A squeeze roller for wet etching

A technology of wet etching and roller, which is applied in the direction of sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc. It can solve the problems of easy abrasion of squeeze rollers, easy pollution of silicon wafer surface, and many defective products. Achieve the effects of saving production costs, not easy to absorb impurities, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

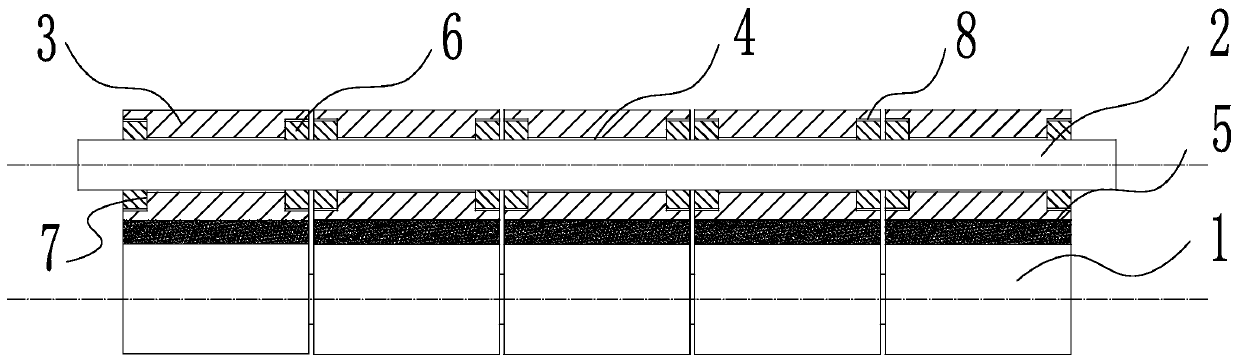

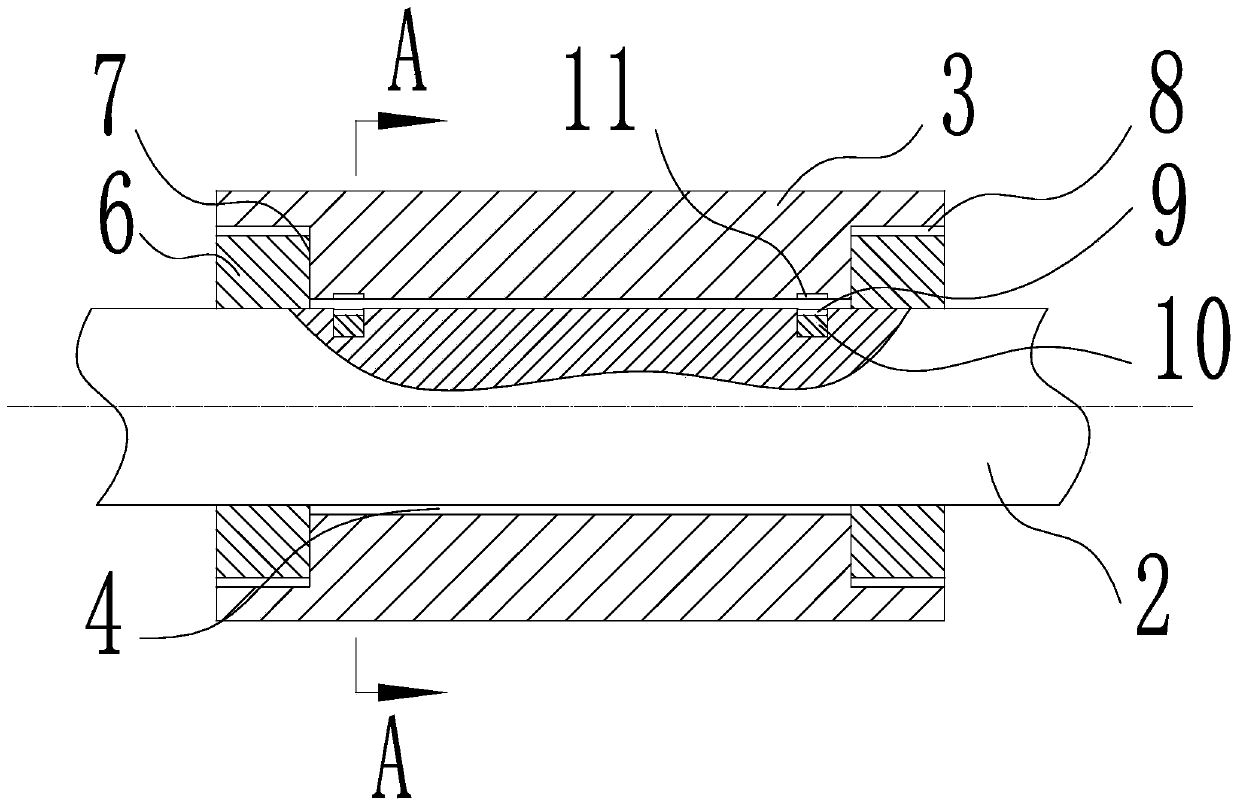

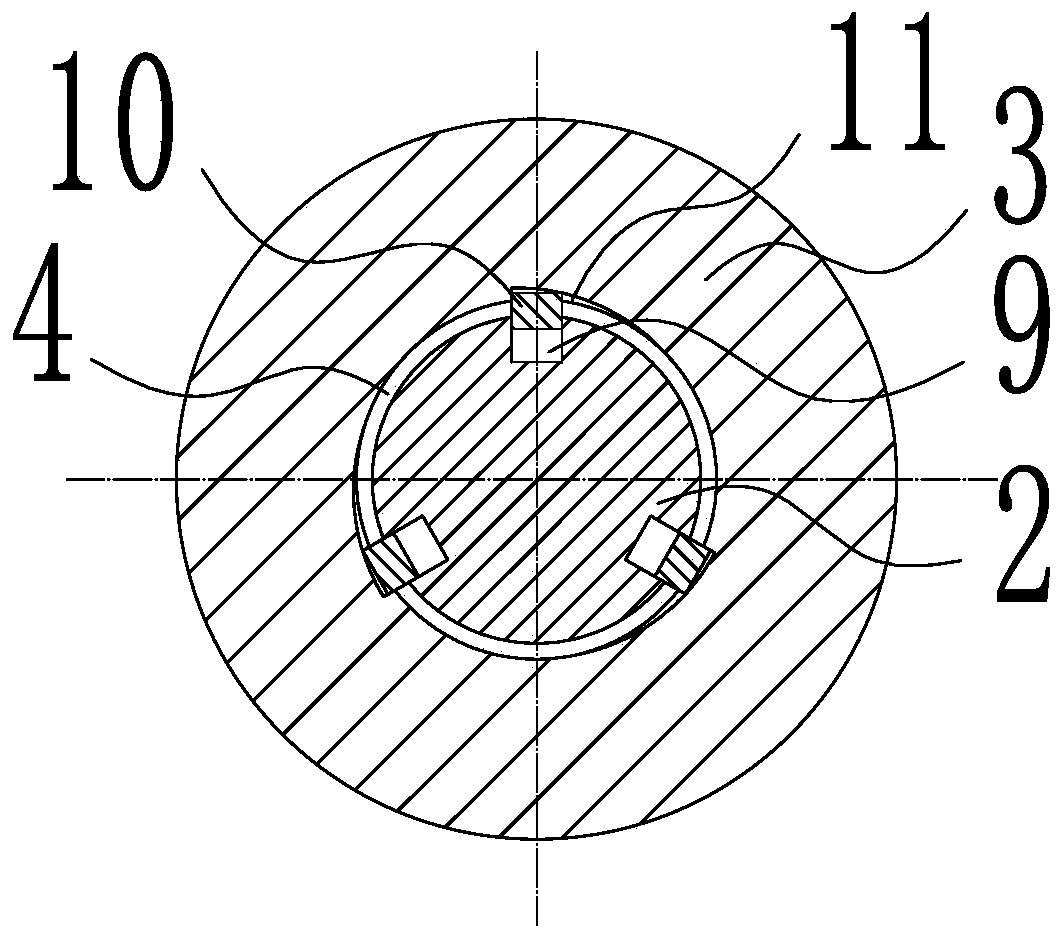

[0017] Such as figure 1 As shown, a water squeezing roller for wet etching of the present invention includes a drive wheel set 1 and a support shaft 2 arranged horizontally above the drive wheel set 1, and five sleeves connected end to end on the support shaft 2 A smooth extrusion sleeve 3, the smooth extrusion sleeve 3 is made of polyvinylidene fluoride, the roughness of its outer ring surface is 300 μm, and the support shaft 2 corresponding to the two ends of the smooth extrusion sleeve 3 The upper sleeve is fixed with a positioning sleeve 6, and the end surface of the smooth extrusion sleeve 3 corresponding to the positioning sleeve 6 has a counterbore 7, and the positioning sleeve 6 is located in the counterbore 7, and the middle hole of the smooth extrusion sleeve 3 is aligned with the A first gap 4 is formed between the support shafts 2, a second gap 8 is formed between the outer ring surface of the positioning sleeve 6 and the inner ring surface of the corresponding cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com