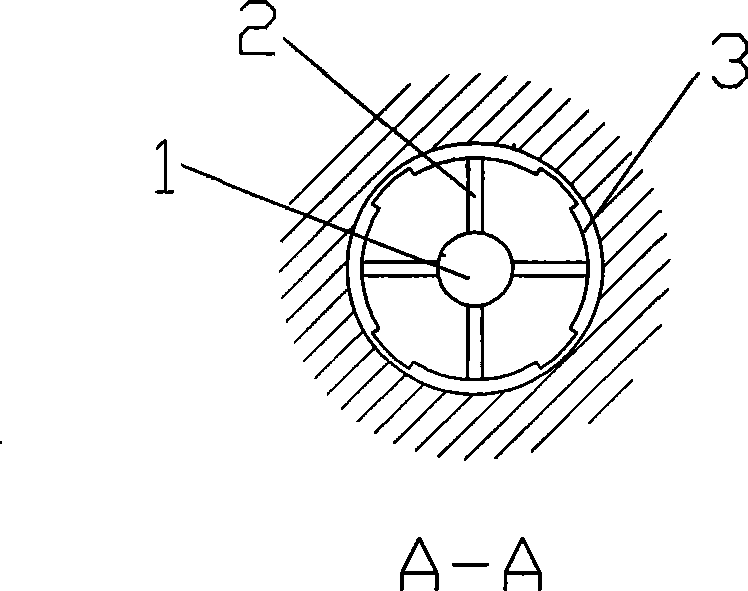

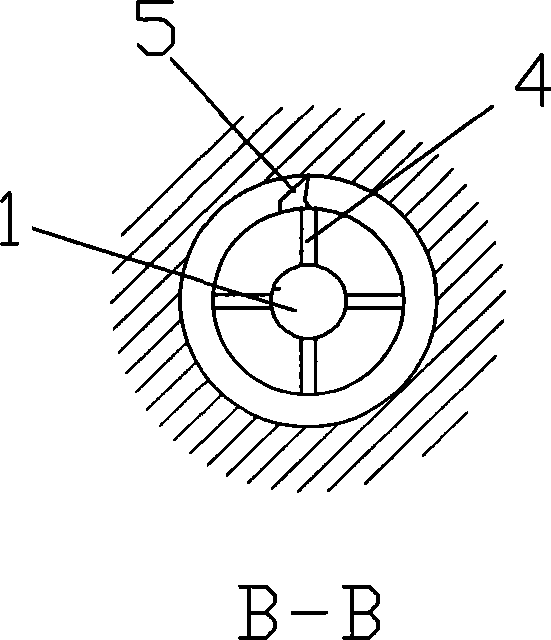

Hydrostatic pressure auxiliary shoring cutter-holder and shoring method

InactiveCN101396742AReduce the amount of bending deformationReduce vibrationBoring barsTurning toolsHydrostatic pressureEngineering

The invention relates to a hydrostatic pressure auxiliary support tool bar and a support method thereof. The hydrostatic pressure auxiliary support tool bar is provided with a bar head used for installing a tool bit, a bar neck provided with a cutting liquid flow channel and a bar body used as a bar head support member, wherein, a central axial hole of the bar body is arranged as a cutting liquid feeding channel which is communicated with the cutting liquid flow channel arranged on the bar neck. The invention is characterized in that a plurality of independent bearing grooves are evenly distributed on the surface of the bar body along outer circumference and the liquid feeding channel is respectively communicated with each bearing groove through each pore throttle channel. As the 'flexible' support is adopted in the invention, manpower adjustment are unnecessary, the effect for absorbing the vibration of a tool is better, the surface of a processed pore can not be damaged, simultaneously, the hydrostatic pressure auxiliary support tool bar can be used together with the existing support bar or support block technique.

