Blockage-proof central fire cover and combustor adopting central fire cover

A central fire cover and anti-clogging technology, which is applied in the field of burner components, can solve problems such as clogging, and achieve the effects of improving thermal efficiency, cooling speed, and reducing smoke and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

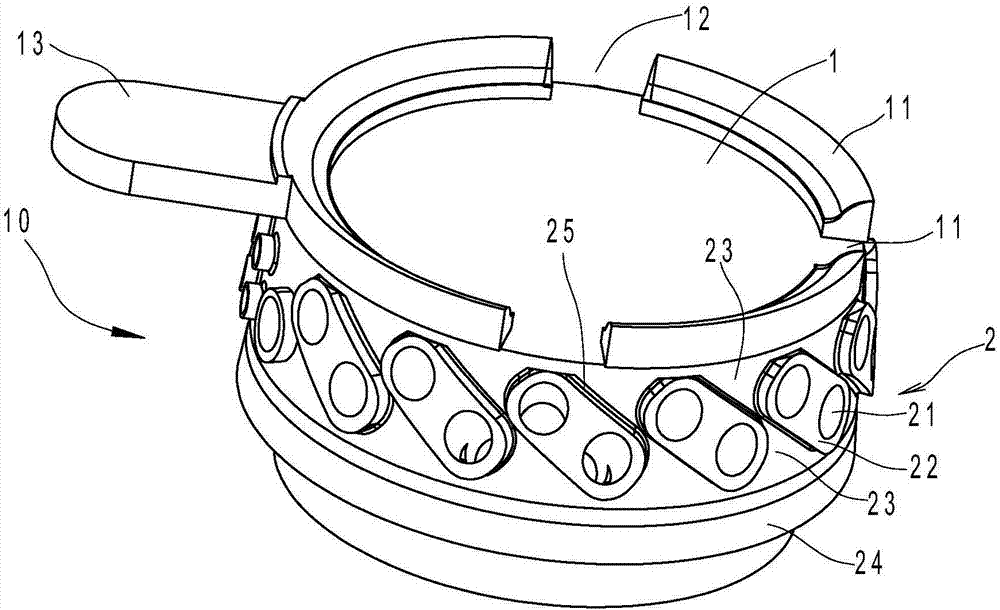

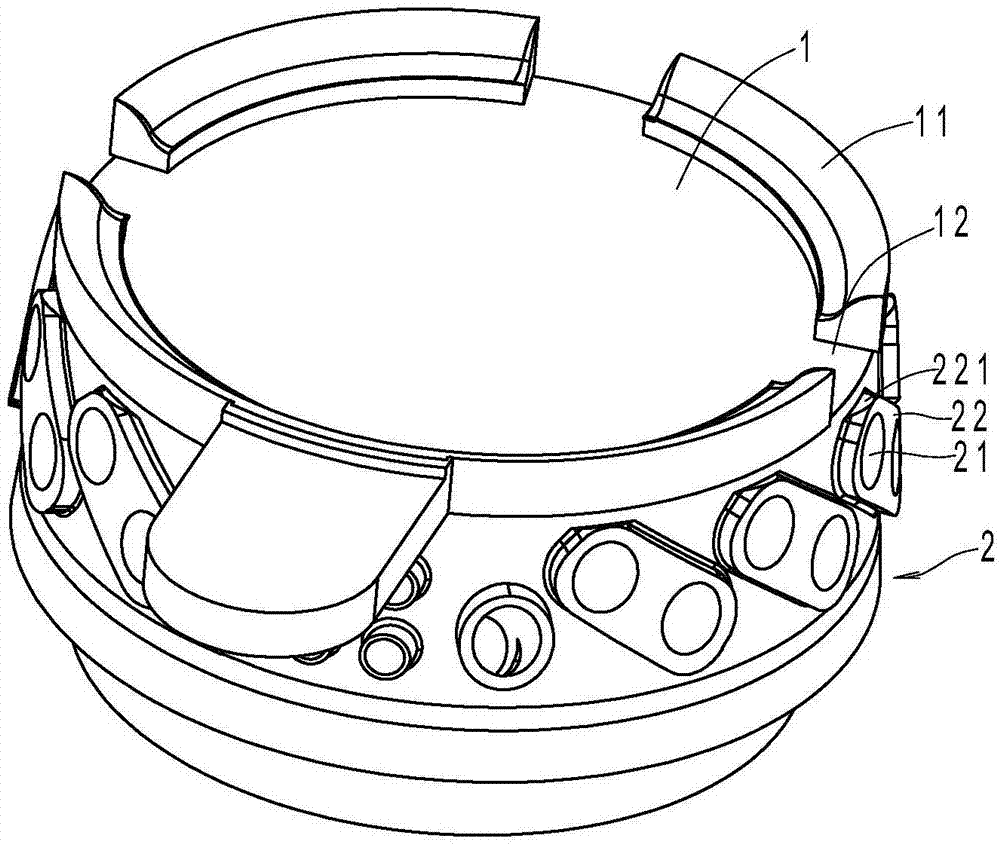

[0030] Example 1, as figure 1 and figure 2 As shown, the anti-clogging central fire cover in this embodiment includes a cylinder body 2 and an end cap 1 integrally formed on the cylinder body 2. The peripheral wall of the cylinder body 2 is provided with a fire hole 21, and one side of the end cap 1 is formed to cover the ignition The protective cover 13 of the needle 32, the top surface of the end cap 1 is raised in the middle and inclined radially to the periphery (refer to image 3 shown), the top surface of the end cap 1 has a retaining ring 11 around the edge to limit the overflow of the overflowing liquid, and the inner side of the retaining ring 11 has an inwardly inclined flow guiding end surface. The retaining ring 11 is provided with three drainage openings 12 for guiding the overflow liquid to flow out of the end cap 1, and the drainage openings 12 are arranged at intervals. The outer surface of the edge 22 forms a guide surface 25 capable of receiving the overfl...

Embodiment 2

[0039] Example 2, as Figure 5 As shown, in this embodiment, one of the upper fire holes is opened on one flange 22 alone, the guide surface 25 is located on the outer periphery of the flange, and the other upper fire hole and the adjacent two lower fire holes are opened on the same flange 22 , the guide surfaces 25 are located on both sides of the flange. For other structures, refer to Example 1.

Embodiment 3

[0040] Example 3, as Image 6 As shown, the single fire hole 21 in this embodiment is independently opened on one flange 22, and the flow guide surface 25 is located on the outer periphery of the flange. For other structures, refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com