Method for feeding drilling fluid with high gas content by using reciprocating drill pump

A drilling pump and drilling fluid technology, used in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve the problems of high maintenance cost, insufficient pressure of high-pressure air compressor, complicated maintenance technology, etc. Gas drilling fluid, simple method, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

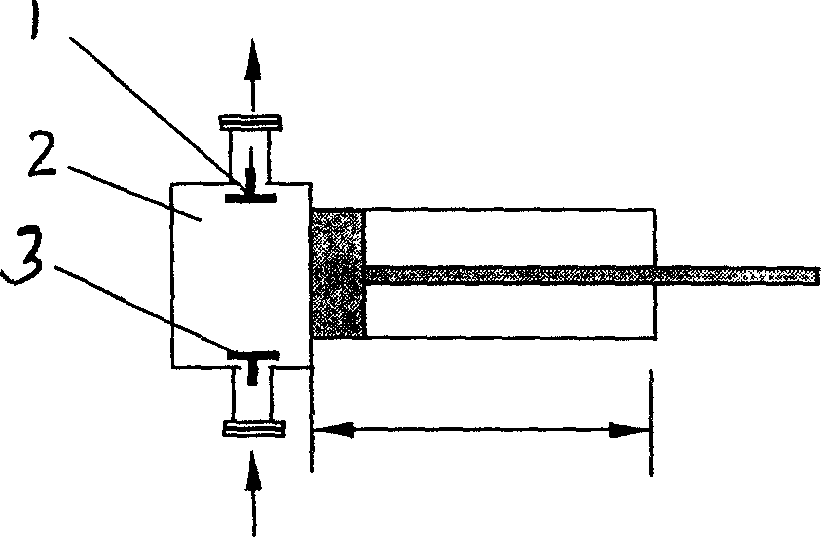

[0043] Example 1: Efficient pumping of microfoam drilling fluid for drilling operations.

[0044] When microfoam drilling is adopted, the modified reciprocating drilling pump and matching injection pump are directly used to realize the method. Figure 6 The flow chart of realizing microfoam drilling fluid drilling for this method. Its working process is as follows: the microfoam drilling fluid 7 is injected into the modified reciprocating drilling pump 9 through the infusion pump 8, and enters the wellbore 10 through the discharge pipeline after compression, thereby achieving the purpose of efficiently pumping the microfoam drilling fluid. For a microfoam drilling fluid with a given gas content, its pumping efficiency can be determined by a corresponding calculation program.

Embodiment 2

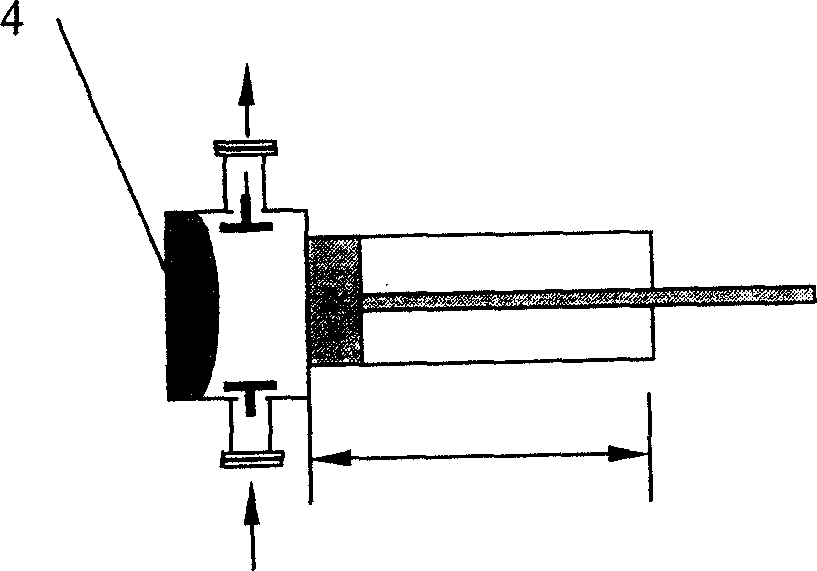

[0045] Embodiment 2: A low-pressure air compressor is connected in series with a modified reciprocating drilling pump to realize high-pressure foam drilling.

