Anti-overflow control method of soybean milk machine

A control method and anti-overflow technology, which is applied in home appliances, applications, kitchen appliances, etc., can solve the problems of high heat generation, high speed, large load, etc., and achieve a reliable effect of the control scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

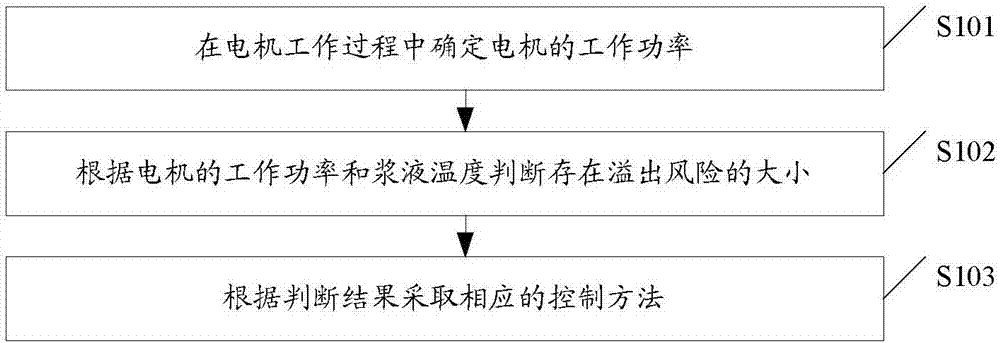

[0066] A kind of anti-overflow control method of soybean milk machine, such as image 3 As shown, the method may include S101-S103:

[0067] S101. Determine the working power of the motor during the working process of the motor.

[0068] In the embodiment of the present invention, due to the many functions of the soybean milk machine, the recipes of different functions are quite different, the load difference of the motor during the beating process is also large, the working power of the motor is also large, and the heat generated is also large. The moment when the slurry temperature reaches a certain limit during the working process of the motor is also different. Therefore, it is necessary to monitor the working power of the motor during the working process of the motor to judge the risk of overflow according to the working power, so as to intelligently adjust the subsequent pulping process. Avoid overflow during the beating process.

[0069] In the embodiment of the prese...

Embodiment 2

[0103] The difference between this embodiment and the first embodiment is that another embodiment for judging the overflow risk is provided.

[0104] In the embodiment of the present invention, the change rate threshold value ΔV of the potential value of the temperature signal during the beating process can be preset. Accuracy and stability of temperature detection during beating process. Specifically, it can be realized through the following scheme.

[0105]Optionally, judging the degree of overflow risk based on the working power of the motor may also include:

[0106] calculating the slurry temperature change rate according to the detected slurry temperature and a preset first temperature threshold; and when the detected slurry temperature is greater than the first temperature threshold, updating the first temperature threshold with the detected slurry temperature;

[0107] When the slurry temperature change rate calculated for several times in succession is less than the...

Embodiment 3

[0112] This embodiment can intelligently identify the current working condition of the motor by detecting the number k of high-power beating temperature rises in the pulping process on the basis of the first or second embodiment.

[0113] Optionally, the method may also include:

[0114] counting the number of times the detected slurry temperature meets the second preset condition;

[0115] When the counted times meet the preset first count range, it is judged that the motor is currently in normal working state; when the counted counts meet the preset second count range, it is judged that the motor is currently in an overload working state; When the number of output times meets the preset third number range, it is determined that the motor is currently in a state of degraded performance;

[0116] Wherein, the number of times included in the range of the first number is less than the number of times included in the range of the second number; the number of times included in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com