Owner:HEFEI UNIV OF TECH

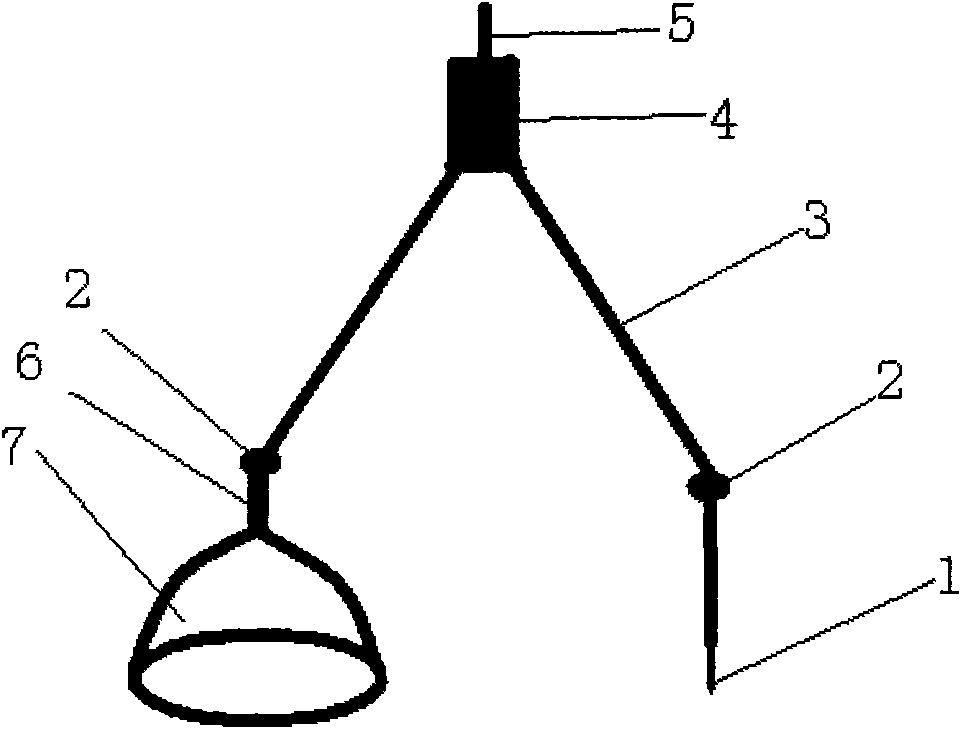

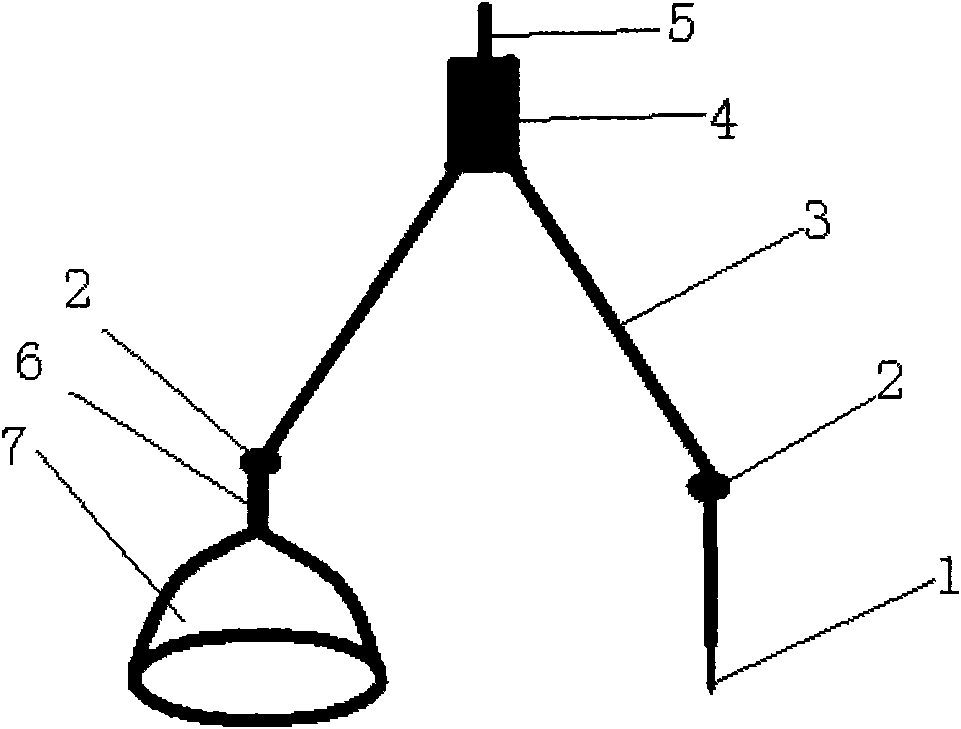

Breast reduction operation line drawing instrument by round block technique

The invention discloses a breast reduction operation line drawing instrument by a double-ring technique, which is mainly applied to the breast reduction operation adopting the double-ring technique and comprises two reverse V-shaped compass legs connected to an angle demodulator, wherein a line drawing knob is arranged on the angle demodulator, the front end of one compass leg is provided with a line drawing pen head, and the front end of the other compass leg is provided with a freely rotatable nipple sleeve ring. When the line drawing instrument is used, the operation design time is obviously shortened, the line drawing time before operation can be greatly saved, materials of the instrument can be easily obtained, the manufacture is simple, the operation is convenient, the double-side incision design is symmetrical, the error is smaller, and the operative incision is specific and digital and can be conveniently used as data reference for subsequent academic summary.

Owner:褚福海

Dedusting and denitration integrated catalyst used for smoke-gas treatment and preparation method of dedusting and denitration integrated catalyst

InactiveCN107999054AExtended stayImprove efficiencyDispersed particle filtrationCatalyst activation/preparationRetention timeHoneycomb

The invention relates to a dedusting and denitration integrated catalyst used for the smoke-gas treatment and a preparation method of the dedusting and denitration integrated catalyst, and belongs tothe technical field of catalysts. The method comprises five processes of mixing, extruding, drying, blocking a hole and calcining. The method changes the states of various through holes in a traditional honeycomb type SCR catalyst through the blocking technique, the smoke gas enters from an inlet end of the honeycomb type catalyst, and passes through the side wall of an adjacent hole of an unclosed hole on the inlet end, the smoke gas is fully filtered through the side wall, and the smoke dust is removed. Therefore, the purpose of dedusting is fulfilled, the retention time of the smoke gas inthe catalyst is also prolonged, the contact area between the smoke gas and the catalyst is increased, the efficiency of the catalyst is improved, meanwhile, the variety and the use level of a pore forming material are limited, the pore size distribution on the side wall in the integrated catalyst is changed, so that the catalyst is suitable for removing the dusts at various particle sizes, the purpose of simultaneously denitrating and dedusting is fulfilled finally, the integration of denitrating and dedusting is realized in the real sense, and the operation costs for smoke-gas treatment and investment in environmental protection are greatly reduced in a power plant and an industrial furnace.

