Film peeling device for light guide plates

A film device and light guide plate technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of low work efficiency, dirty product surface, unfavorable processing, etc., to improve the success rate of film tearing and ensure Effect of surface quality and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

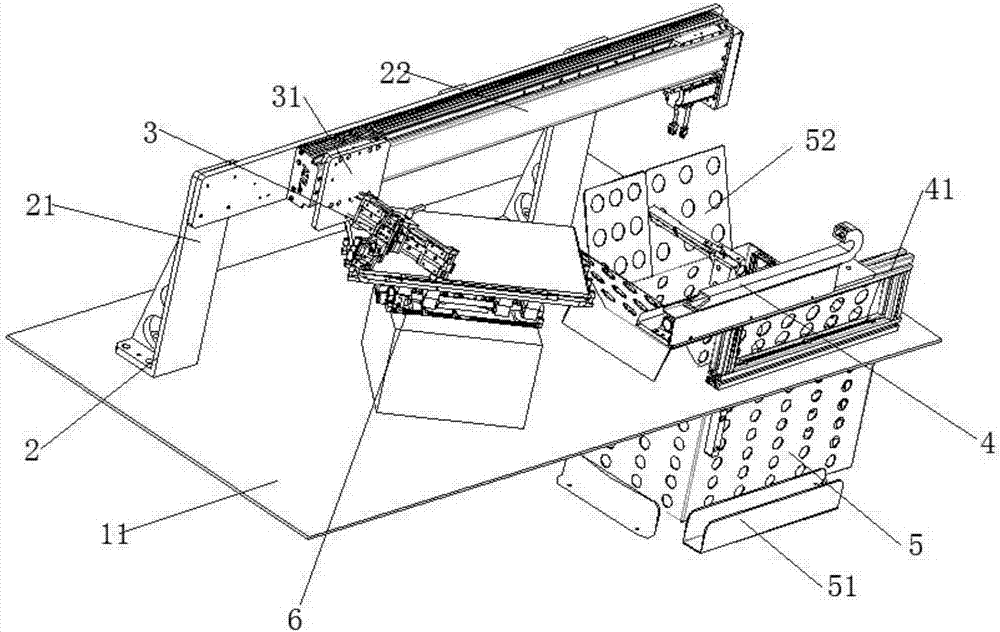

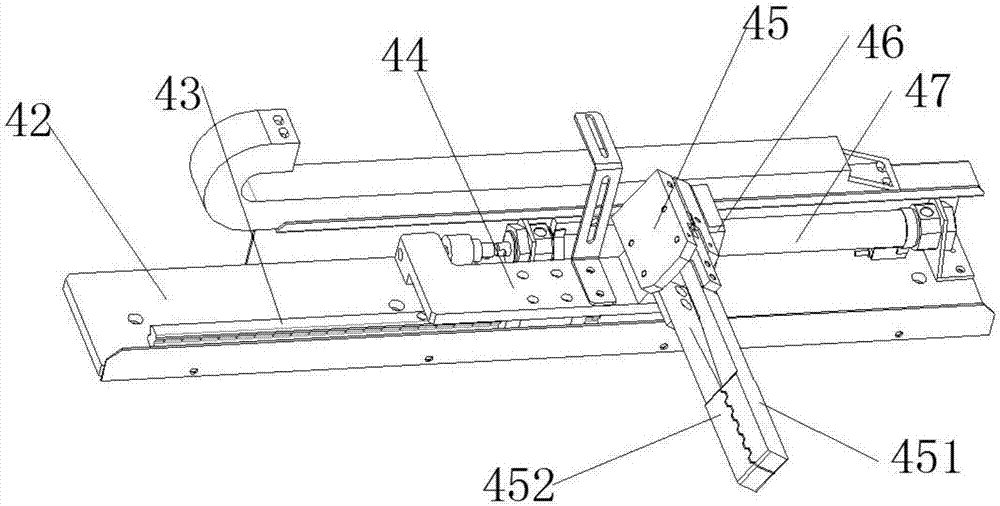

[0022] refer to figure 1 , figure 2 , a film tearing device for a light guide plate, comprising a film tearing mechanism 3, a film removing mechanism 4, a carrying mechanism 2, a material receiving mechanism, a substrate 1, and a correction platform 6, the film tearing mechanism 3 is connected to the carrying mechanism 2, and the correction The platform 6 is located below the film tearing mechanism 3, the receiving mechanism is arranged at the opening of the substrate 1, and the film removing mechanism 4 is located above the receiving mechanism;

