Stored cargo management method

A management method and warehousing technology, applied in the field of warehousing management, can solve problems such as increased overhead, difficulty in modification, difficulty in ensuring transactional performance, etc., and achieve the effect of simplifying login and frequent and simplified authorization changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

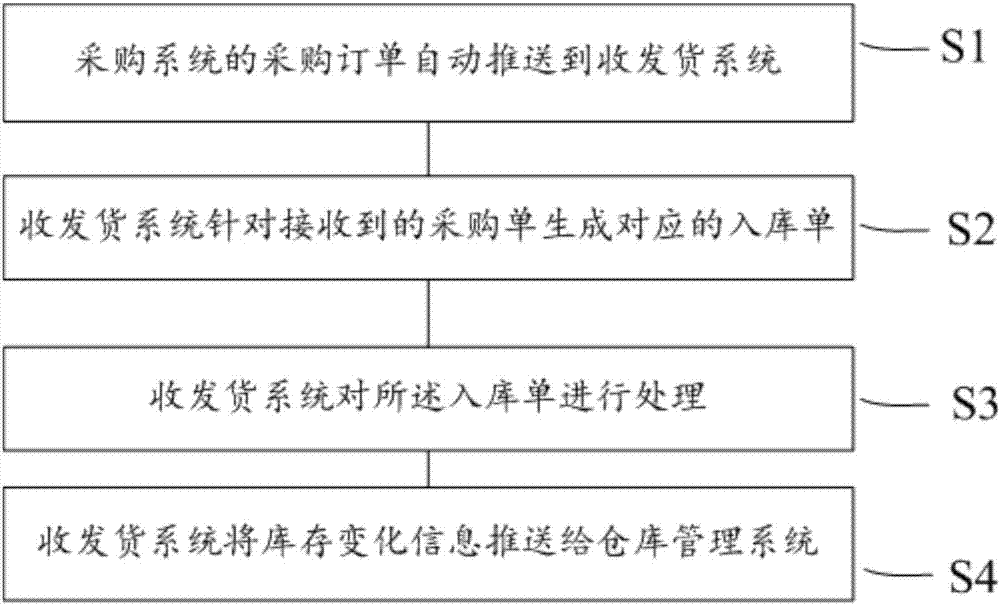

[0034] figure 1 It schematically shows the flow chart of the storage goods management method according to the preferred embodiment of the present invention.

[0035] Specifically, such as figure 1 As shown, the storage goods management method according to the preferred embodiment of the present invention includes:

[0036] The first step S1: the purchase order of the procurement system is automatically pushed to the receiving and shipping system; specifically, the purchase order created by the purchasing system is pushed to the receiving and shipping system through the interface.

[0037] Second step S2: the receiving and shipping system generates a corresponding storage order for the received purchase order;

[0038] The third step S3: the receiving and shipping system processes the storage order;

[0039] For example, PDA handheld data collection can be used for on-site verification and entry. Through the PDA’s built-in shelf application, the receiver can hold the PDA to ...

no. 2 example

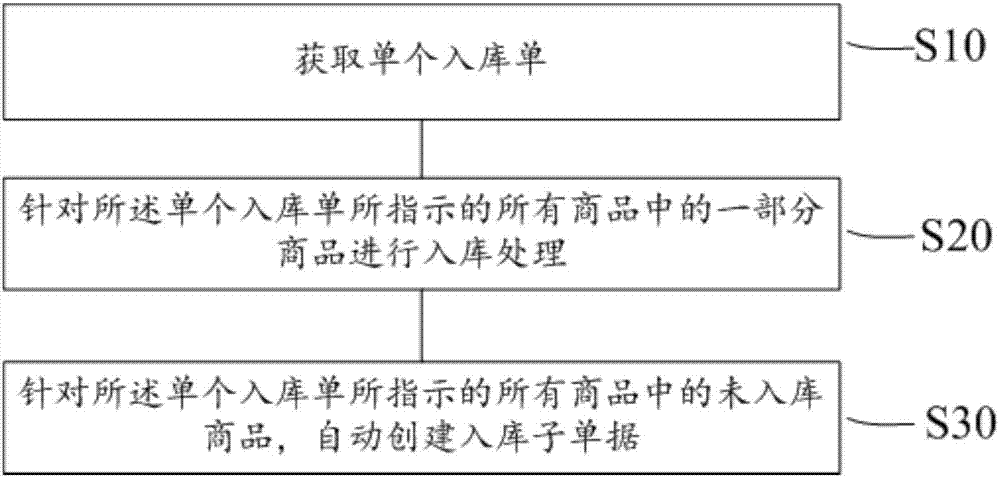

[0046] The second embodiment illustrates an example of the processing flow for multiple receipts of a single delivery batch when the receiving and delivery system proposed by the present invention processes the storage order.

[0047] figure 2 It schematically shows a flow chart of the processing flow of multiple receipts of a single delivery batch according to a preferred embodiment of the present invention.

[0048] Such as figure 2 As shown, according to the preferred embodiment of the present invention, the processing flow for multiple receipts of a single delivery batch includes:

[0049] The first storage step S10: obtaining a single storage order;

[0050] For example, obtaining a single storage order includes: receiving a single storage order or generating a single storage order for a goods document (for example, a purchase order).

[0051] More specifically, for example, warehouse receipts are automatically generated through upstream systems such as purchase requ...

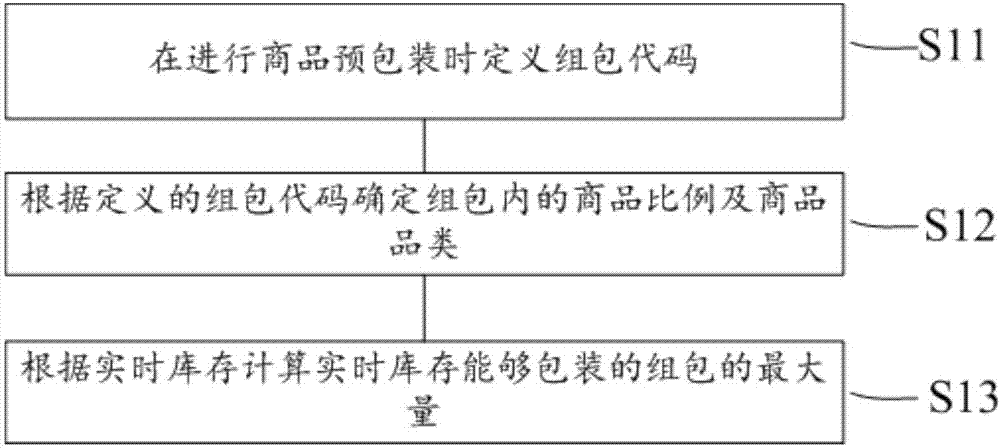

no. 3 example

[0064] In specific applications, for example, for the transfer of goods in the same cost center between different warehouses, the transfer order is created and the warehouse-out and storage orders of the corresponding warehouses are automatically created, so that the above-mentioned processing flow can be carried out during the transfer.

[0065] Specifically, the warehouse transfer management method according to the preferred embodiment of the present invention may include the following steps:

[0066] Create an outbound order for the first warehouse and an inbound order for the second warehouse, wherein the outbound order corresponds to the inbound order; for example, the outbound order indicates that 1,000 specific commodities are put into storage A stock-out slip, the stock-in slip is a stock-in slip indicating that 1,000 pieces of specific commodities are put into storage.

[0067] The first warehouse sends all the commodities in the first warehouse that satisfy the deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com