Water transfer printing backing paper having single-surface anti-adhesion characteristic and preparation method of water transfer printing backing paper

A water transfer printing and anti-blocking technology, applied in the printing field, can solve the problems of increasing manpower and material resources, increasing costs, etc., and achieve the effect of cost saving, simple process and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

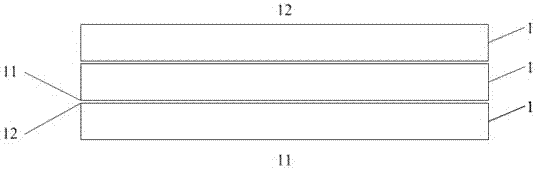

[0062] Correspondingly, the present invention also provides a method for preparing a water transfer backing paper with single-side anti-blocking properties, comprising:

[0063] 1. Provide a water transfer backing paper;

[0064] 2. Apply the anti-adhesive substance evenly on the non-printing surface of the above-mentioned water transfer backing paper to form an anti-adhesive layer, and the coating amount of the anti-adhesive substance is 2 .

[0065] It should be noted that since the non-printing surface of the water transfer backing paper will be relatively rough, when the non-printing surface is coated with an anti-adhesion layer, a higher coating amount is required to realize the anti-adhesion function, but the conventional anti-adhesion The coating amount of the substance will block the gap of the water transfer backing paper and reduce its water permeability.

[0066] In order to prevent the silicone oil substances from penetrating into the paper fibers of the bottom pa...

Embodiment 1

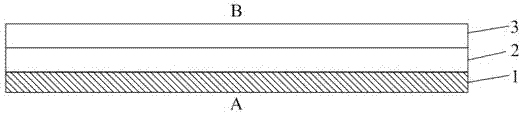

[0079] A water transfer backing paper with single-sided anti-blocking properties, comprising:

[0080] Water transfer backing paper;

[0081] The release layer located on the non-printing surface of the water transfer backing paper, the release layer is made of silicone oil, wherein the silicone oil is alkyl polyether silicone oil with a viscosity of 1500cst / 25°C.

Embodiment 2

[0083] A water transfer backing paper with single-sided anti-blocking properties, comprising:

[0084] Water transfer backing paper;

[0085] The release layer located on the non-printing surface of the water transfer backing paper, the release layer is made of silicone oil, wherein the silicone oil is amino polyether block silicone oil with a viscosity of 2000cst / 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average peel force | aaaaa | aaaaa |

| Average peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com