Water-collecting degradable mulching film and preparation method thereof

A technology for degrading plastic film and water collection, applied in the fields of botanical equipment and methods, plant protection, application, etc., can solve the problems of poor moisture retention of the degradable plastic film, unsuitable for application in arid and semi-arid areas, etc., to achieve cheap raw materials, improve use efficiency and The effect of stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

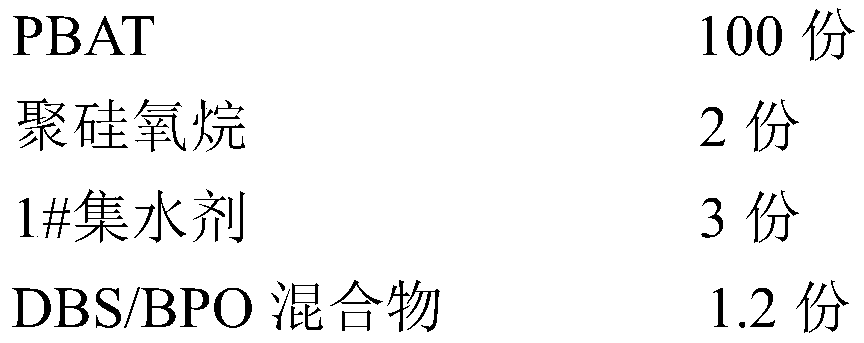

Embodiment 1

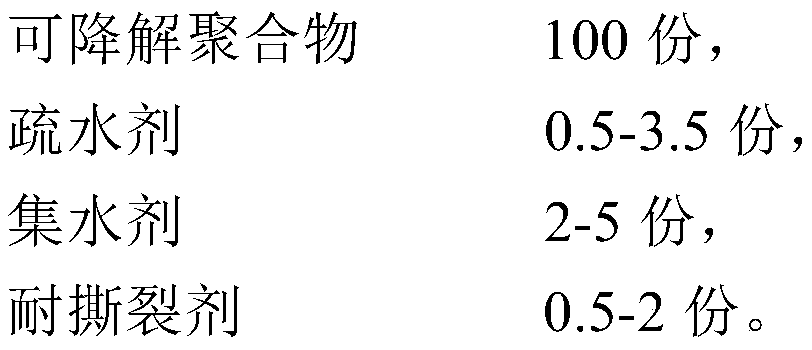

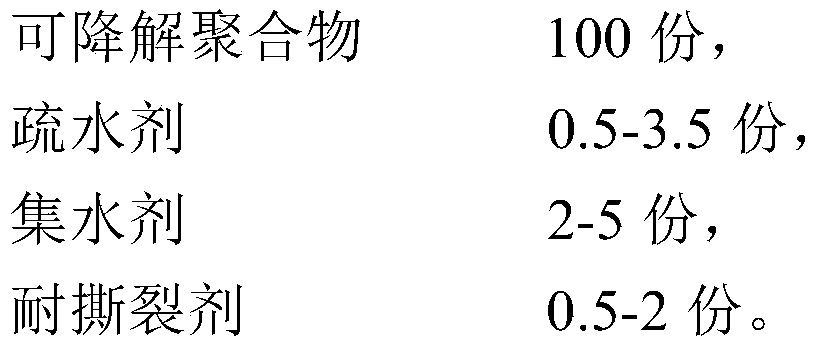

[0046] The water-collecting and degradable plastic film is composed of the following components by mass:

[0047]

[0048] Wherein, the mixing ratio of DBS / BPO mixture is DBS:BPO=4:7;

[0049] 1# water-collecting agent is surface-modified mica powder with a particle size of 15 μm, prepared according to the following steps:

[0050] S1: Mix sodium silicate, polyacrylamide, hexamethylenetetramine, ethyl acetate, aluminum phosphate and polyoxyethylene ether in a weight ratio of 55:10:18:12:1.5:8.5 to prepare a surface Modifier;

[0051] S2: In a stirring state, spray the surface modifier obtained in S1 onto the surface of the hydrophilic powder filler to obtain a spray powder; wherein, the spraying amount of the surface modifier is 1.5% of the mass of the hydrophilic powder filler;

[0052] S3: Stir and dry the spray powder obtained in S2 at 40°C until it is fluffy and not agglomerated to obtain a fluffy powder;

[0053]S4: The fluffy powder obtained in S3 was heated and re...

Embodiment 2

[0060] The water-collecting and degradable plastic film is composed of the following components by mass:

[0061]

[0062] Wherein, the mixing ratio of the PBAT / PBS mixture is PBAT:PBS=8:2; the mixing ratio of the P-M-DBS / DCP mixture is P-M-DBS:DCP=1:2.

[0063] 2# water-collecting agent is surface-modified talcum powder with a particle size of 10 μm, which is prepared according to the following steps:

[0064] S1: Mix sodium silicate, polyacrylamide, hexamethylenetetramine, ethyl acetate, aluminum phosphate and polyoxyethylene ether in a weight ratio of 51:11:16:9:1.2:9 to prepare a surface Modifier;

[0065] S2: In a stirring state, spray the surface modifier obtained in S1 onto the surface of the hydrophilic powder filler to obtain a spray powder; wherein, the spraying amount of the surface modifier is 1% of the mass of the hydrophilic powder filler;

[0066] S3: Stir and dry the spray powder obtained in S2 at 30°C until it is fluffy and not agglomerated to obtain a fl...

Embodiment 3

[0074] The water-collecting and degradable plastic film is composed of the following components by mass:

[0075]

[0076] Wherein, the mixing ratio of PBAT / PLA mixture is PBAT:PLA=7:3; the mixing ratio of P-Cl-DBS / DTBP mixture is P-Cl-DBS:DTBP mixture=3:5.

[0077] 3# water-collecting agent is surface-modified glass microspheres with a particle size of 25 μm, prepared according to the following steps:

[0078] S1: Mix sodium silicate, polyacrylamide, hexamethylenetetramine, ethyl acetate, aluminum phosphate and polyoxyethylene ether in a weight ratio of 53:10:17:10:1.5:7.5 to prepare a surface Modifier;

[0079] S2: In a stirring state, spray the surface modifier obtained in S1 onto the surface of the hydrophilic powder filler to obtain a spray powder; wherein, the spraying amount of the surface modifier is 0.5% of the mass of the hydrophilic powder filler;

[0080] S3: Stir and dry the spray powder obtained in S2 at 30°C until it is fluffy and not agglomerated to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com