Owner:CHONGQING YUANDA CATALYST MFG

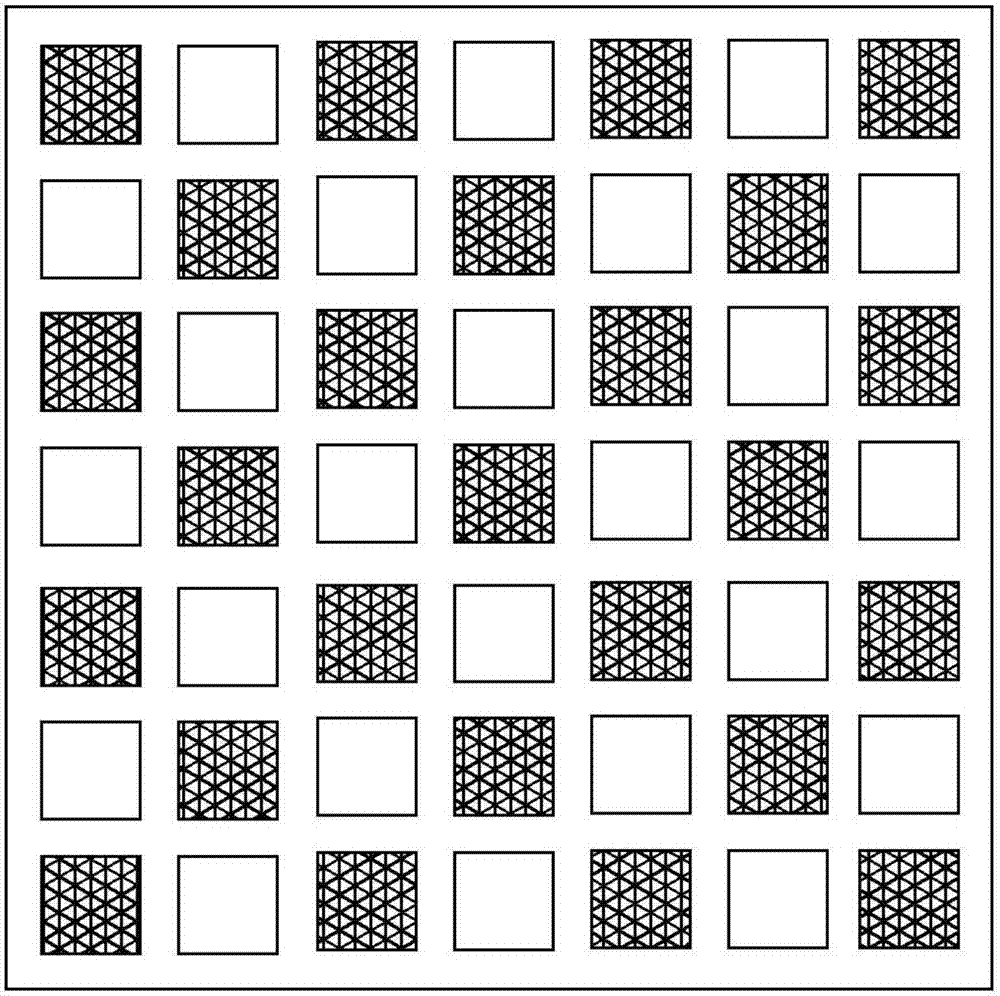

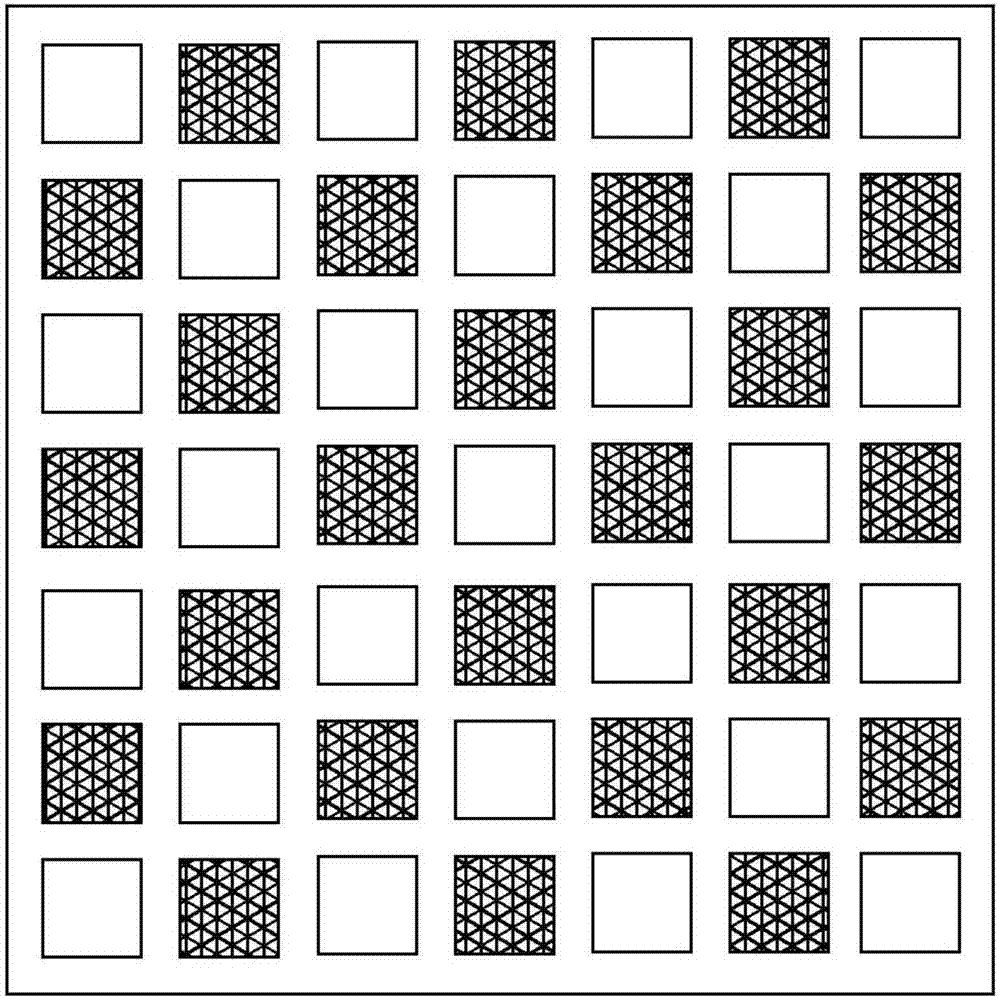

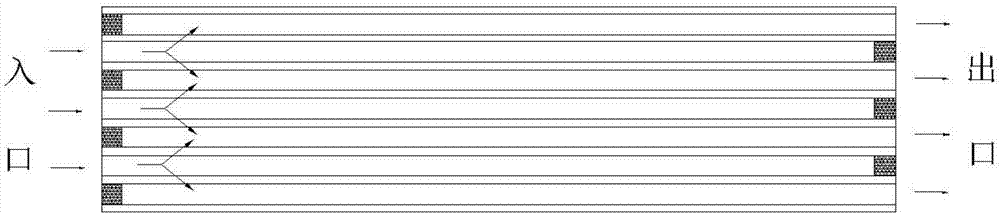

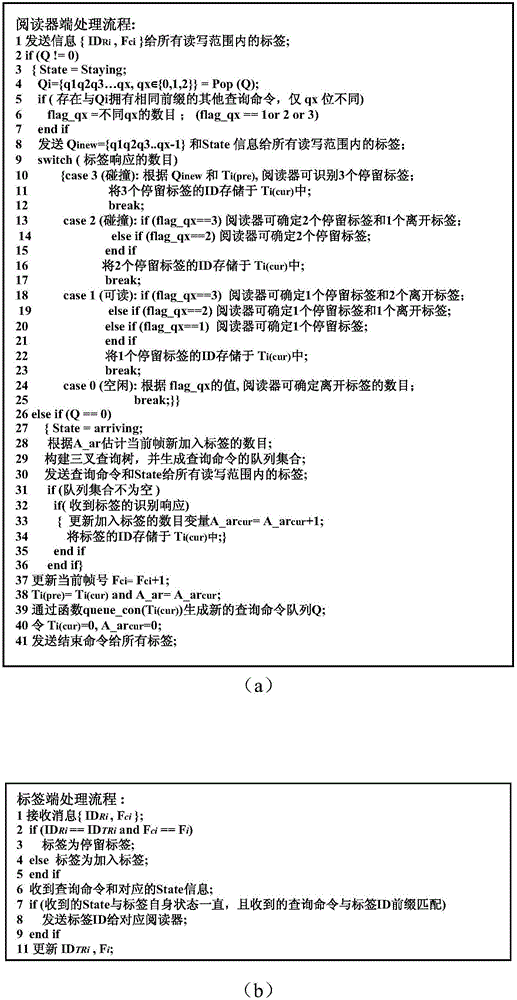

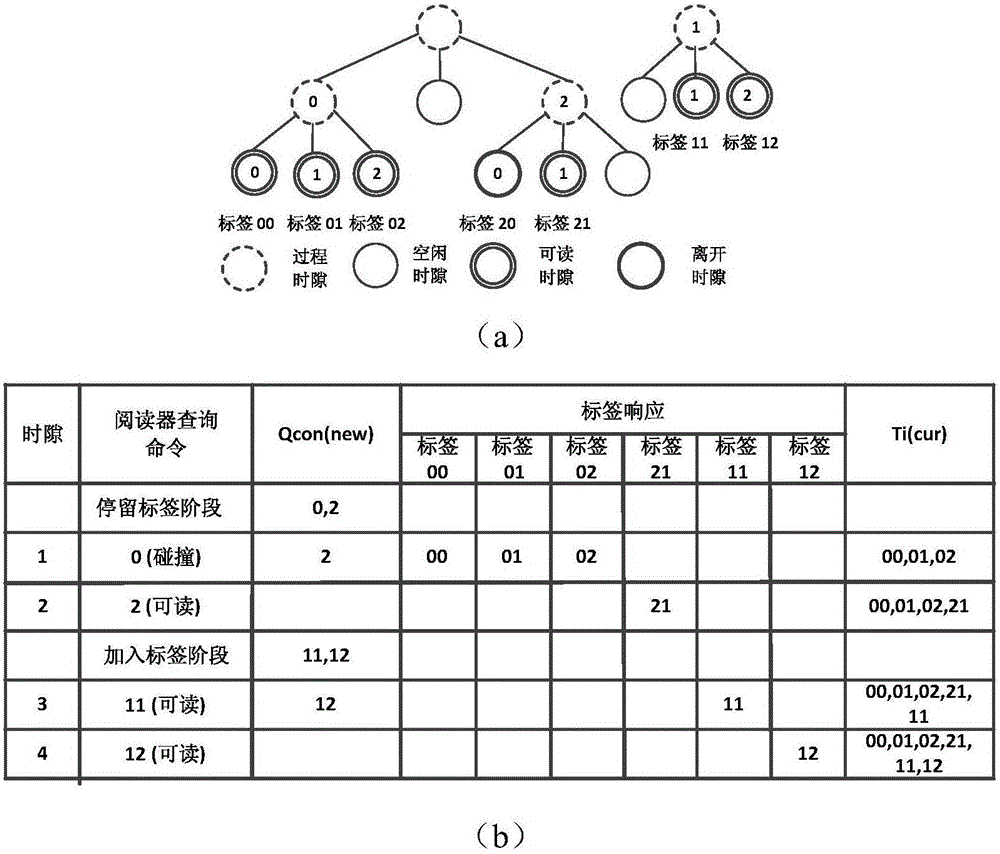

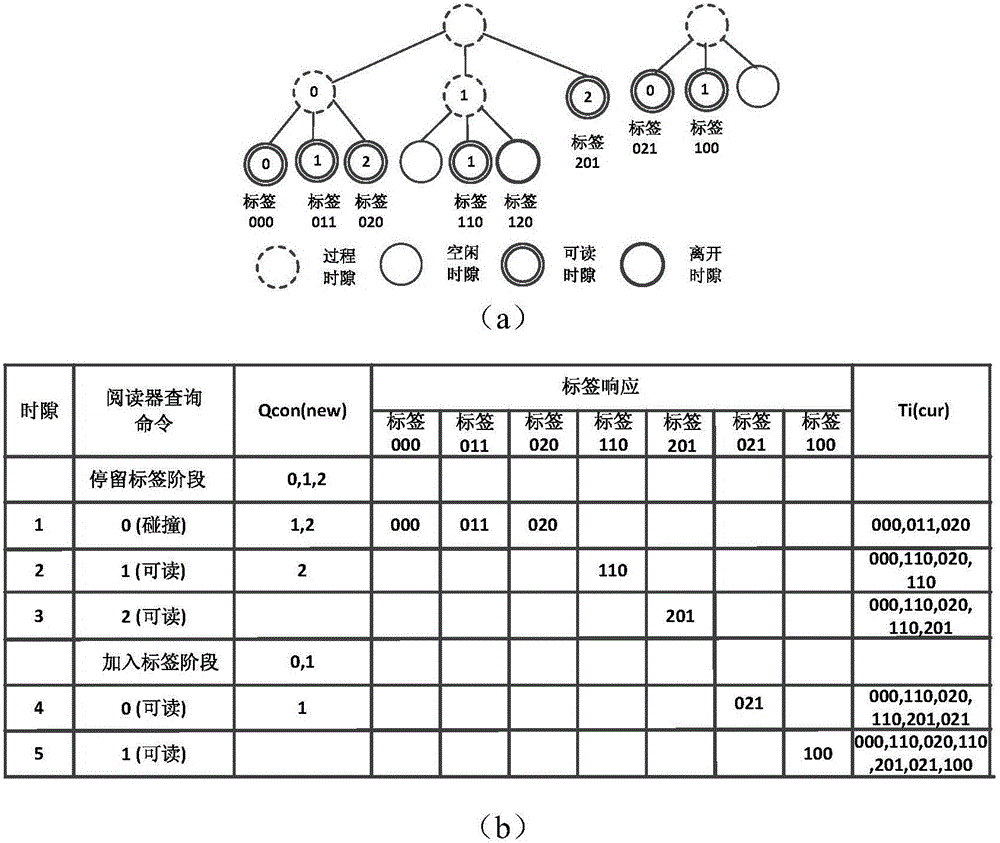

Label anti-collision method based on self-adaption ternary inquiry split in mobile RFID system

InactiveCN106156681AImprove performanceReduce the numberSensing by electromagnetic radiationPresent methodBlock techniques

The invention discloses a label anti-collision method based on self-adaption ternary inquiry split in a mobile RFID system. The label anti-collision method is adopted for solving the technical problem of poor label recognition capability of the present method. According to the technical scheme, a corresponding conversion formula is given according to the relationship between binary representation and ternary representation of the label ID sequence, a ternary inquiry tree is built and the property of a tree type recognition scheme is optimized, so that the application problem of ternary inquiry split is solved. A ternary solution is put forward according to the ternary inquiry split