Electric bidirectional shoe-type hopper on conveyor

A conveyor and hopper technology, applied in the field of two-way shoe hoppers, can solve the problems of increasing the number of equipment, easily limited installation space, and increasing the total cost of the project, and achieve the effect of simple and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

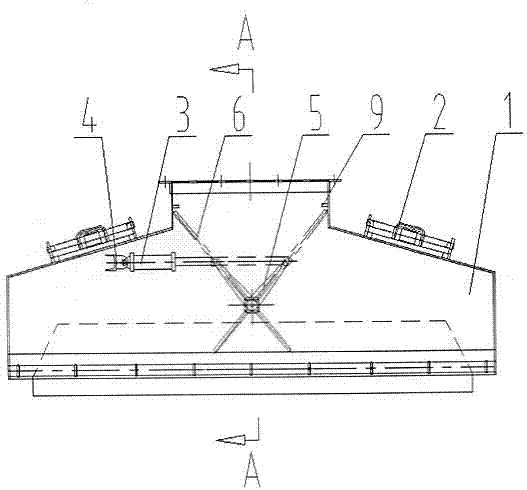

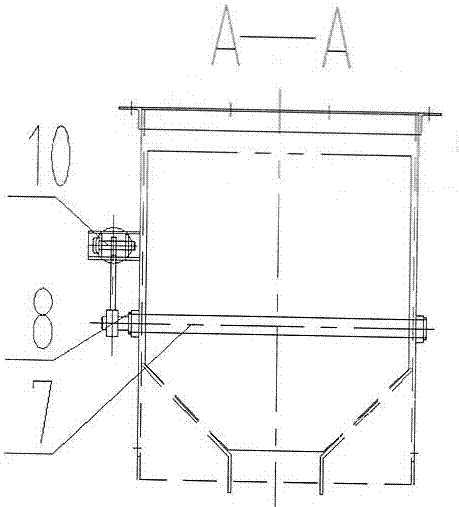

[0008] This technical solution can realize two-way diversion of materials, and solve the problem of limited installation space between conveying equipment, thereby reducing the number of equipment, reducing production and installation costs, and improving the use efficiency of equipment. Such as figure 1 As shown, the head of the two-way hopper body 1 has a feed port directly connected to the discharge port of the upstream equipment, and the two sides of the two-way hopper body feed port are provided with observation windows 2, which is convenient for observing the operation status of the material falling into the hopper. The support 4 is welded on the inner wall of the two-way hopper body, and the single-ear cylinder 3 is fixed on the cylinder support with a pin shaft, which can rotate freely up and down 180°. The front end telescopic shaft of the single-ear cylinder is connected with a connecting shaft 10, connected A crank is installed on the shaft, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com