Industrial wastewater treatment catalytic oxidation complete equipment

A technology for catalytic oxidation and industrial wastewater, applied in textile industry wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc., it can solve the rising cost of wastewater treatment due to worker workload, increase the cleaning cycle of reaction tank, catalyst regeneration or replacement cycle and other issues to achieve the effect of improving stability and reducing cost of use

Pending Publication Date: 2017-11-17

NINGBO QINGSHUIYUAN WATER TECH

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, there is a common shortcoming in the catalytic oxidation reaction, that is, the surface activity of the catalyst cannot be effectively maintained for a long time during use.

If it is desired to keep the catalyst surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Login to View More

Abstract

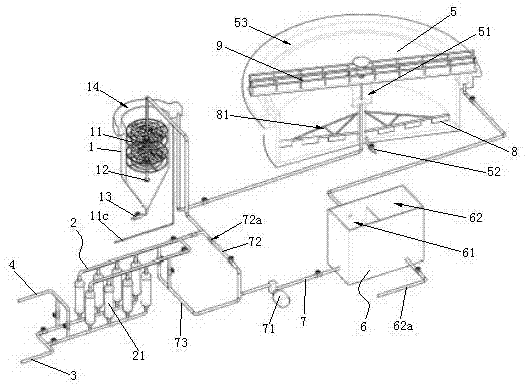

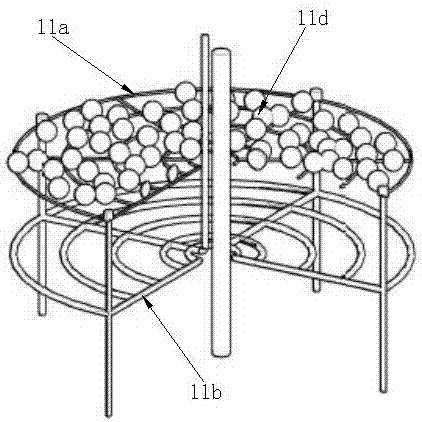

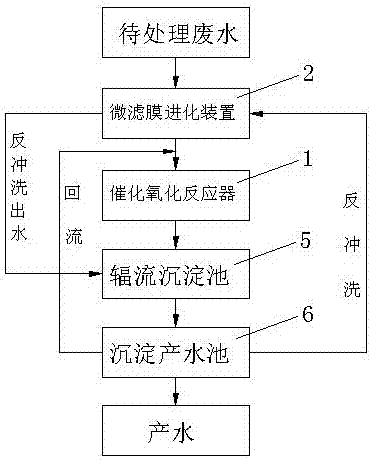

The invention discloses industrial wastewater treatment catalytic oxidation complete equipment which comprises a catalytic oxidation reactor, wherein the catalytic oxidation reactor is internally provided with a catalyst reaction rack and a water distributor; a reactor sludge outlet is formed in the lower end of the catalytic oxidation reactor; the water distributor is connected with the outlet of a micro-filtering membrane purification device; a water inlet tube and a backwash water outlet tube are connected with the inlet of the micro-filtering membrane purification device; a water storage tank at the upper end of the catalytic oxidation reactor is connected with a settling pond dosing zone of a settling pond; a settling pond sludge outlet is connected with the bottom of the settling pond; a water generation tank at the upper end of the settling pond is communicated with a settling water generation tank; a backflow water tank and an effluent tank are arranged inside the settling water generation tank; the backflow water tank is connected with the outlets of the water distributor and the micro-filtering membrane purification device respectively; a generated water outlet tube is connected with the effluent tank. The equipment has the advantages that the structure is reasonable, catalytic oxidation is combined with the settling pond, and the service life is long.

Description

technical field [0001] The invention relates to the technical field of industrial wastewater treatment, in particular to a complete set of catalytic oxidation equipment for industrial wastewater treatment. Background technique [0002] Catalytic oxidation technology is widely used in industrial wastewater treatment because it can efficiently degrade substances that are difficult to degrade by biological methods and can be applied to scenarios where microorganisms cannot be applied. [0003] At present, there is a common shortcoming in the catalytic oxidation reaction, that is, the surface activity of the catalyst cannot be effectively maintained for a long time during use. If it is desired to keep the catalyst surface active for a long time, it is necessary to increase the cleaning cycle of the reaction tank and the regeneration or replacement cycle of the catalyst, which brings about the problems of worker workload and wastewater treatment cost increase. Contents of the i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/04C02F103/30

CPCC02F9/00C02F2103/30C02F1/24C02F1/444C02F1/725C02F1/52C02F7/00

Inventor 王红杰逯庆国周宇松焦志建刘全利李亮

Owner NINGBO QINGSHUIYUAN WATER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com