characteristics of inquiry order in the ternary inquiry tree, so that the original remaining label in a read-writing area is quickly recognized and the quantity of the inquiry orders is reduced; the ternary inquiry tree scheme is utilized to recognize the newly added label and the length of the inquiry orders can be shortened, so that the technical problem of poor label recognition capability is effectively solved; the split block technique is utilized to respectively solve the information collision problem of the original remained label and the newly added label; on the basis, a novel communication flow for label recognition is designed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Detection method for Her-2 genes of circulating tumor cells in peripheral blood of later-period breast cancer patient

ActiveCN105606824AAvoid false negativesAvoid difficultiesBiological material analysisBiological testingOncologyBlock techniques

The invention discloses a detection method for Her-2 genes of circulating tumor cells in peripheral blood of a later-period breast cancer patient. The detection method comprises the steps that the CTCs in the peripheral blood of the later-period breast cancer patient are separated and acquired through a film filtering device; the circulating tumor cells in the peripheral blood of the later-period breast cancer patient are identified through a cellular immunity fluorescent technique; thin sections are made through a cell wax block technique; the expression condition of the Her-2 of the circulating tumor cells in the peripheral blood of the later-period breast cancer patient is detected through an immunologic tissue chemical technique. According to the detection method, the enrichment CTCs are separated with the help of an ISET technique, the CTCs are identified by depending on the cellular immunity fluorescent technique, and therefore the difficulties existing in CTC identification only through the ISET technique and the false negativity existing in CTC identification only through an immunological detection technique are overcome; meanwhile, the requirement on equipment is not high, the method is easy to master, and real-time monitoring can be achieved. Through the technical method, the expression condition of the Her-2 of the later-period breast cancer patient can be detected without needing to sample the breast cancer tissue.

