Chemical fertilizer and preparation method thereof

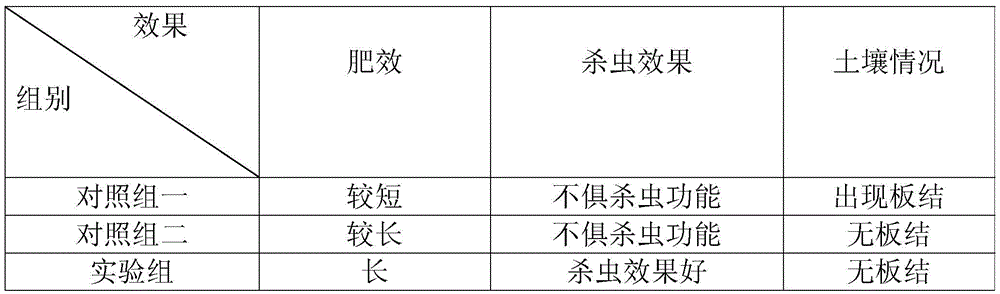

A chemical fertilizer and raw material technology, applied in the field of chemical fertilizer and its preparation, can solve the problems of short storage time, lack of insecticide and sterilization, etc., achieve the effect of bactericidal fertilizer, good insecticidal effect, and improve fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Mix 15 parts of ammonium polyphosphate, 20 parts of potassium nitrate, 10 parts of potassium dihydrogen phosphate, and 14 parts of ammonium sulfate into an iron tank, feed steam and stir at the same time, so that the raw materials are dissolved, and the stock solution is obtained for later use;

[0029] 2) Mix 8 parts of liquid pesticide, 6 parts of bentonite, 1 part of suspending agent, 2 parts of anti-crystallization agent, and 3 parts of antifreeze, put them into an emulsifier and stir evenly, and set aside;

[0030] 3) Put 1 part of 萹落, 2 parts of Toosendan, 3 parts of wax gourd flesh, and 3 parts of guanyin into a steamer and keep it at 90-95°C for 15-20 minutes, then take it out and soak it in cold water for 10- After 15 minutes, put the soaked raw materials into a grinder and grind them into a paste, then set aside;

[0031] 4) Put 4 parts of Brahman honey locust, 1 part of green weed, and 5 parts of catalpa bark into the oven and bake at 130-150°C for 10-15 m...

Embodiment 2

[0037] 1) Mix 17.5 parts of ammonium polyphosphate, 22.5 parts of potassium nitrate, 12.5 parts of potassium dihydrogen phosphate, and 16 parts of ammonium sulfate into an iron tank, feed steam and stir at the same time, so that the raw materials are dissolved, and the stock solution is obtained for later use;

[0038] 2) Mix 9 parts of liquid pesticide, 7 parts of bentonite, 2 parts of suspending agent, 3 parts of anti-crystallization agent, and 4 parts of antifreeze, put them into an emulsifier and stir evenly, and set aside;

[0039] 3) Put 1.5 parts of watermelon fruit, 2.5 parts of toosendan, 4.5 parts of wax gourd pulp, and 4 parts of peony into a steamer and keep it at 90-95°C for 15-20 minutes, then take it out and soak it in cold water for 10- After 15 minutes, put the soaked raw materials into a grinder and grind them into a paste, then set aside;

[0040]4) Put 5 parts of brahmana honey locust, 2 parts of green weed, and 6 parts of catalpa wood bark into the oven an...

Embodiment 3

[0046] 1) Mix 20 parts of ammonium polyphosphate, 25 parts of potassium nitrate, 15 parts of potassium dihydrogen phosphate, and 18 parts of ammonium sulfate into an iron tank, feed in steam and stir at the same time, so that the raw materials are dissolved, and the stock solution is obtained for later use;

[0047] 2) Mix 10 parts of pesticide, 8 parts of bentonite, 3 parts of suspending agent, 4 parts of anti-crystallization agent, and 5 parts of antifreeze, put them into an emulsifier and stir evenly, and set aside;

[0048] 3) Put 2 parts of watermelon, 3 parts of toosendan, 6 parts of wax gourd flesh, and 5 parts of peony into a steamer and keep it at 90-95°C for 15-20 minutes, then take it out and soak it in cold water for 10- After 15 minutes, put the soaked raw materials into a grinder and grind them into a paste, then set aside;

[0049] 4) Put 6 parts of brahmana honey locust, 3 parts of green weed, and 7 parts of catalpa bark into the oven and bake at 130-150°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com