Self-adapting variable-damping hydraulic pressure rubber vibration isolation device for automobile suspension

An automobile suspension and self-adaptive technology, applied in the direction of shock absorber, shock absorber-spring combination, spring/shock absorber, etc., can solve problems such as poor damping, poor adaptability, and invariable damping effect. Achieve the effect of preventing damping failure, good use value and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

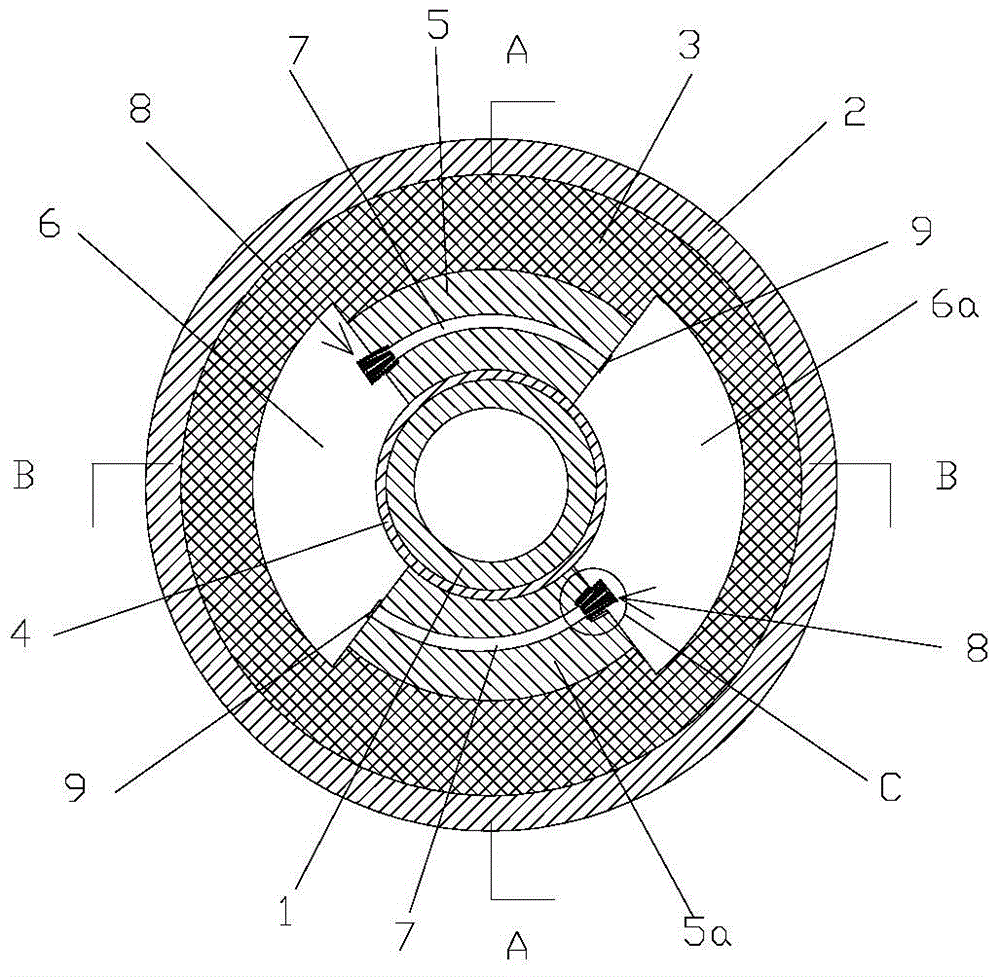

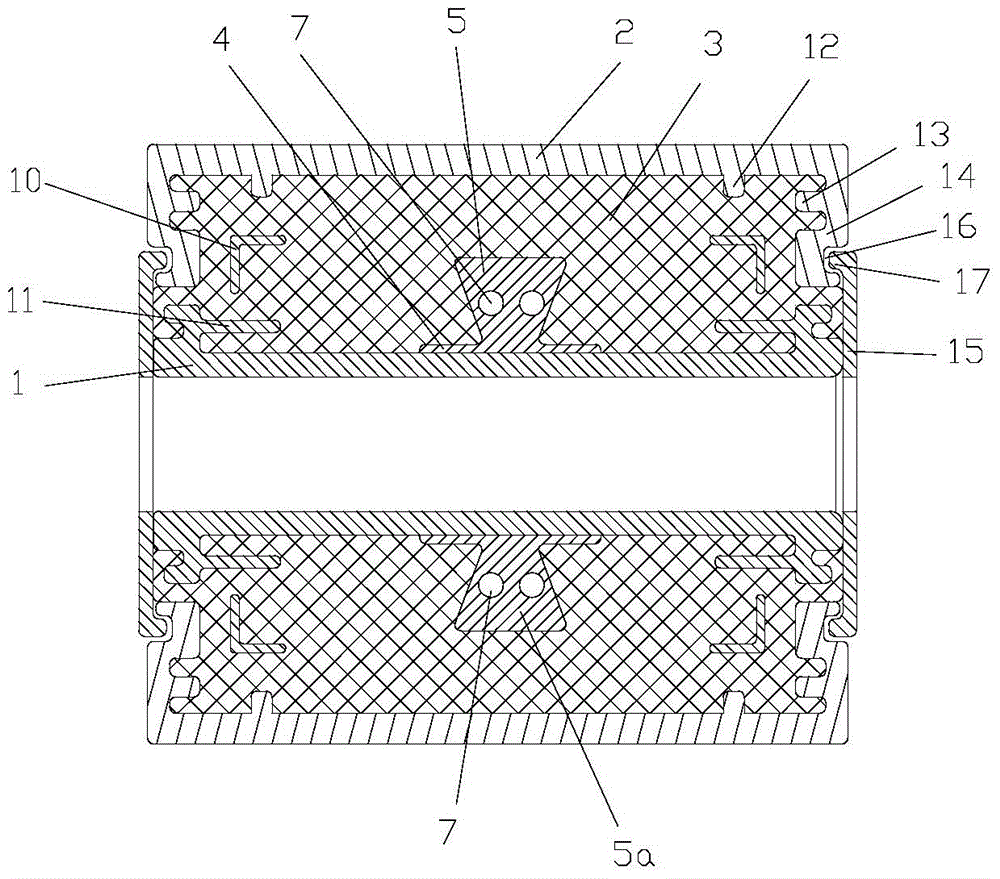

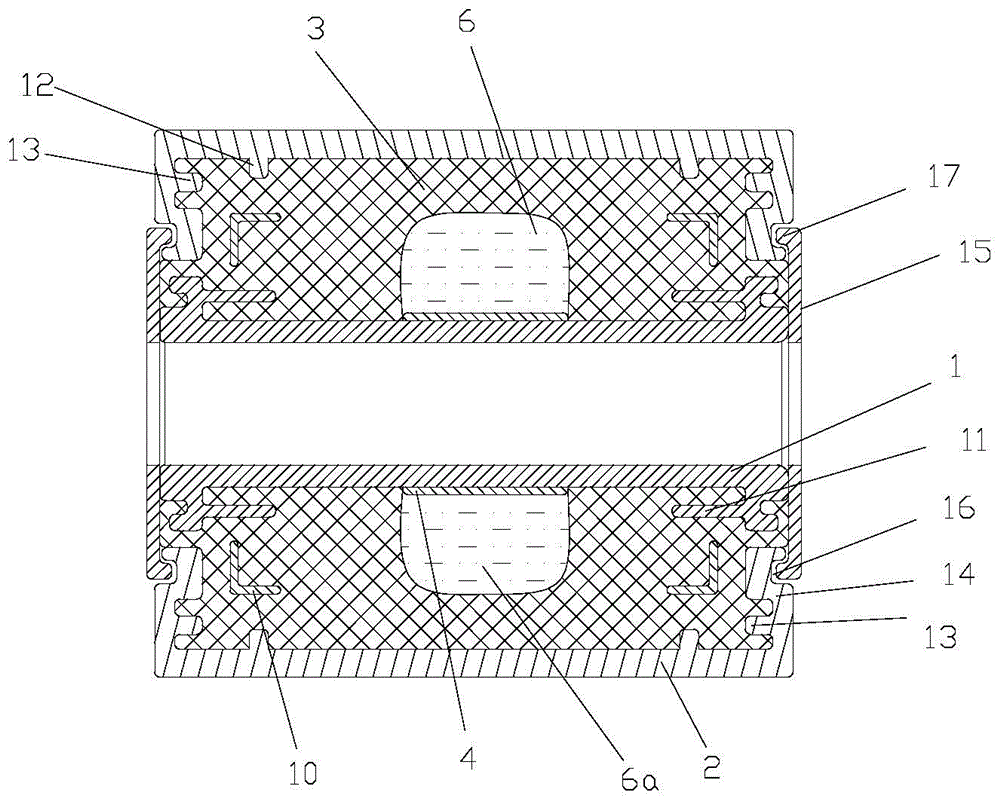

[0022] As shown in the figure: the adaptive variable damping hydraulic rubber vibration isolation device for automobile suspension in this embodiment includes an inner tube 1, an outer tube 2 and a rubber body 3 arranged between the inner tube 1 and the outer tube 2, and It includes a separating device arranged between the inner tube 1 and the rubber body 3. The separating device includes a fixed tube 4 fixed on the periphery of the inner tube 1 and an isolator I5 and an isolator II5a arranged outside the fixed tube 4. The rubber body 3 The space between the fixed pipe 4, the isolation body I5 and the isolation body II5a forms a hydraulic working chamber I6 and a hydraulic working chamber II6a, and the isolation body I5 and the isolation body II5a are respectively provided with a fluid channel 7 for connecting the two hydraulic working chambers;

[0023] The connecting end of the fluid channel 7 of the isolator I5 and the hydraulic working chamber I6 and the connecting end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com