A test device for dynamic and static performance of oil film bearings

An oil film bearing and test device technology, applied in mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of lack of dynamic performance testing, incomplete performance testing of oil film bearings, lack of performance testing of oil film bearings, etc. The effect of reducing the amount of axial movement and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

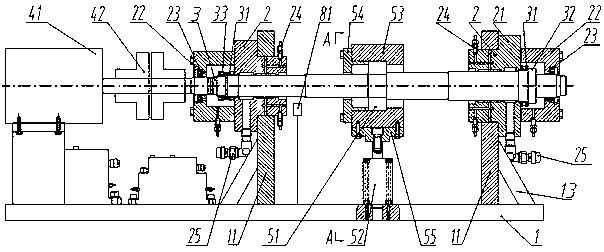

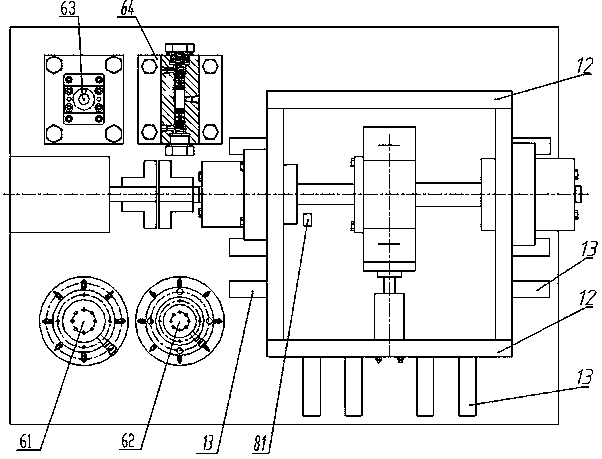

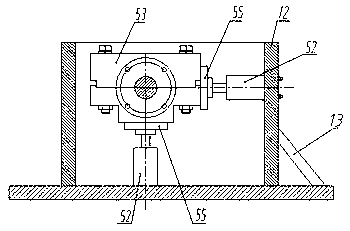

[0050] see figure 1 , a dynamic and static performance test device for oil film bearings, comprising a test bench body 1, two bearing seats 11 are arranged at intervals on the test bench body 1, and the two bearing seats 11 are connected to the test bench body 1 by bolts and positioned by positioning pins; The two bearing seats 11 are respectively provided with bearing installation holes for installing the oil film bearing 2, the bearing installation holes on the two bearing seats 11 are coaxial and the axes are set horizontally; the two bearing installation holes are respectively equipped with an oil film Bearing 2, the oil film bearing 2 is an oil film bearing with four oil chambers, and each oil chamber is correspondingly connected with an oil pipe joint 24; the two oil film bearings 2 are equipped with a test shaft 3 for internal clearance rotation cooperation.

[0051] Wherein, the oil film bearing 2 is provided with a flange 21 around the end face of one end, and the fla...

Embodiment 2

[0063] On the basis of the first embodiment, the oil film bearing 2 or the different connection modes of the oil film bearing 2 are replaced.

[0064] The outer circle of the oil film bearing 2 is consistent, no flange 21 is provided, and the oil film bearing 2 is installed in the bearing mounting holes on the two bearing seats 11 with an interference fit, so that the axial movement of the oil film bearing 2 can be effectively avoided; correspondingly, There is no need to set one-way thrust ball bearing 31, annular step 32, shaft cover 33 on the test shaft 3, so the structure of the test shaft 3 is simpler, but the installation and disassembly of the oil film bearing 2 is relatively difficult.

Embodiment 3

[0066] On the basis of the first embodiment, the oil film bearing 2 or the different connection modes of the oil film bearing 2 are replaced.

[0067] The outer circle of the oil film bearing 2 is the same, and the flange 21 is not provided. A ferrule is set on one end of the oil film bearing 2 and connected by a fastener to replace and achieve the function of the flange 21. In this way, the shape of the oil film bearing 2 is more demanding. Low, easy to process, but lack of integrity, the long-term rotation of the variable frequency motor 41 will easily lead to the loosening of the ferrule, which will affect the detection accuracy. It is necessary to check the fastening situation of the ferrule and the oil film bearing 2 frequently and tighten it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com