Stamping die

A technology of stamping dies and dies, which is applied in the direction of perforating tools, manufacturing tools, metal processing equipment, etc., can solve the problems of warping at both ends of the workpiece, and achieve the effect of avoiding turbine rotation, good effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

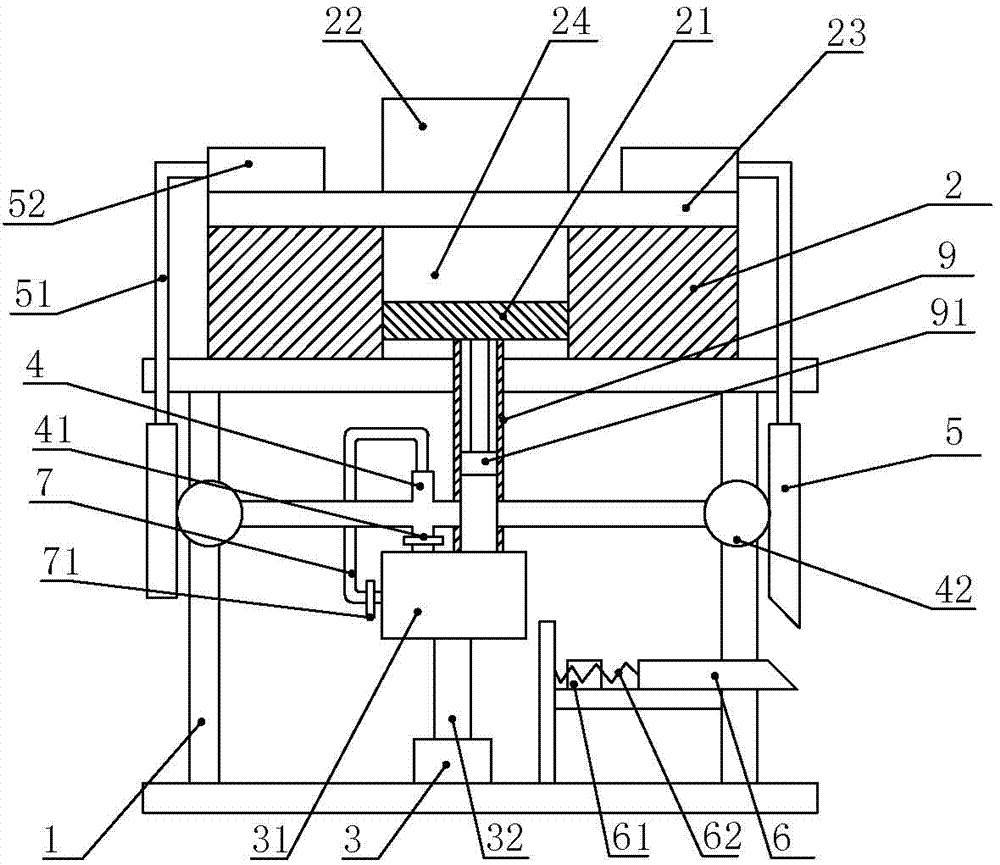

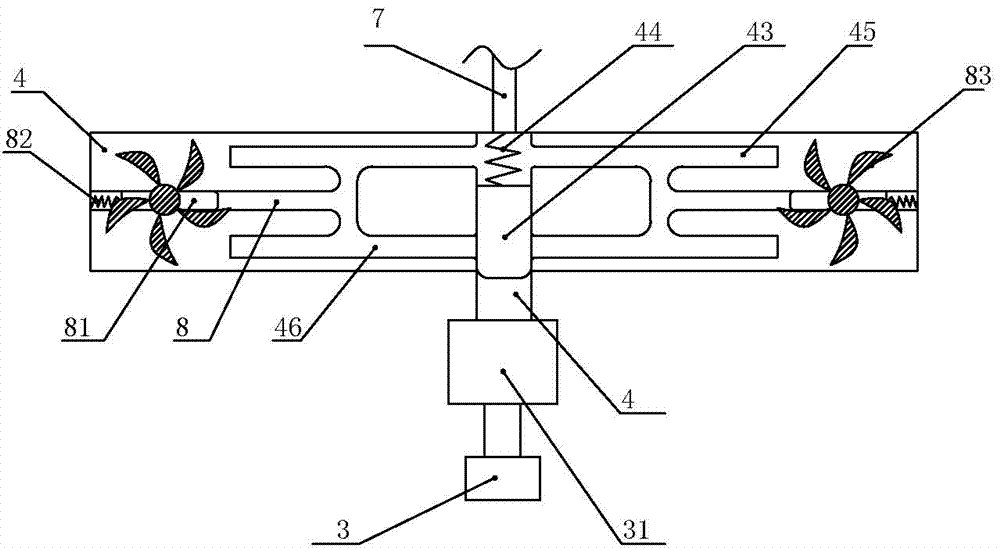

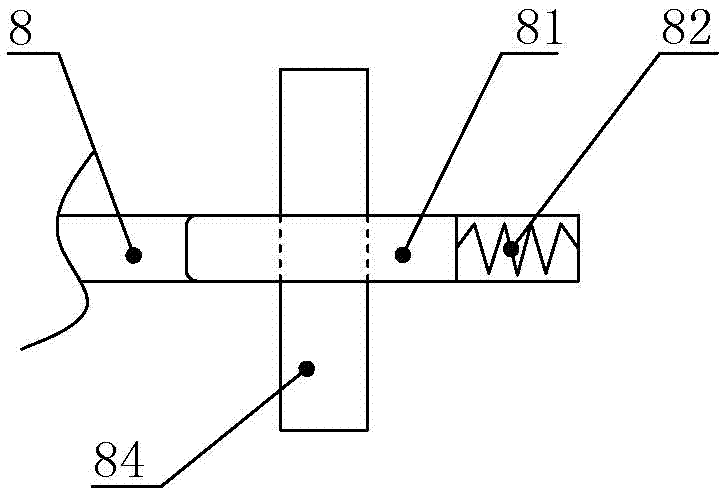

[0023] The reference signs in the drawings of the description include: frame 1, upper mold 2, lower mold 21, punch 22, workpiece 23, mold cavity 24, steam generator 3, booster pump 31, air pipe 32, main pipe 4, the first A valve 41, a gear 42, a slide plate 43, a first spring 44, a first air passage 45, a second air passage 46, a rack 5, a connecting rod 51, a pressing block 52, a wedge bar 6, a switch 61, and a third spring 62 , branch pipe 7, second valve 71, third air passage 8, latch 81, second spring 82, turbine 83, turbine shaft 84, conduit 9, slide block 91.

[0024] The embodiment is basically as shown in the accompanying drawings

[0025] Such as figure 1 As shown, a stamping die of the present invention includes a frame 1, an upper mold 2 is arranged on the frame 1, a mold cavity 24 is opened in the middle of the upper mold 2, and a lower mold 21 is slidably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com