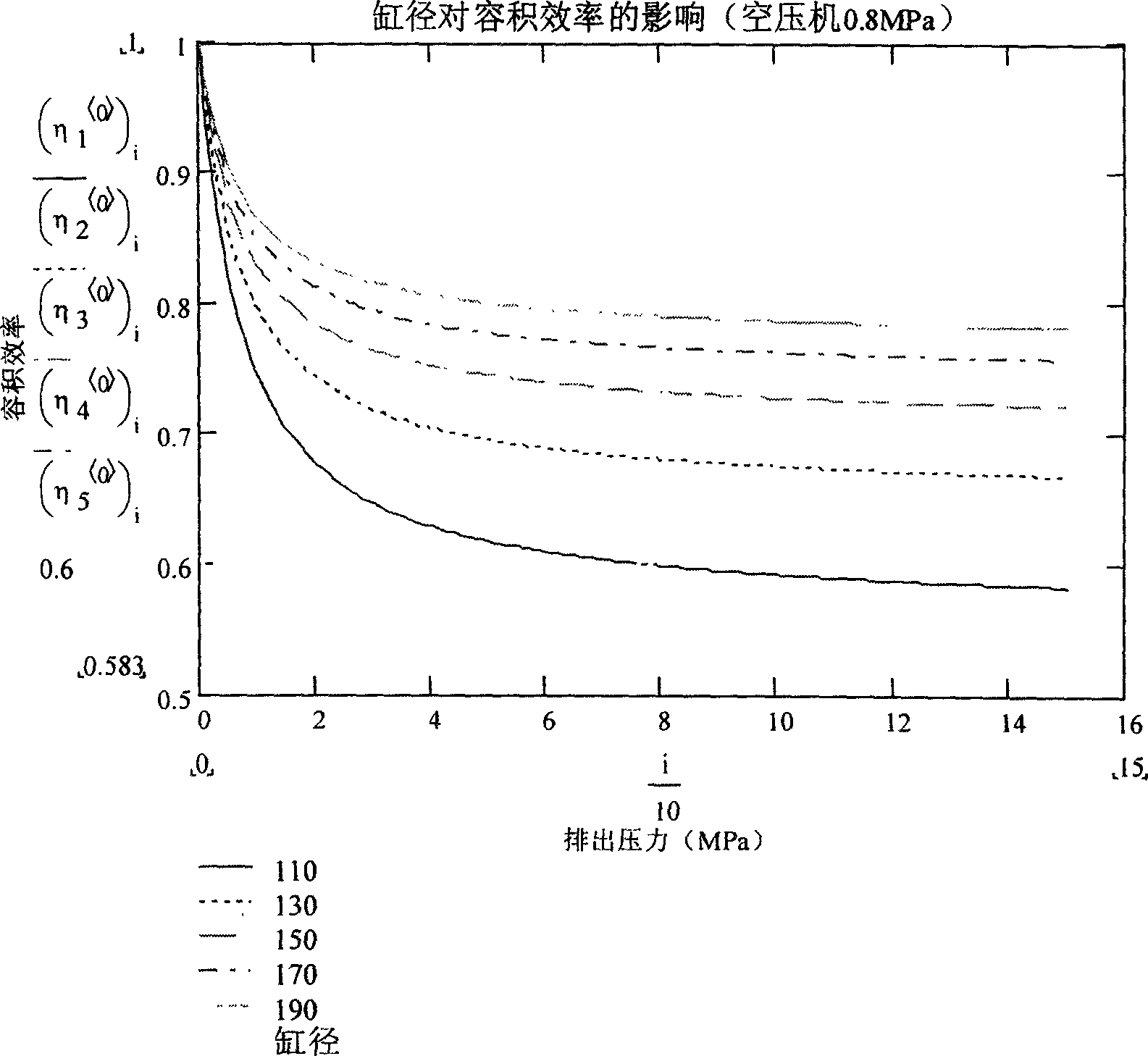

[0046] Such as Figure 7 As shown, the modified reciprocating drilling pump 9 is selected, matched with a low-pressure base fluid pump 13 and a low-pressure air compressor 11 (there are four possibilities of 0.8MPa, 1.2MPa, 1.8MPa, and 2.4MPa) to realize this method.

[0047] Its working process is as follows: the low-pressure air compressor 11 boosts the air and discharges it to the front of the foam generator 14 through the one-way valve, and enters the foam generator 14 together with the foam base liquid 12 discharged through the base liquid pump 13 to mix and foam, and then The foam passes through the modified reciprocating drilling pump 9, and after being compressed, it enters the wellbore 10 through the discharge pipeline, so as to achieve the purpose of using the reciprocating pump to achieve high-pressure foam d...

Embodiment 3

[0048] Example 3: Utilize the modified reciprocating pump to realize ultra-high pressure injection of gas-containing drilling fluid for drilling operations.

[0049] Figure 8 This method is a flow chart of realizing ultra-high pressure foam drilling by using the modified reciprocating pump and high-pressure air compressor in series. Its working process is as follows: After the low-pressure air compressor 11 and the high-pressure air compressor 15 boost the air pressure, they enter the foam generator 14 together with the foam base liquid 12 discharged from the base liquid pump 13 to mix and foam, and then the foam passes through the modified The reciprocating drilling pump 9 enters the wellbore 10 through the discharge pipeline after being compressed, so as to achieve the purpose of ultra-high pressure foam drilling by using the modified reciprocating pump and high-pressure air compressor in series. For the given low and high pressure air compressor pressure, the gas-liquid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com