Hydraulic energy-storing press machine

A hydraulic energy storage and press technology, applied in the field of presses, can solve the problems of slow pressing speed, low pressure and high energy consumption, and achieve the effects of fast pressure releasing, increasing pressing speed and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

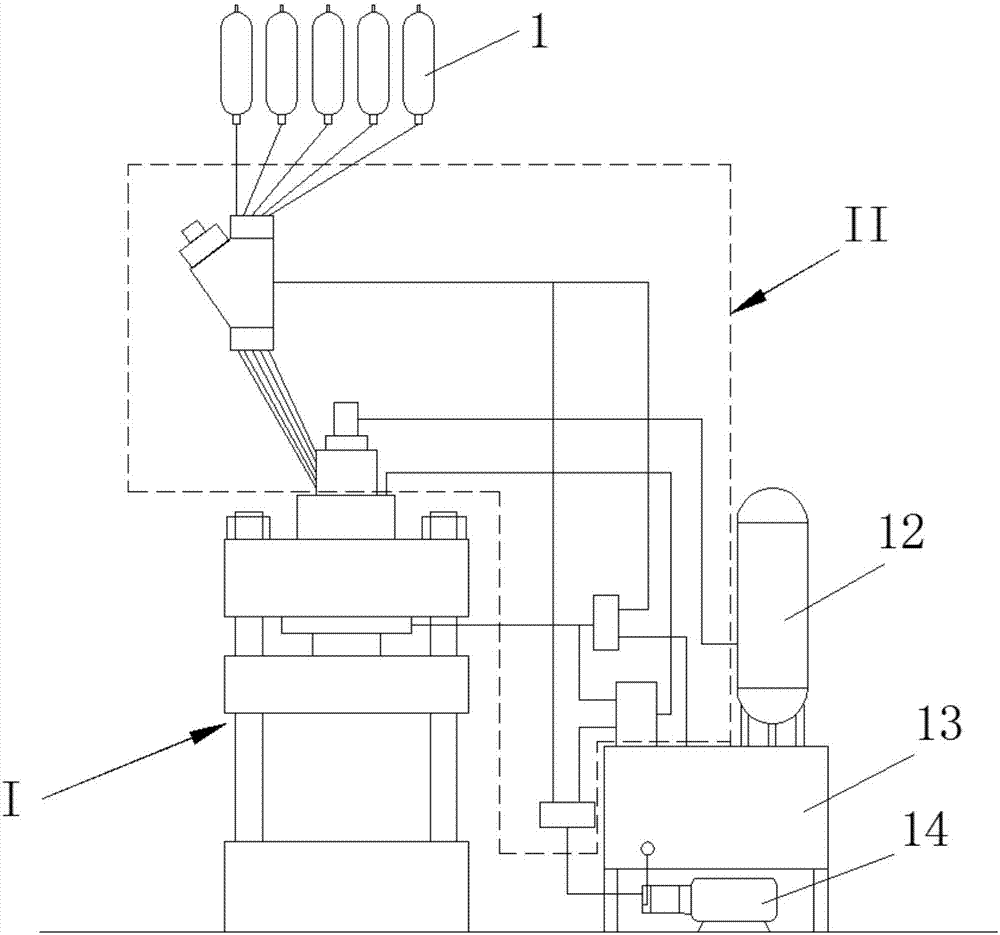

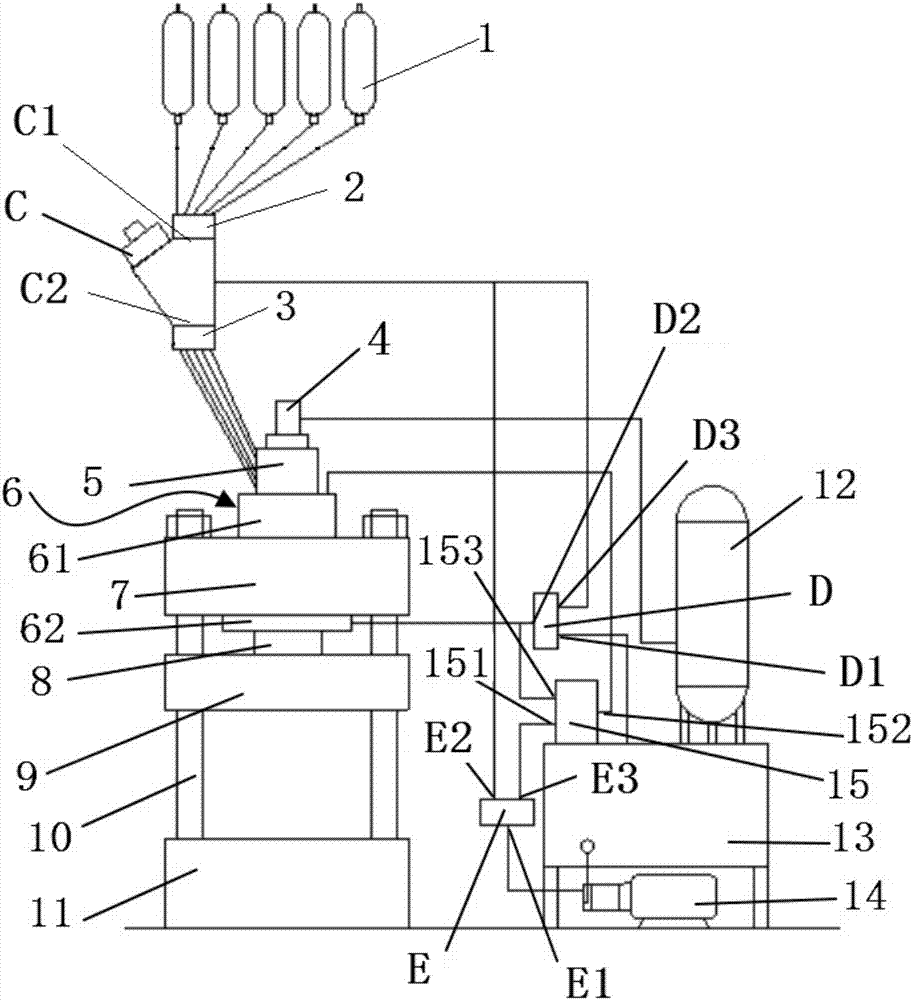

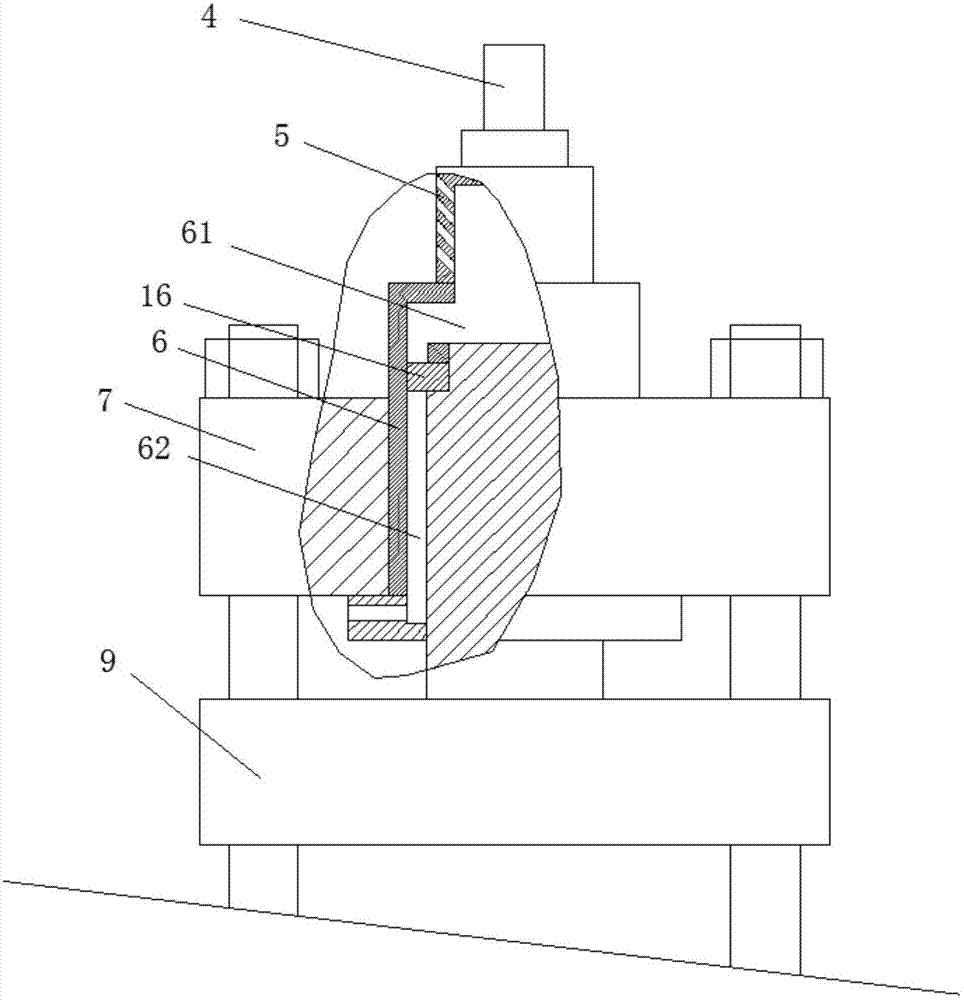

[0050] figure 1 It is a schematic structural diagram of a hydraulic accumulator press according to an embodiment of the present invention. The present invention provides a hydraulic accumulator press, which generally includes: an air storage tank 12, an oil tank 13, a hydraulic oil pump 14, an accumulator 1, a press body I and a hydraulic valve assembly II. Among them, the oil tank 13 is used to provide hydraulic oil. The hydraulic oil pump 14 has an oil inlet and an oil outlet, and the oil inlet of the hydraulic oil pump 14 is connected to the oil tank 13 for pumping hydraulic oil. The accumulator 1 is used to store and release energy. The press body 1 is used to provide a pressing place for the workpiece and to press the workpiece. The hydraulic valve assembly II is connected with the air storage tank 12, the press main body I, the hydraulic oil pump 14, the oil tank 13 and the accumulator 1, so as to realize the supply of the hydraulic oil pump 14 to the accumulator 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com