Owner:山东喻晓生物科技有限公司

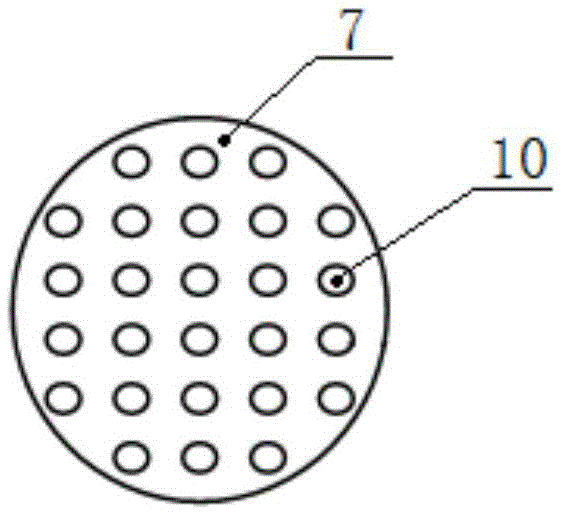

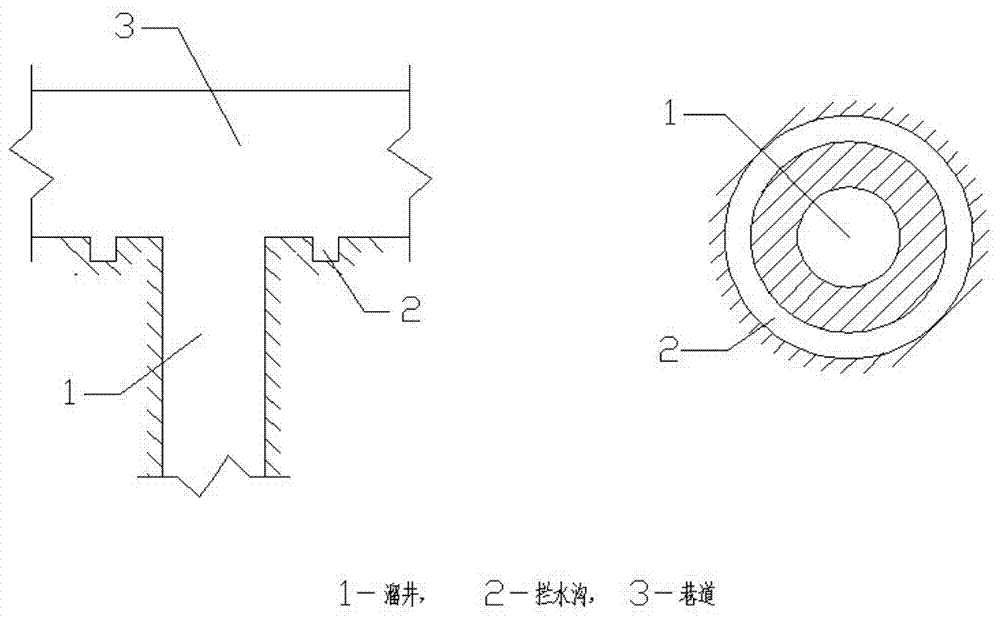

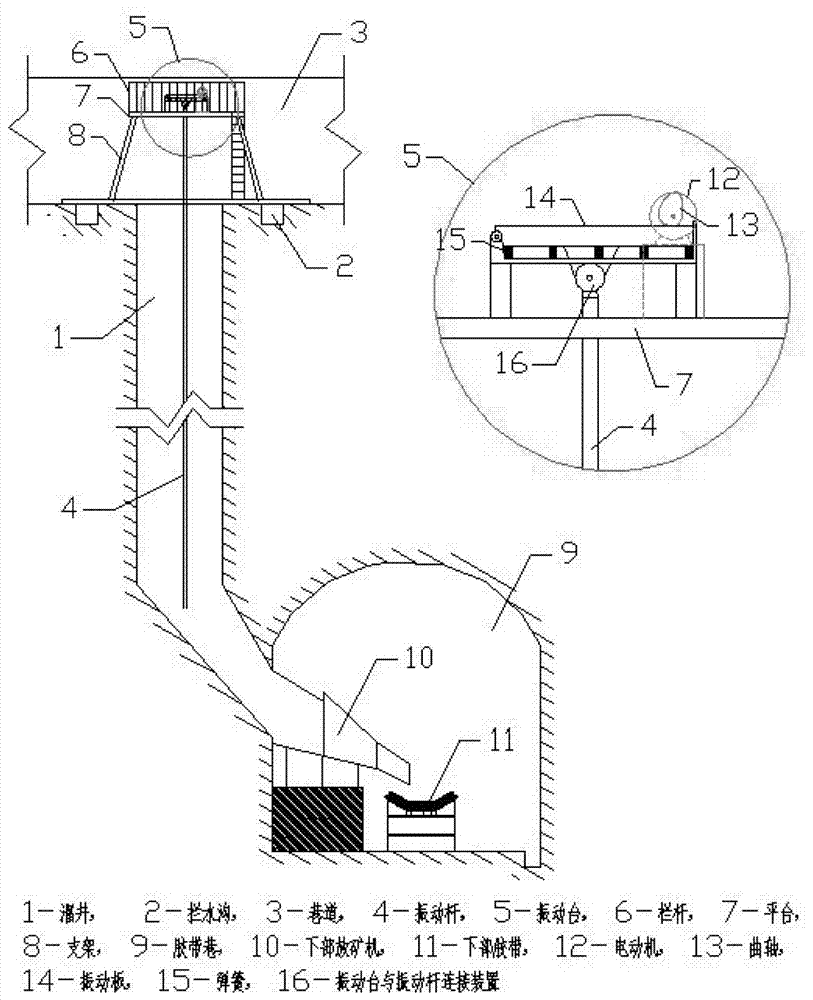

Anti-blocking technique for stored ores of high orepass during phosphate ore mining

