Mechanically variable and continuously variable type dual-purpose gearbox for crawler-type tractor

A technology of stepless transmission and tractors, applied in mechanical equipment, belts/chains/gears, fluid transmission devices, etc., to achieve the effects of reducing oil consumption, reducing failure rates, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

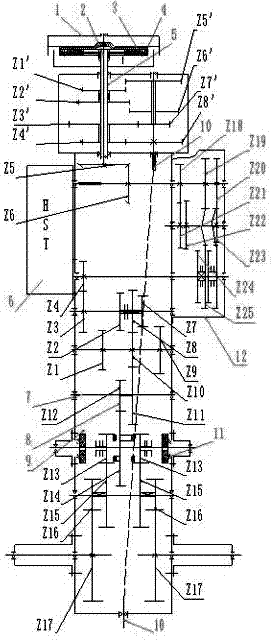

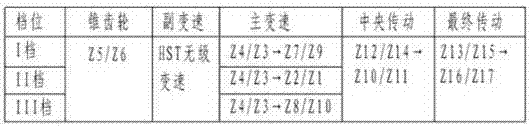

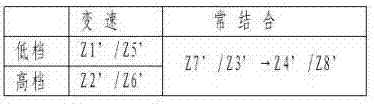

[0024] The present invention is a crawler tractor CVT that adopts the direct connection mode with the power machine, and the power is transmitted to the I-gear driving gear Z1' / I-gear driven gear Z5'→transmission gear CZ7' through the clutch and the hollow transmission shaft 5 / Transmission gear AZ3'→transmission gear BZ4' / transmission gear DZ8'→power output shaft 10; or the power is transmitted to II gear driving gear Z2' / II gear driven gear Z6'→transmission gear by hollow transmission shaft 5 through the clutch CZ7' / transmission gear AZ3'→transmission gear BZ4' / transmission gear DZ8'→power output shaft 10; two speeds are provided for the power output shaft 10.

Embodiment 2

[0026] The transmission force of the continuously variable walking transmission is transmitted from the solid transmission shaft 2 to the transmission gear eZ5 / transmission gear fZ6→hydrostatic continuously variable transmission (HST)6→transmission gear dZ4 / transmission gear cZ3→transmission gear gZ7 / transmission gear iZ9( Or transmission gear bZ2 / transmission gear aZ1, or transmission gear hZ8 / transmission gear jZ10) →Z10 transmission gear j / Z11 transmission gear k→transmission gear lZ12 / central transmission gear Z14→steering gear Z13 / transmission gear mZ15→transmission gear nZ16 / Transmission gear oZ17→drive shaft.

Embodiment 3

[0028]The power of the mechanical variable speed walking transmission is transmitted from the solid shaft 2 to the transmission gear eZ5 / transmission gear fZ6→reverse transmission gear pZ18 / transmission gear sZ21→transmission gear tZ22 / transmission gear vZ24 (high-grade transmission gear qZ19 / transmission gear wZ25, low-speed transmission gear pZ18 / transmission gear sZ21→transmission gear uZ23 / transmission gear rZ20→transmission gear rZ20 / transmission gear wZ25)→transmission gear dZ4 / transmission gear cZ3→transmission gear gZ7 / transmission gear iZ9 (or transmission gear bZ2 / transmission gear aZ1, or transmission Gear hZ8 / transmission gear jZ10)→Z10 transmission gear j / Z11 transmission gear k→transmission gear lZ12 / central transmission gear Z14→steering gear Z13 / transmission gear mZ15→transmission gear nZ16 / transmission gear oZ17→drive shaft.

[0029] Between the central transmission gear Z14 and the steering gears Z13 on both sides, there is a tooth for steering. By turning the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com