Dynamic sensor based broken stone particle simulation test system and method

A simulation test and sensor technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of restricting the development of the theory related to dynamic deformation of scattered bodies, lack of meso-observation methods, etc., and achieve the effect of flexible use, small size, and reduced interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

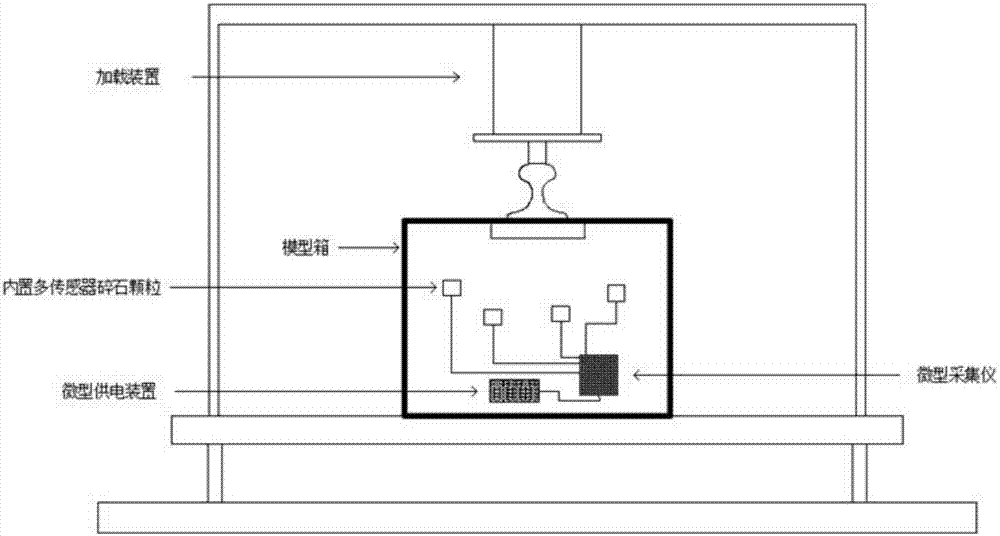

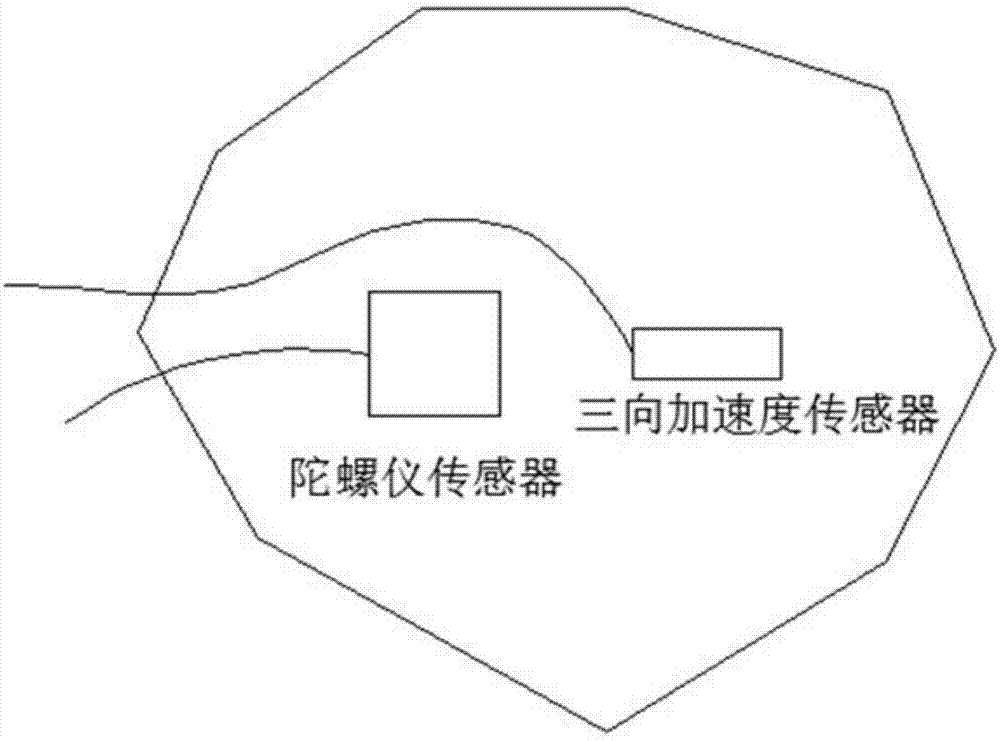

[0030] The purpose of the present invention is to provide a simulation test system based on dynamic sensor crushed stone particles. By implanting multiple sensors in the crushed stone particles, the real-time monitoring of the movement process of a single crushed stone particle under the action of power can be revealed from a microscopic point of view. The dynamic characteristics of bulk materials, in order to achieve this goal, the following technical solutions are adopted, such as figure 1 The system structure shown includes:

[0031] Model test box: It is a rectangular box, which is filled with a scale gravel model to simulate the roadbed, and the upper surface is equipped with rails;

[0032] High-frequency loading device: including a test bench, a frame set on the test bench, and an exciter set on the frame and in contact with the rails...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com