ActiveCN107339106APrevent chutes from cloggingPrevent dredging chute blockageUnderground miningSurface miningSmall amplitudeVibration control

The invention discloses an anti-blocking technique for stored ores of a high orepass during phosphate ore mining. A vibration table is arranged at an upper opening of the orepass; a vibration rod downwards stretches into the orepass, and when the vibration table works, the vibration rod is used for vibrating slag in the orepass. The technique is simple; the vibration rod is installed in the orepass directly; when the orepass is not blocked, a vibration facility does not need to be started; when vibration dredging is needed, a starting button is operated, and therefore operation is easy; and the safety and reliability coefficients are high, and the slag is loosened and discharged directly through small-amplitude vibration of a steel pipe.

Owner:远安县燎原矿业有限责任公司

A Method of Webpage Text Extraction

InactiveCN103530429BImprove work efficiencyImprove accuracyText processingSemi-structured data retrievalBlock techniquesBlocking techniques

The invention provides a webpage content extracting method. The method comprises the following steps of I, preprocessing a webpage, II, searching for the longest series in the webpage, III, establishing a DOM tree and searching for the nodes corresponding to the longest series according to the DOM tree, IV, determining a beginning node and a finishing node according to labels of the nodes corresponding to the longest series, V, checking and filtering the beginning node and the finishing node, and VI, outputting text in the filtered beginning node and text in the filtered finishing node. The method overcomes the defect of a module or blocking technique in news content extraction application, searches for seed paragraphs based on the longest series and improves webpage content extracting work efficiency and accuracy.

Owner:北京中搜云商网络技术有限公司

Detection method of pr gene in peripheral blood circulating tumor cells of patients with advanced breast cancer

ActiveCN105606823BAvoid false negativesAvoid difficultiesBiological material analysisBiological testingOncologyNon invasive

