Dedusting and denitration integrated catalyst used for smoke-gas treatment and preparation method of dedusting and denitration integrated catalyst

A catalyst and denitration technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increased volume usage, small specific surface area, short service life, etc. process, increase the contact area, and facilitate the effect of on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of dust removal and denitrification integrated catalyst

[0031] (1) Mixing: by mass parts, weigh 90 parts of TiO 2 Powder, 0.5 parts of ammonium metavanadate, 5 parts of ammonium metatungstate, 1 part of carboxymethyl cellulose, 2 parts of stearic acid, 4 parts of montmorillonite, 30 parts of wood chips, 8 parts of glass fiber, 30 parts of ammonia and 50 parts 1 part deionized water, after mixing well, the plastic clay was obtained;

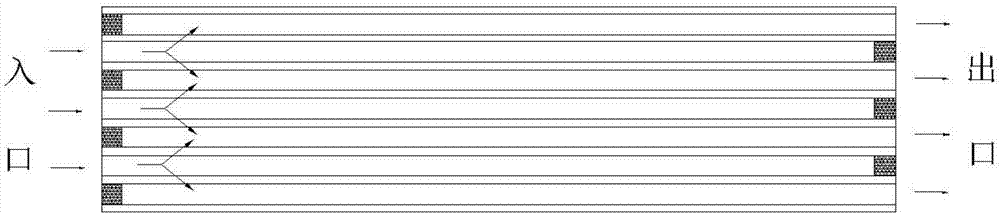

[0032] (2) Extrusion: Extrude the molding clay prepared in the step (1) as a whole to obtain a shaped honeycomb catalyst body;

[0033] (3) Drying: drying the green body prepared in step (2) at 60° C. for 300 h;

