Environmental protection transformer with lost wax method potting epoxy resin and preparation method thereof

A technology of epoxy resin and epoxy resin layer is applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor shell, transformer/inductor parts, etc., which can solve the problem of huge labor cost, unfavorable transformer installation, and easy Problems such as deformation occur, to achieve the effect of saving development costs, saving material costs, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

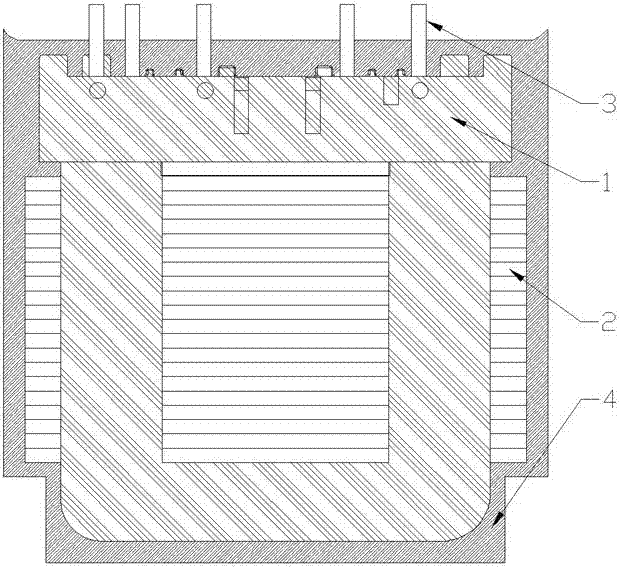

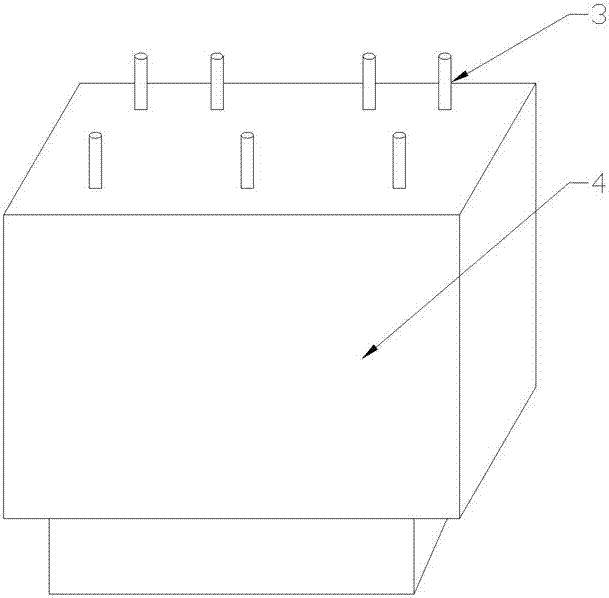

[0024] Such as figure 1 and figure 2 As shown, in the present invention, the environmental protection transformer includes a transformer body, and the transformer body is composed of a skeleton 1, a finished coil wound on the skeleton 1 and a silicon steel sheet 2 sleeved on the skeleton 1. Several connection pins 3 are arranged on the upper end surface of the frame 1 . A layer of integrally formed epoxy resin layer 4 is covered around the entire periphery of the transformer body, and above the skeleton 1 , the connection pins 3 are exposed on the epoxy resin layer 4 . The epoxy resin layer 4 is covered on the periphery of the transformer body by potting.

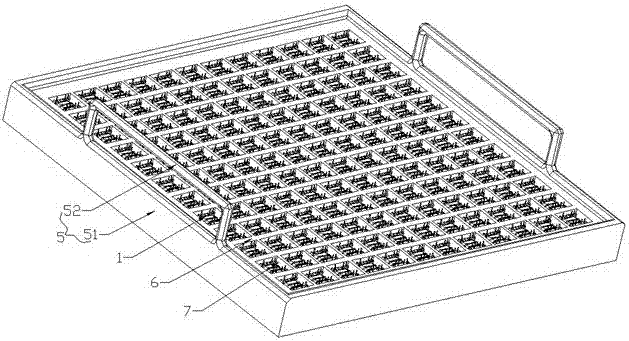

[0025] Such as image 3 and Figure 4 Shown, when preparing above-mentioned transformer, its steps are as follows:

[0026] a. Prefabricated wax mold: Add fluid high temperature resistant paraffin into the transformer tray 5, and after solidification, set a mold cavity 7 matching the transformer body in the formed hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com