Secondary defoaming device and secondary defoaming method

A defoaming device and air bubble technology, which is applied in the direction of lamination devices, chemical instruments and methods, layered products, etc., can solve the problems of loss of sensor cover plate, bad air bubbles, etc., so as to avoid dismantling loss of materials and reduce bad air bubbles Proportion, the effect of avoiding insufficient shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

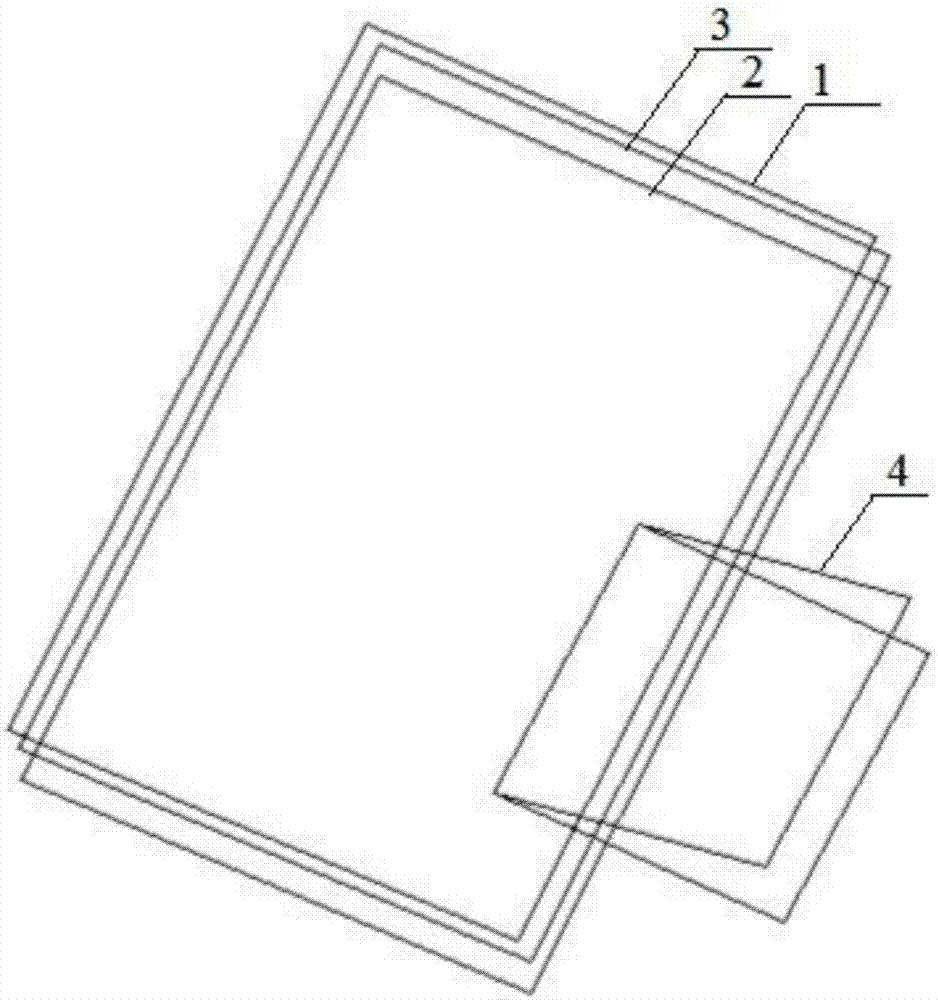

[0021] Example 1, such as figure 1 As shown, a secondary defoaming device according to the first embodiment of the present invention includes: a first cover 1 arranged above the front of the touch product 3 , a second cover 2 arranged below the back of the touch product 3 and a clip 4 for clamping the first cover plate 1 and the second cover plate 2;

[0022] Clip 4 consists of an upper clip and a lower clip, one end of the upper clip is flexibly connected to one end of the lower clip, the other end of the upper clip is clamped on the upper surface of the first cover plate 1, and the other end of the lower clip is clamped The lower surface of the second cover plate 2 .

[0023] Further, in order to protect the cover from being pinched, the cover can be reused later, the upper clamp is provided with a rubber pad on the side close to the first cover 1, and the lower clamp is on the side close to the second cover 2 Features rubber pads. At the same time, in order to ensure the...

Embodiment 2

[0025] Embodiment 2, a kind of secondary defoaming method of the second embodiment of the present invention, this method comprises the following steps:

[0026] Step 1, determine the bubble position of the touch product 3;

[0027] Step 2. Align the clip 4 with the position of the point-shaped bubble or the edge bubble of the touch product 3. The upper splint of the clip 4 clamps the upper surface of the first cover 1, and the lower splint of the clip 4 clamps the lower surface of the second cover 2. Surface, so that the clip 4 clamps the point-like bubbles or edge bubbles of the touch product 3;

[0028] Step 3, placing the entire secondary defoaming device in a defoaming machine to heat and pressurize for secondary defoaming to eliminate air bubbles;

[0029] Step 4, take out the entire secondary defoaming device from the defoaming machine, and take out the touch product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com