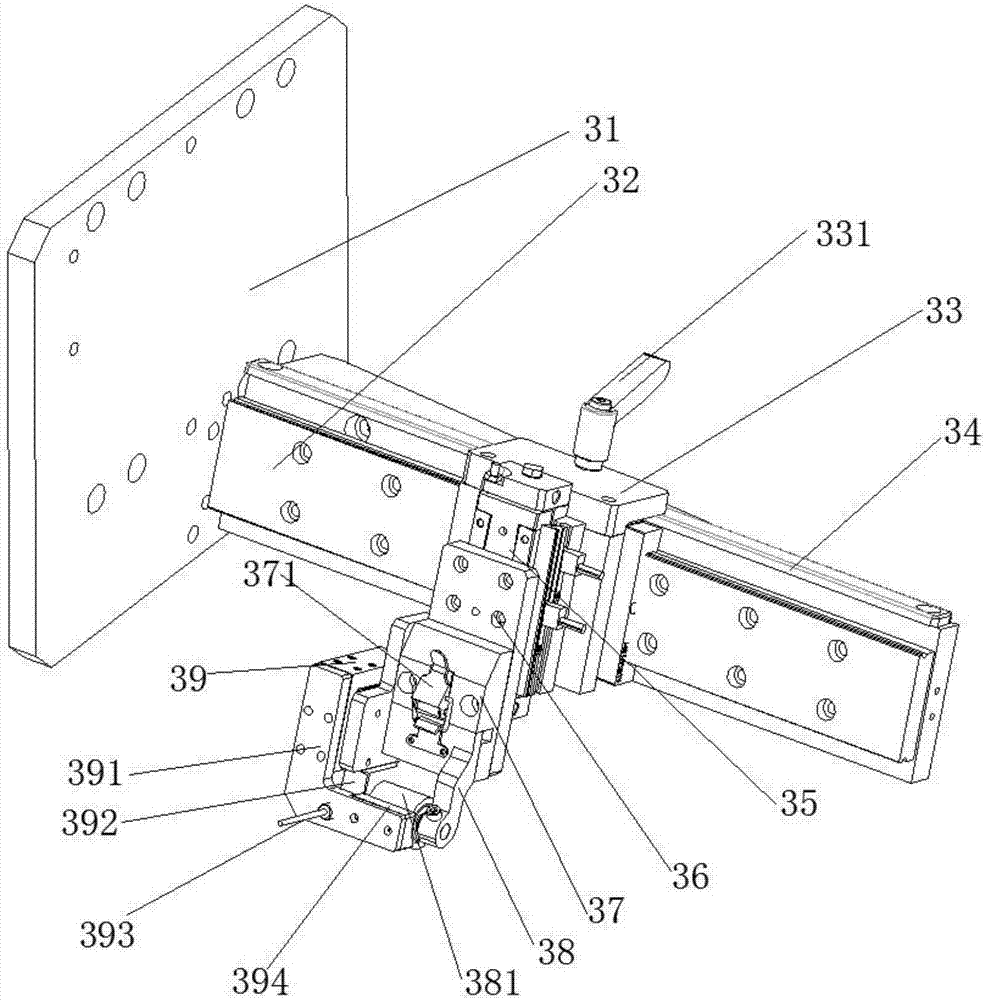

[0023] The film tearing mechanism 3 includes a fixed plate 31, a horizontal plate 34, a film tearing slide rail 32, a first slider 33, a second slider 36, a mounting block 37, a roller frame 38, a film tearing wheel 381 and a film gripper, The fixed part is connected with the carrying mechanism 2, the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com