Hydrostatic pressure auxiliary shoring cutter-holder and shoring method

An auxiliary support, liquid technology, applied in the direction of reamer, boring bar, tool holder accessories, etc., can solve the problems of high use cost, high installation and adjustment requirements of support bars or support blocks, and unsatisfactory support effect, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

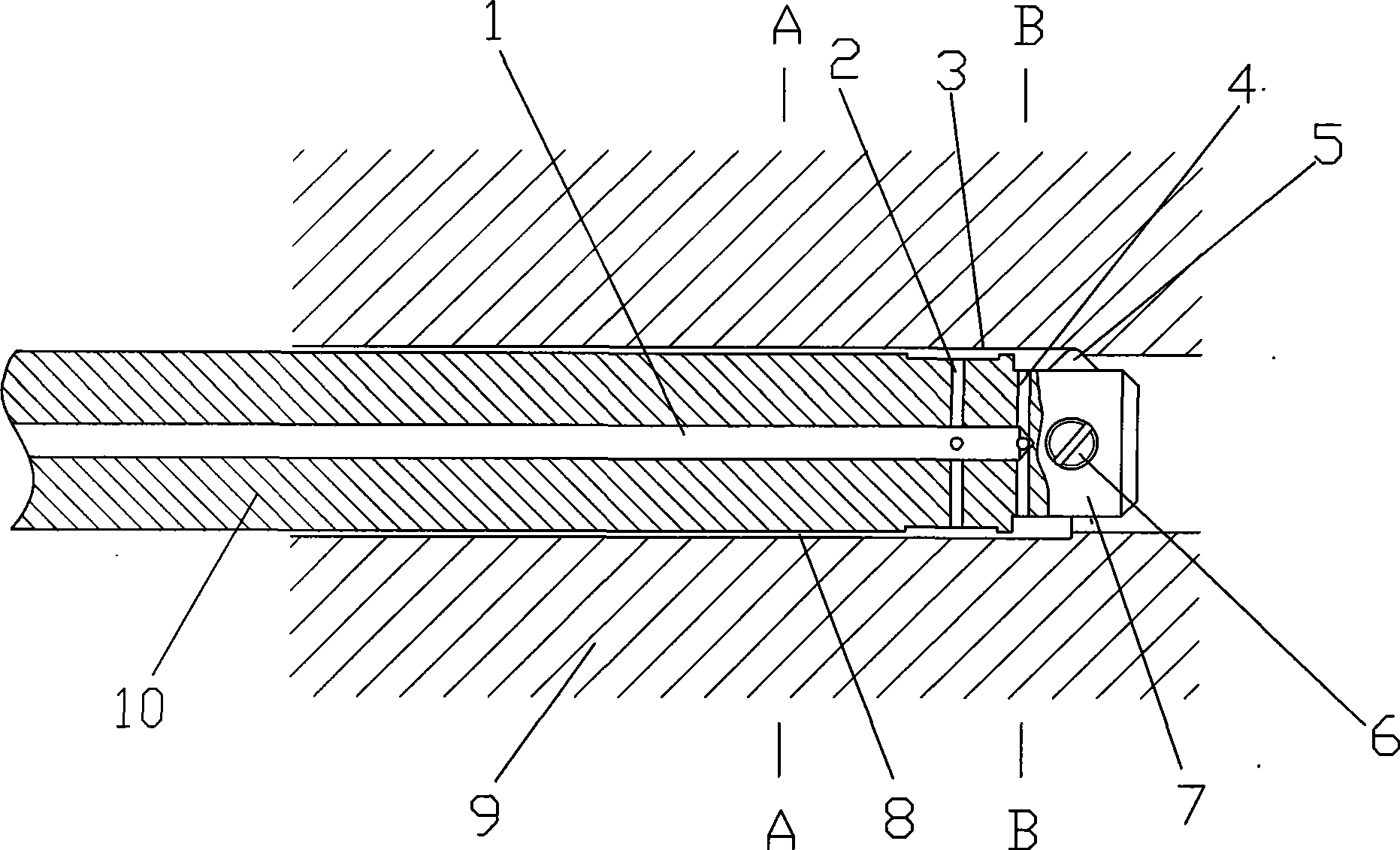

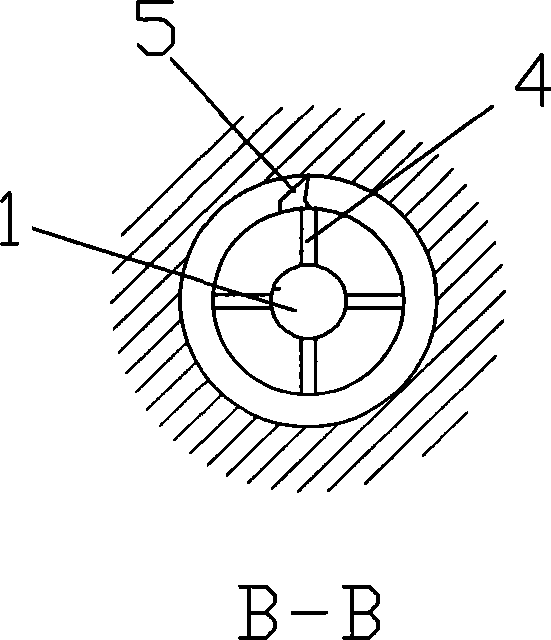

[0016] see figure 1 , the structural form of the tool bar is a rod head 7 for installing the tool 5, a hosel with a cutting fluid flow channel 4 and a shaft 10 as a rod head support. The axial hole in the center of the shaft 10 is set for cutting The liquid supply channel 1 is in communication with the hosel cutting fluid flow channel 4 .

