Lifting device for infiltration tank workpiece basket

A technology of lifting device and workpiece basket, which is applied to the device and coating of the surface coating liquid, which can solve the problems of vacuum loss of impregnation tank, loss of vacuum effect, reduction of impregnation pass rate, etc., and achieve impregnation qualified The effect of increasing the rate, improving the efficiency and shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

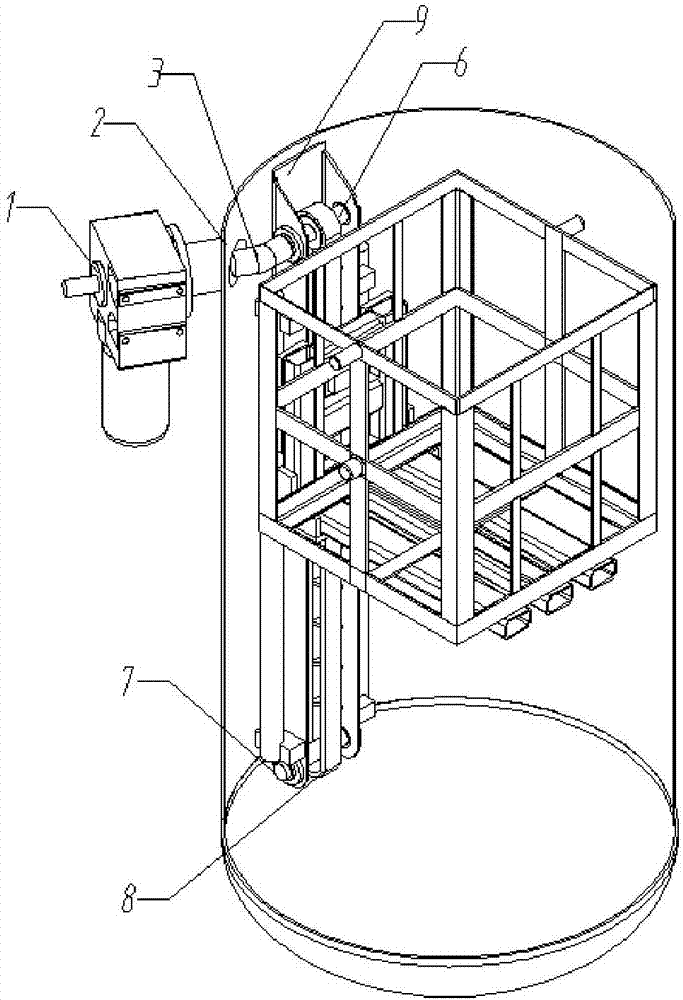

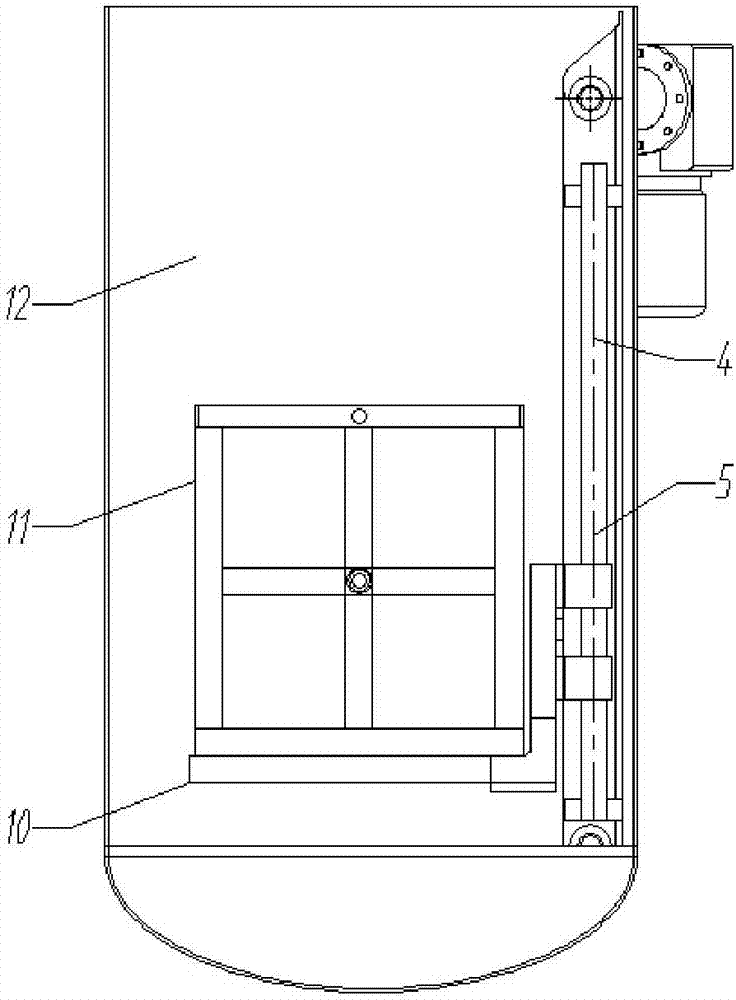

[0011] The structure of the lifting device of the impregnation tank workpiece basket of the present invention will be described in conjunction with the accompanying drawings.

[0012] like figure 1 , 2 As shown, the structure of the lifting device of the impregnation tank workpiece basket of the present invention is that the device includes a motor reducer 1, a mechanical rotary seal 2, a universal coupling 3, a guide rod 4, a guide sleeve 5, and a driving sprocket 6 , driven sprocket 7, chain 8, chain transmission support frame 9, workpiece basket lifting support frame 10, workpiece basket 11, soaking tank body 12; the universal coupling 3 is arranged on the soaking tank body 12 On the upper part of the inner wall, the motor reducer 1 is set outside the impregnation tank and connected with the universal coupling 3 through the mechanical rotary seal 2, the universal coupling 3 is connected with the driving sprocket 6, and the driving sprocket 6 passes through the chain 8 Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com