Measuring method of cage pocket of thrust self-aligning roller bearing

A technology of thrust self-aligning rollers and bearing cages, applied in the direction of mechanical diameter measurement, etc., can solve the problems of inability to quantitatively analyze dimensional errors, scratches on the bottom of pocket holes, and low inspection efficiency, so as to facilitate proofreading and improve job replacement Efficiency, the effect of improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] Such as Figure 2-7 As shown, a method for measuring the center diameter of the cage of a thrust spherical roller bearing includes the following steps:

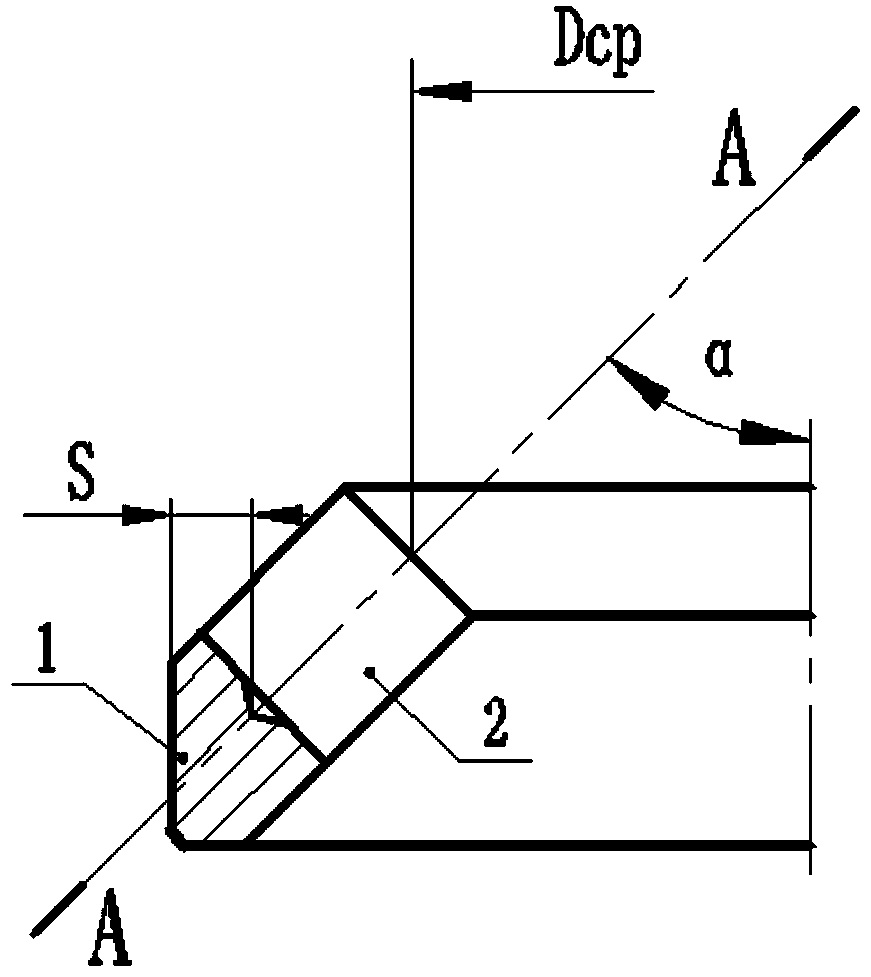

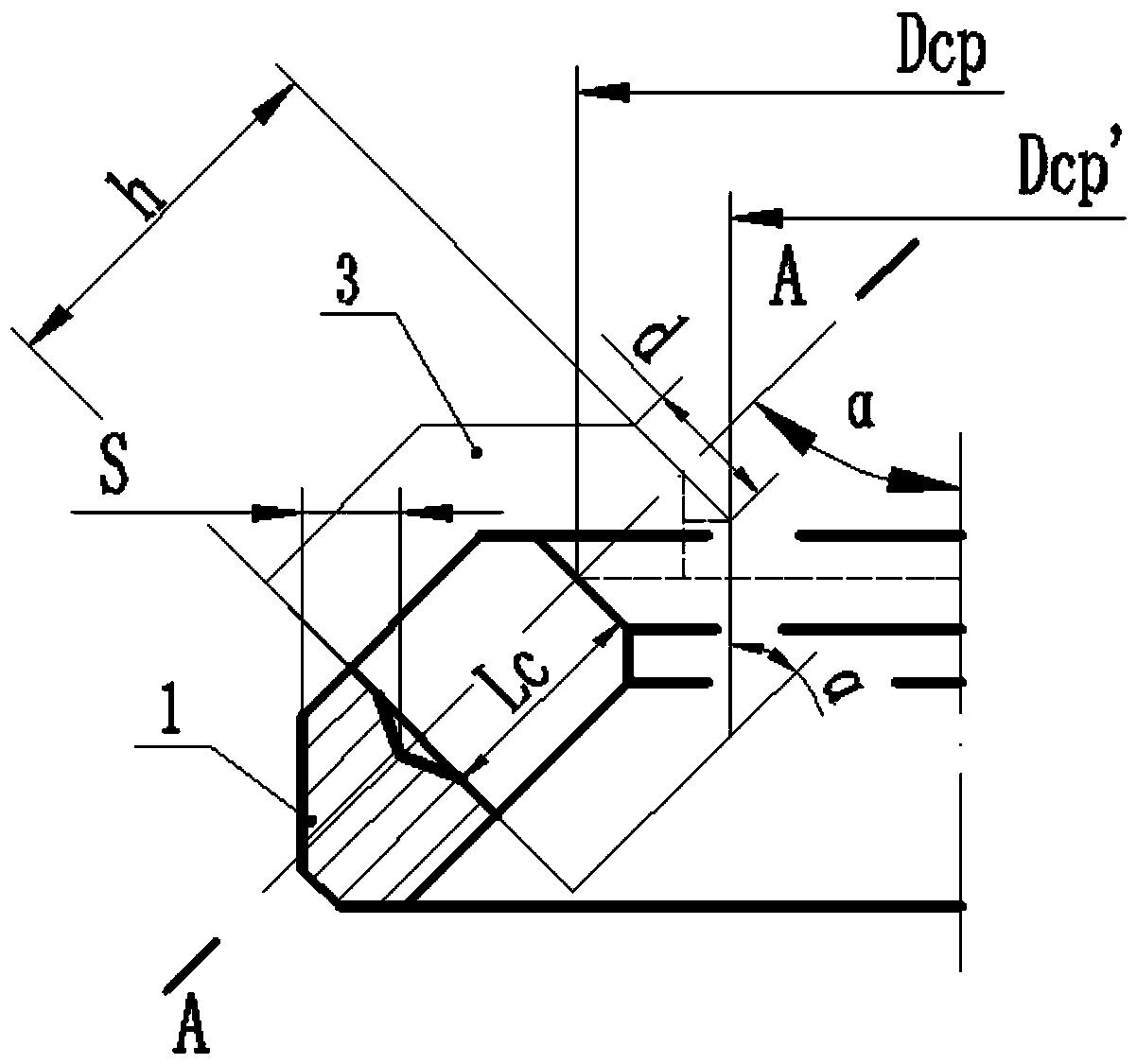