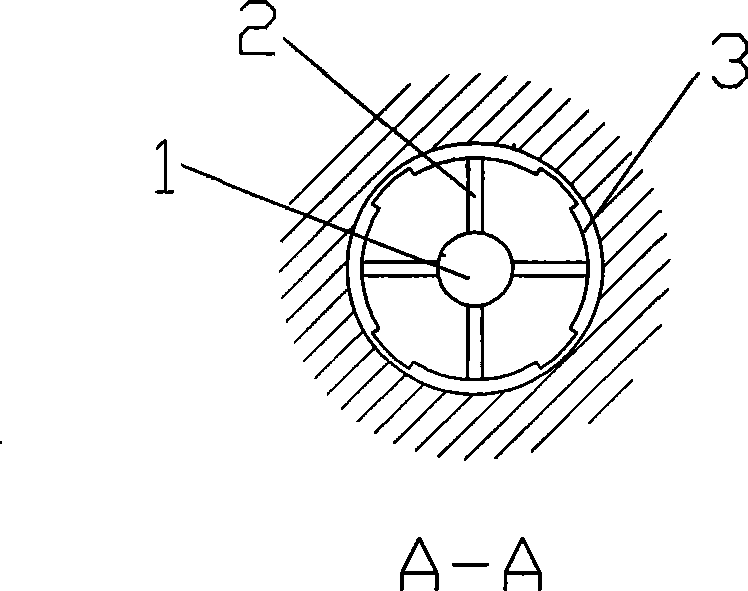

[0017] like figure 1 As shown, in this embodiment, the independent pressure-bearing grooves 3 are evenly distributed on the surface of the shaft 10 and along the outer circumference of the shaft 10, and the liquid supply channel communicates with the pressure-bearing grooves 3 through the small hole throttling channels 2 respectively. .

[0018] The support method is to set the shaft 10 and the machined hole of the workpiece to fit with a small gap, and each pressure-bearing groove 3 on the surface of the shaft and the inner wall of the machined hole of the workpiece form each pressure-bearing cavity, and the cutting fluid supply channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com