Tooth alignment device for grinding teeth of worm

A technology for grinding teeth and worms, which is applied to gear tooth manufacturing devices, gear teeth, gear cutting machines, etc., to achieve the effects of reasonable structural design, convenient use, and improved efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

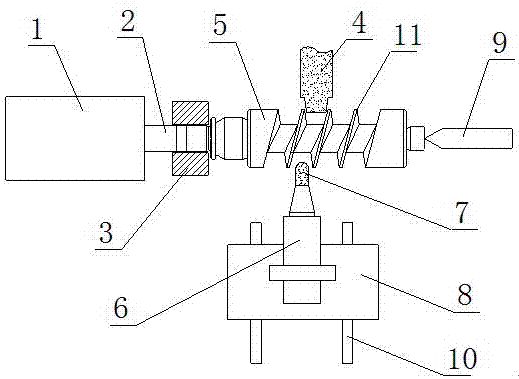

[0011] For specific examples, see figure 1 , a gear-aligning device for worm grinding, comprising a motor 1, a tooth-aligning tool 6, a top 9 and a grinding wheel 4, a chuck 3 is provided on the rotating shaft 2 of the motor 1, and a top 9 is provided on the corresponding chuck 3, so A grinding wheel 4 is provided on one side of the clamp head 3 and the top 9 of the worm gear grinding gear alignment device, and a gear alignment tool 6 is provided on the other side of the upper chuck 3 and the top tip 9 of the worm gear grinding gear alignment device. The tooth-aligning tool 6 is provided with a tooth-aligning protruding rod 7, the tooth-aligning tool 6 is fixed on a servo motor 8, the servo motor 8 is arranged on the guide rail 10, and the servo motor 8 can drive the tooth-aligning tool 6 along the guide rail 10 slides, and the top of the pair of teeth protruding rods 7 is arc-shaped.

[0012] The present invention designs a worm grinding gear aligning device, the worm grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com