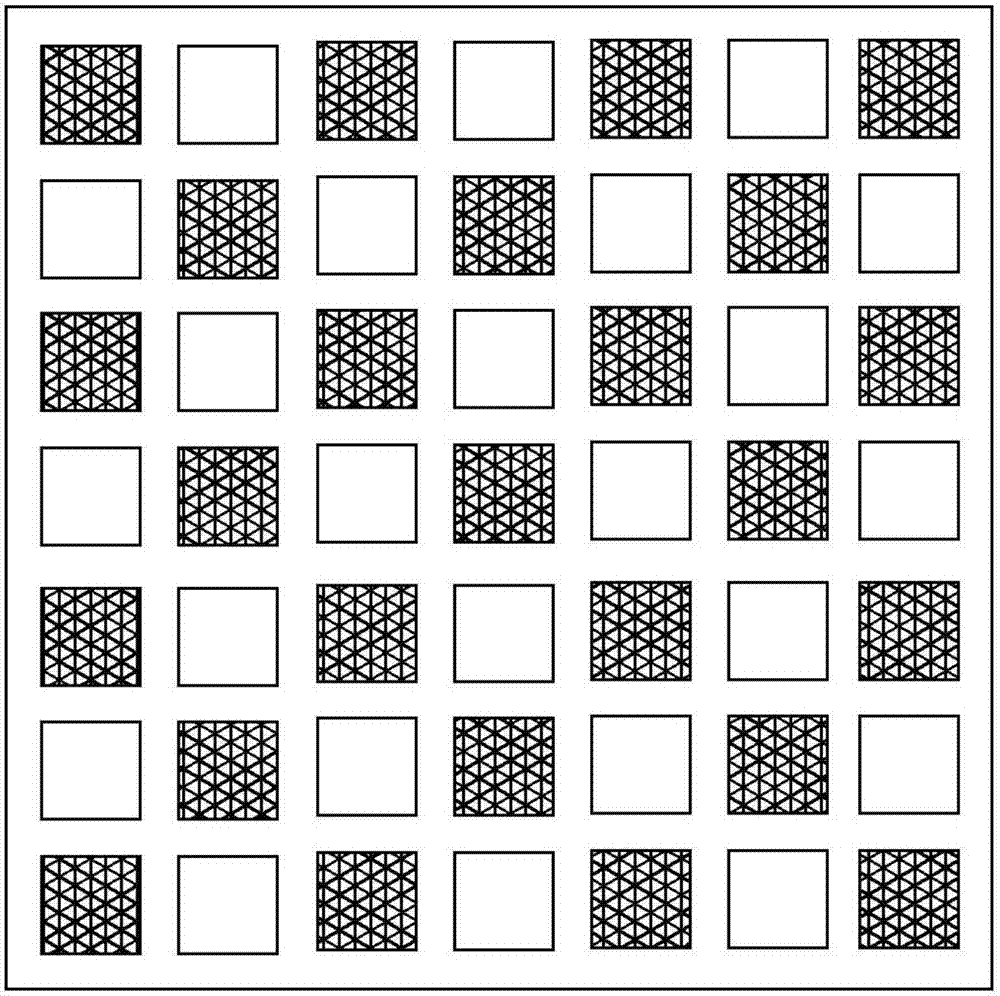

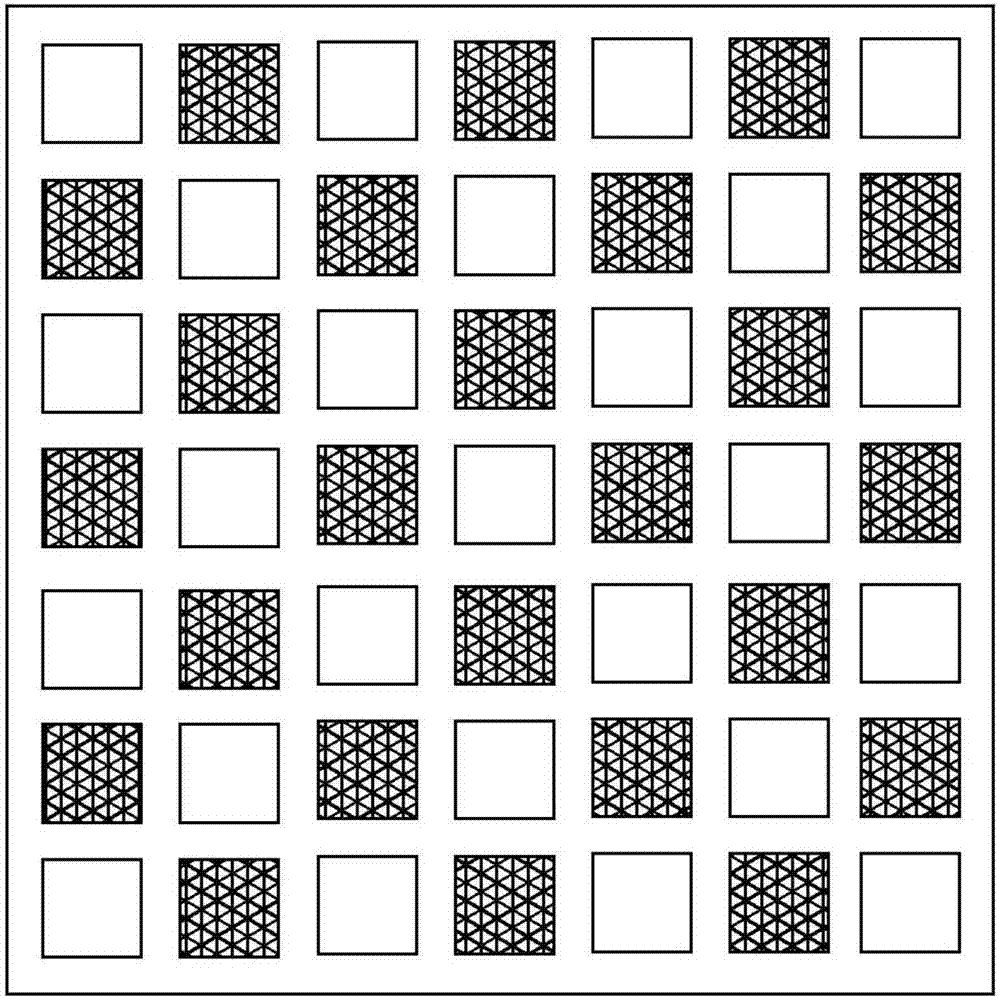

[0034] (4) Hole plugging: Use the plugging material prepared in step (1) and the special inorganic glue TW26641 for natural stones in a mass ratio of 1:5 to treat the body after step (3) Staggered blocking holes at both ends;

[0035] (5) Calcination: calcining the green body treated in step (4) with gradient tem...

Embodiment 2

[0037] Preparation of dust removal and denitrification integrated catalyst

[0038] (1) Mixing: by mass parts, weigh 90 parts of TiO 2 Powder, 6 parts of ammonium metavanadate, 8 parts of ammonium metatungstate, 2 parts of carboxymethyl cellulose, 1 part of polyethylene oxide, 2 parts of stearic acid, 3 parts of montmorillonite, 20 parts of activated carbon, 5 parts of glass fiber , 30 parts of ammonia water and 40 parts of deionized water, after mixing thoroughly, the molding mud is obtained;

[0039] (2) Extrusion: Extruding the molding clay prepared in the step (1) as a whole to obtain a shaped honeycomb catalyst body;

[0040] (3) Drying: drying the body prepared in step (2) at 70°C for 250 hours;

[0041] (4) Hole plugging: Use the plugging material prepared in step (1) and high temperature resistant glue SL8303 in a mass ratio of 1:3 to carry out both ends of the green body after step (3). staggered plugging;

[0042] (5) Calcination: calcining the green body treated i...

Embodiment 3

[0044] Preparation of dust removal and denitrification integrated catalyst

[0045] (1) Mixing: by mass parts, weigh 100 parts of TiO 2 Powder, 1 part of ammonium metavanadate, 3.5 parts of ammonium metatungstate, 2 parts of hydroxypropyl carboxymethyl cellulose, 1 part of glycerin, 2 parts of montmorillonite, 20 parts of ammonium bicarbonate, 8 parts of glass fiber, 20 parts Ammonia and 40 parts of deionized water, after mixing thoroughly, make the shaping clay;

[0046] (2) Extrusion: Extrude the molding clay prepared in the step (1) as a whole to obtain a shaped honeycomb catalyst body;

[0047] (3) drying: drying the body prepared in step (2) at 80°C for 220 hours;

[0048] (4) Hole plugging: Use the plugging material prepared in step (1) and the special inorganic glue TW26641 for natural stone in a mass ratio of 1:4 to treat the body after step (3) Staggered blocking holes at both ends;

[0049] (5) Calcination: calcining the green body treated in step (4) with gradie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com