Micro-flow pumping structure, system and manufacturing method

A manufacturing method and pumping technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as poor stability, and achieve high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

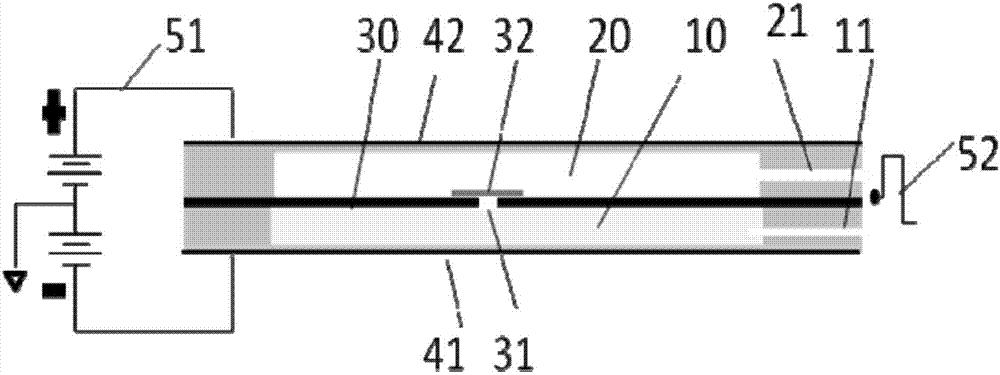

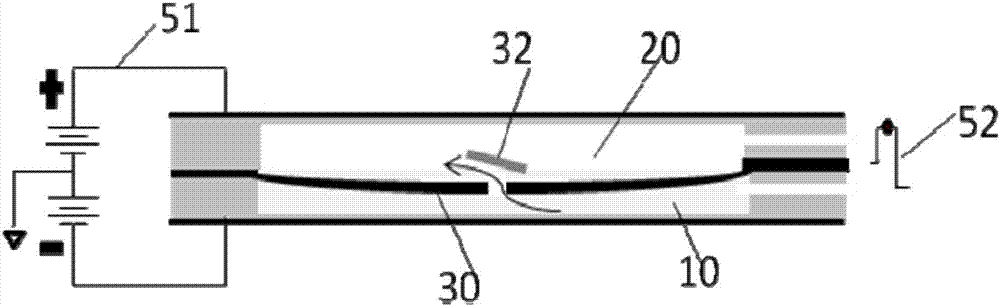

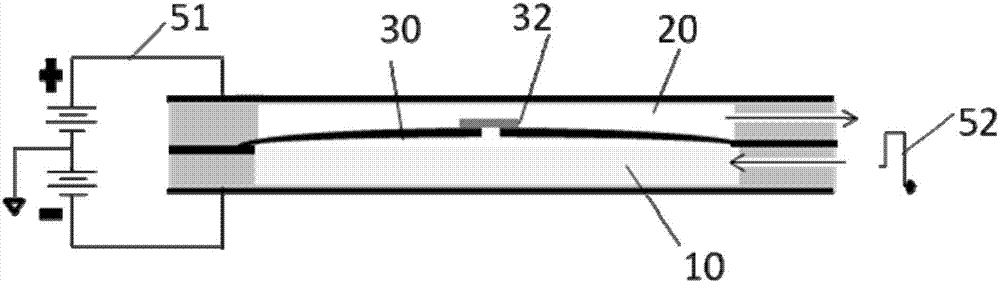

[0028] Such as Figure 7 As shown, a micro-flow pumping structure provided by the first embodiment of the present invention includes: a pump chamber, a power diaphragm 30 disposed in the pump chamber, and a driving device for driving the power diaphragm 30 to move in the pump chamber; The power diaphragm 30 divides the pump cavity into a first chamber 10 and a second chamber 20; the first chamber 10 has a first channel 11 for communicating with the outside, and the second chamber 20 has a channel for communicating with the outside. In the second channel 21 , the power diaphragm 30 has a third channel that opens from the first chamber 10 to the second chamber 20 in one direction. That is to say, the present embodiment divides the pump chamber into a first chamber 10 and a second chamber 20 by setting a power diaphragm 30 in the pump chamber, and the power diaphragm 30 continuously divides the first chamber into the first chamber while moving in the pump chamber. The liquid in ...

Embodiment 2

[0031] Such as Figures 1 to 3 The second embodiment shown is different from the first embodiment in that the power diaphragm 30 is driven by electric field force in the second embodiment. Specifically, the micro-flow pumping structure also includes two conductive plates arranged on both sides of the pump chamber and opposite to the dynamic diaphragm 30. The dynamic diaphragm 30 is a conductor, even if the dynamic diaphragm 30 is located on the two conductive plates. in the electric field. The driving device includes a DC power supply 51 applied to one of the two conductive plates and the dynamic diaphragm 30 , and an AC power supply 52 applied to the other of the two conductive plates and the dynamic diaphragm 30 . Preferably, two conductive plates form the two side walls of the pump chamber, i.e. Figures 1 to 3 On the one hand, the upper and lower side walls can reduce the thickness of the entire micro-flow pumping structure; on the other hand, it can also reduce the proc...

Embodiment 3

[0039] Such as Figure 7 As shown, in the third embodiment of the present invention, the difference from the first embodiment is that the power diaphragm 30 is driven by electromagnetic force in the third embodiment. Specifically, the power diaphragm 30 is provided with ferromagnetic material or magnetic material, and the driving device is an electromagnet arranged outside the pump chamber. By controlling the magnetic force of the electromagnet, the driving of the power diaphragm 30 is realized, and then the liquid pumping is realized. The specific pumping process is similar to the first and second embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com