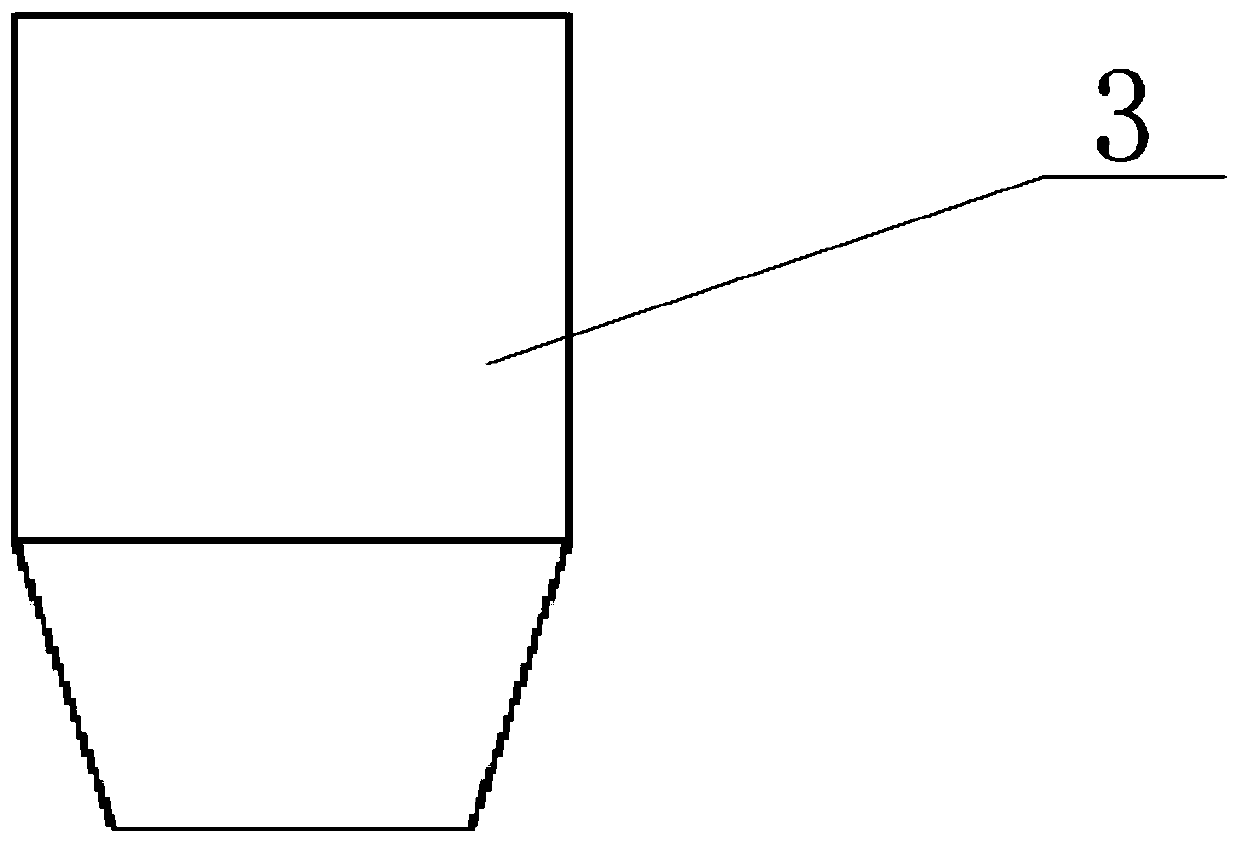

[0038] ① Install a measuring column 3 in the two pockets 2 of the longest chord of the measured cage 1, the measuring column 3 is composed of a cylinder at one end and a truncated cone at the other end. The longitudinal section is an isosceles trapezoid and the inclination angle of the waist of the trapezoid is the same as the inclination angle α of the pocket hole. Cooperate, the central axis of measuring column 3 coincides with the central axis of pocket hole 2;

[0039] ②Measure the distance between the circular platforms of the two measuring columns 3 with a special-purpose caliper 4. The special-purpose caliper includes a main ruler 41, a measuring cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com