Cement base pipe mechanical property testing method

A test method, cement-based technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unusable, increase wall thickness, and directly measure the bending strength of tubular samples, so as to save testing costs, Save test time and apply to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will be described in detail with reference to the drawings and specific embodiments.

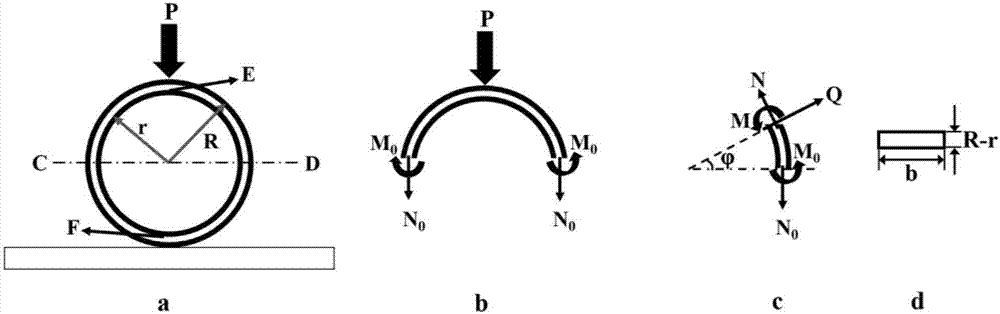

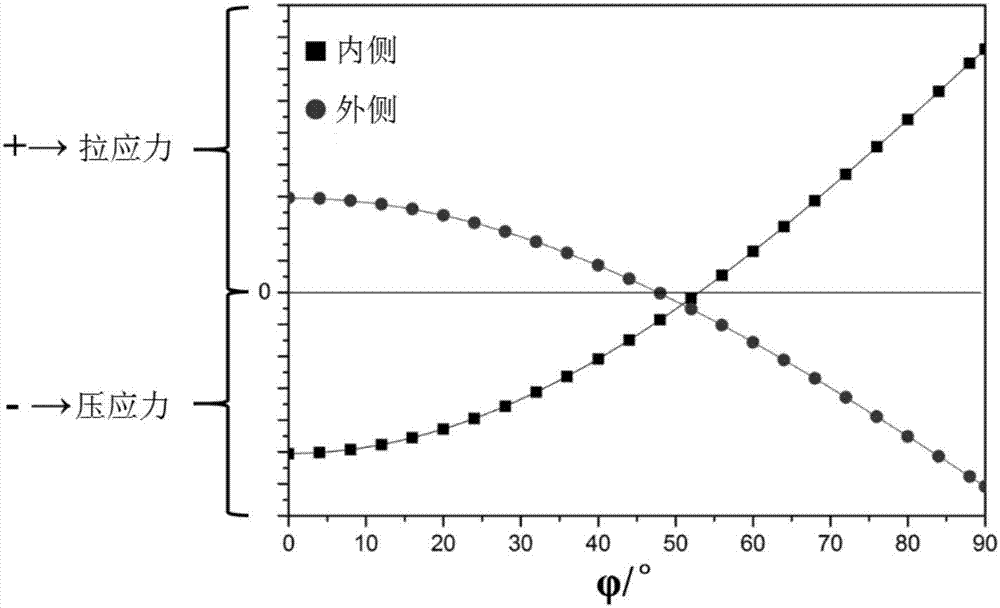

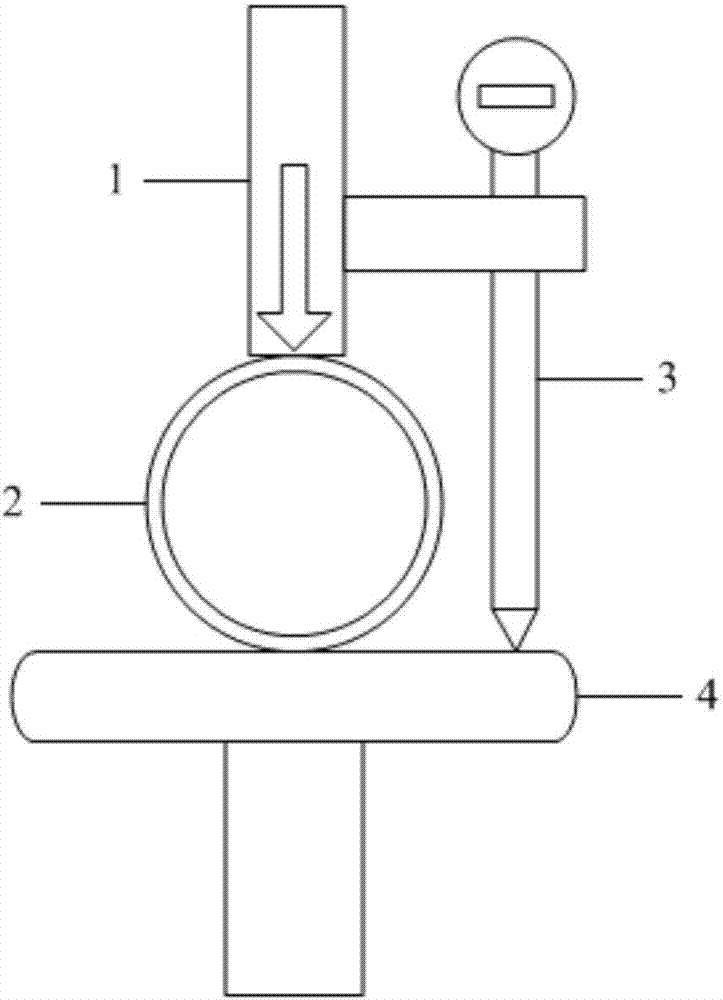

[0040] The invention provides a method for testing the mechanical properties of cement-based pipes. Aiming at the existing technology—the gap ring method, it can only measure thin-walled pipe samples and defects that affect the original residual internal stress distribution of the samples. This method is especially suitable for Cement-based pipes, and can also be popularized and applied to the measurement fields of elastic modulus and bending strength of other pipes, including resin-based pipes and ceramic pipes with low stiffness. The method comprises: applying a radial compression load to the cement-based pipe sample until the cement-based pipe sample breaks, and calculating the elastic modulus and bending strength of the cement-based pipe sample ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com