A single tank washing machine

A cleaning machine and single-tank technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of frequent replacement of cleaning liquids, high cleaning costs, and high labor costs, and reduce labor costs. Cost and labor intensity, improve cleaning degree, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

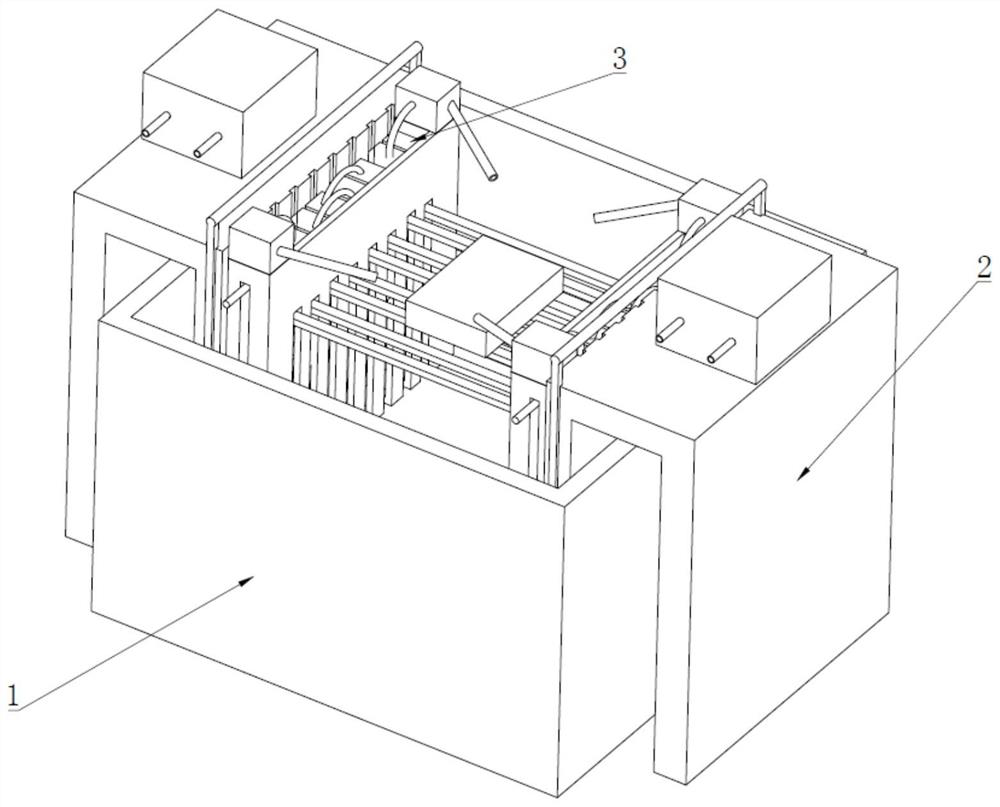

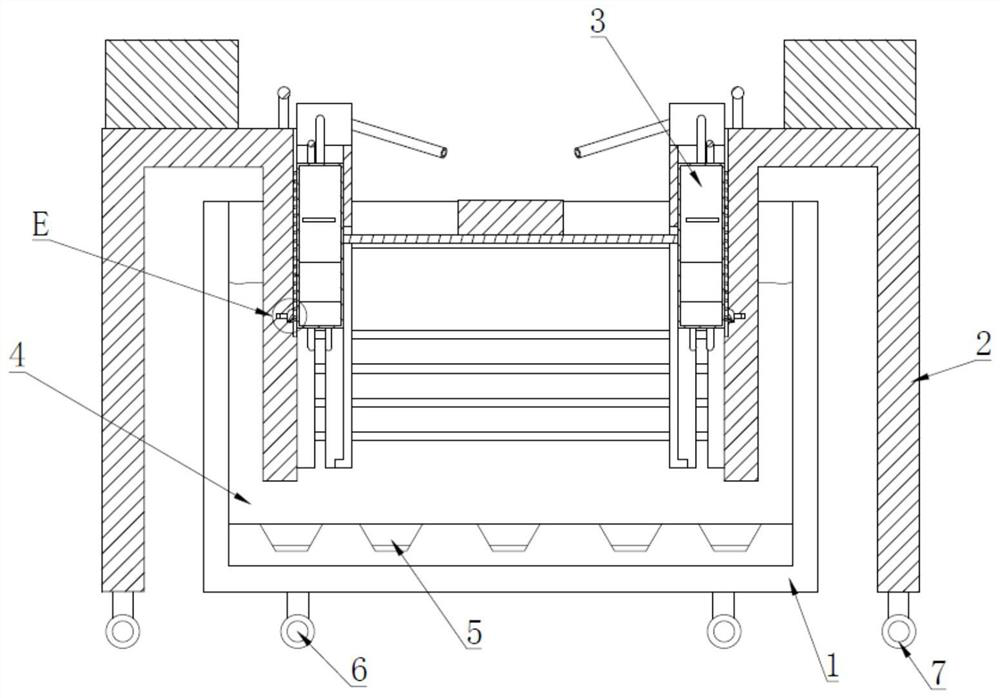

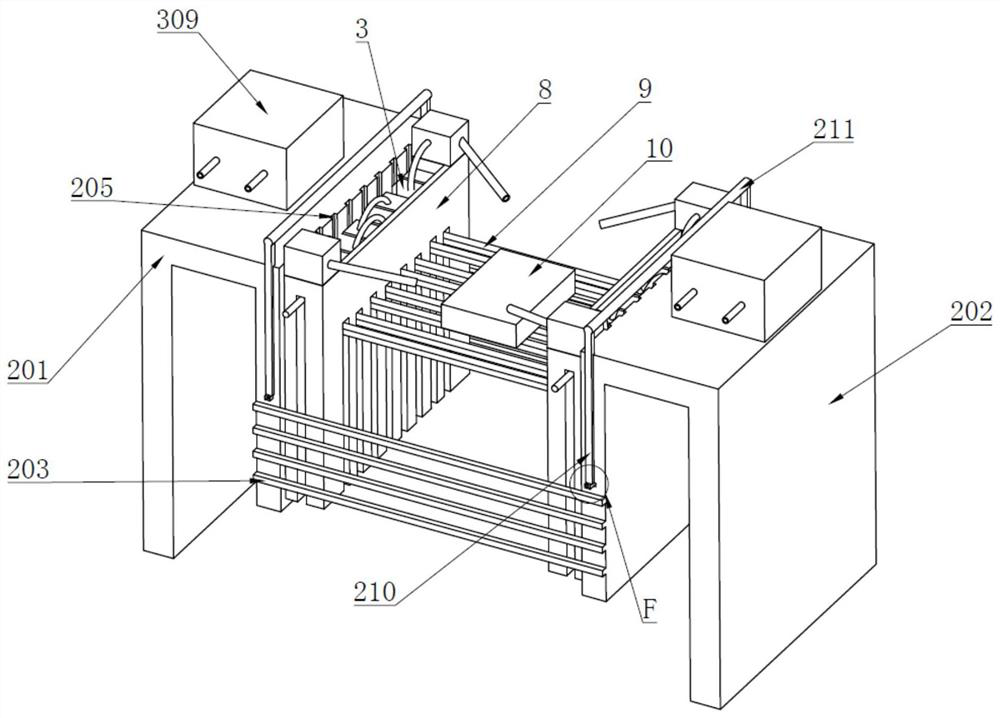

[0030] The present invention provides a single-slot cleaning machine as shown in the figure. A single-slot cleaning machine includes a cleaning tank, a cleaning base, and a lifting filter device, wherein:

[0031]Specifically, cleaning solution 4 is installed inside the cleaning tank 1, an ultrasonic transducer 5 is installed at the bottom of the cleaning tank 1, a roller-6 is installed at the bottom of the cleaning tank 1, and the ultrasonic transducer 5 is externally connected with Ultrasonic power supply, the cleaning base 2 is a left base 201 and a right base 202, the left base 201 and the right base 202 are "n" shaped, the right part of the left base 201 and the right The left part of the base 202 is located inside the cleaning tank 1, the bottom of the cleaning base 2 is equipped with two rollers 7, and the left base 201 and the right base 202 are fixedly connected by evenly distributed connecting rods 203 , the right side of the left base 201 is provided with a lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com