A kind of cutting machine circular blade and its cutting method

A cutting method and cutting machine technology, which are applied to shearing devices, knives for shearing machine devices, metal processing equipment, etc., can solve the problems of round blades not being able to remove burrs, etc., achieve intuitive distance, improve efficiency, and improve general use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

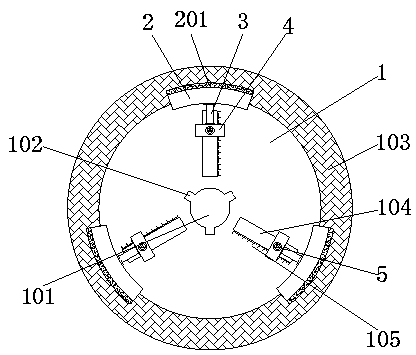

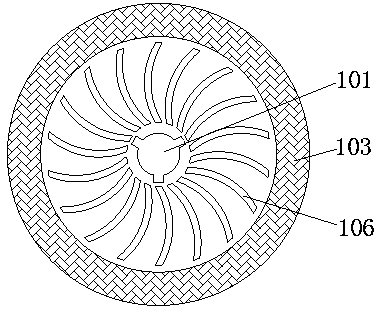

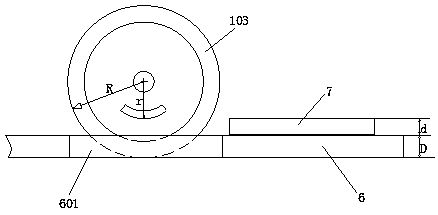

[0027] as shown in the picture Figure 1 to Figure 2 As shown, a cutting machine circular blade includes a circular cutterhead 1, and the circular cutterhead 1 is provided with a shaft hole 101; the outer edge of the circular cutterhead 1 is fixedly provided with a circle of cutting edges 103; the circular cutterhead 1 There are several deburring knives 2 that are detachably connected to the round cutter head 1 distributed on the front of the front face; There is an outwardly convex arc-shaped burr edge 201; the burr knife 2 is slidably connected with the disc surface of the circular cutter head 1 along the radial direction of the circular cutter head 1 through a sliding mechanism, and can be positioned on the circular cutter head 1 by a positioning mechanism. up positioning.

[0028] The cutting edge 103 on the circular cutterhead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com