Owner:山东发现生物技术有限公司

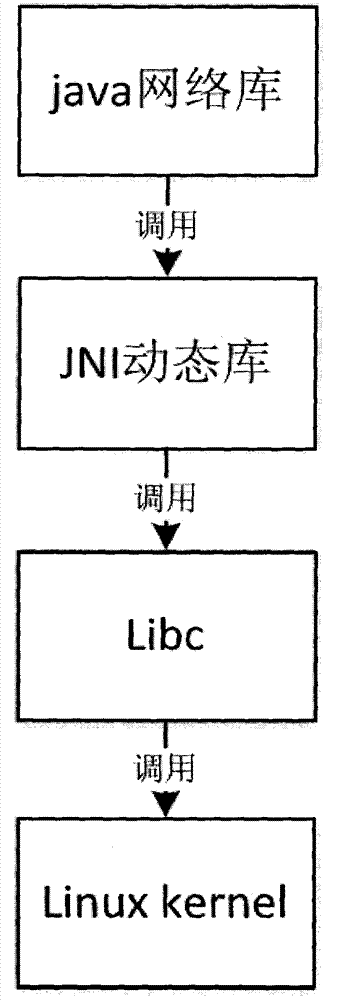

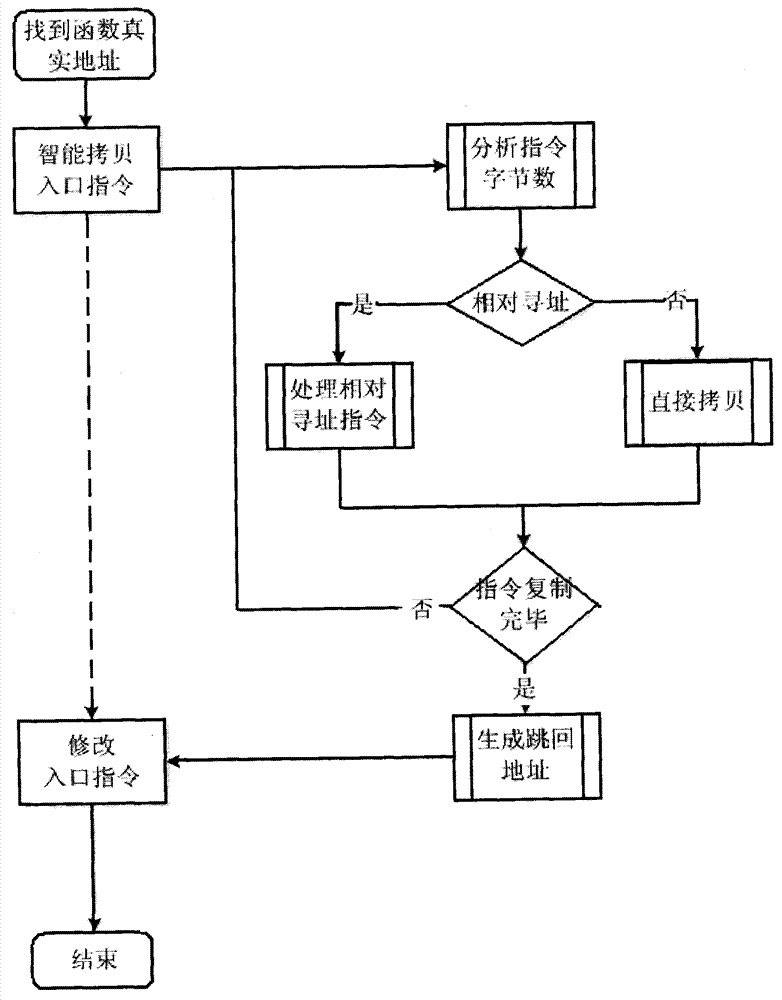

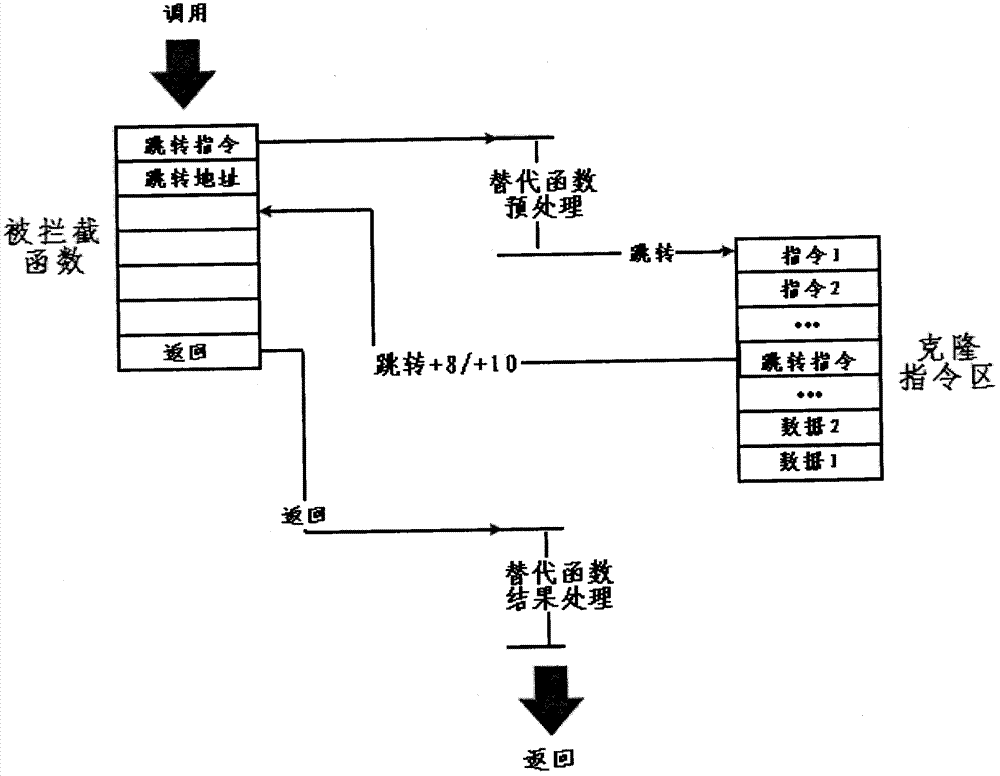

Mobile app performance data collection method based on function interception technology

ActiveCN104951375BNo risk of errors in operationEnsure correct executionInterprogram communicationPerformance functionUnix domain socket

The invention discloses a mobile phone APP performance data collection method based on function interception technology. The specific implementation of the collection method is divided into three steps: before the target APP starts, use ptrace call to inject its own dynamic library S into the zyogte process, After the Inline Hook is completed; start the app process, and when network interaction occurs, the application will call the intercepted network function; in the part of the alternative function result processing, use the inter-process communication means provided by Android or Linux, UNIX domain socket, or local Socket, send the data to the data collection process; in this way, the network data collection of the target APP is completed. If the present invention needs to intercept network calls, it only needs to process the LibC dynamic library. The method provided by the invention modifies the machine code instruction of the target function, and the interception rate is 100%.

Owner:北京博睿宏远数据科技股份有限公司

Ultra-fast display method of ultra-precise images in network environment

InactiveCN103345495BFast readQuick showSpecial data processing applicationsComputer graphics (images)Image resolution

The invention provides a method for speedy presentation of an ultra-precise image in the network environment. The method for the speedy presentation of the ultra-precise image in the network environment comprises the following steps of carrying out X-stage sampling on a target high-precision image P0 according to the resolution ratio of the target high-precision image to obtain an image P1, an image P2, ..., and an image Px, wherein the resolution ratios of the image P1, the image P2, ..., and the image Px become smaller gradually, X>=1, and X is an integer; blocking is carried out on each image Pi of the image P0, on each image Pi of the image P1, on each image Pi of the image P2, ..., and on each image Pi of the image Px, and obtained blocks are saved in a transverse index saving mode, in a longitudinal index saving mode and in a recursion cross saving mode; when a request for presenting the image P0 with a pointed resolution ratio is received, a storage medium is searched, and an image Py with a resolution ratio closest to the pointed resolution ratio is selected; the image Py is then displayed on a screen. According to the method for the speedy presentation of the ultra-precise image in the network environment, due to the fact that the layering and blocking technique is adopted, the target image is saved from multiple dimensions, and therefore the required image can be read and presented fast and image browsing experience is improved for users.

Owner:中科云投科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com