Double-control angle type safety valve

A safety valve and dual control technology, applied in the field of safety valves, can solve problems such as damage to the system, and achieve the effect of avoiding safety accidents, avoiding economic losses and ensuring industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

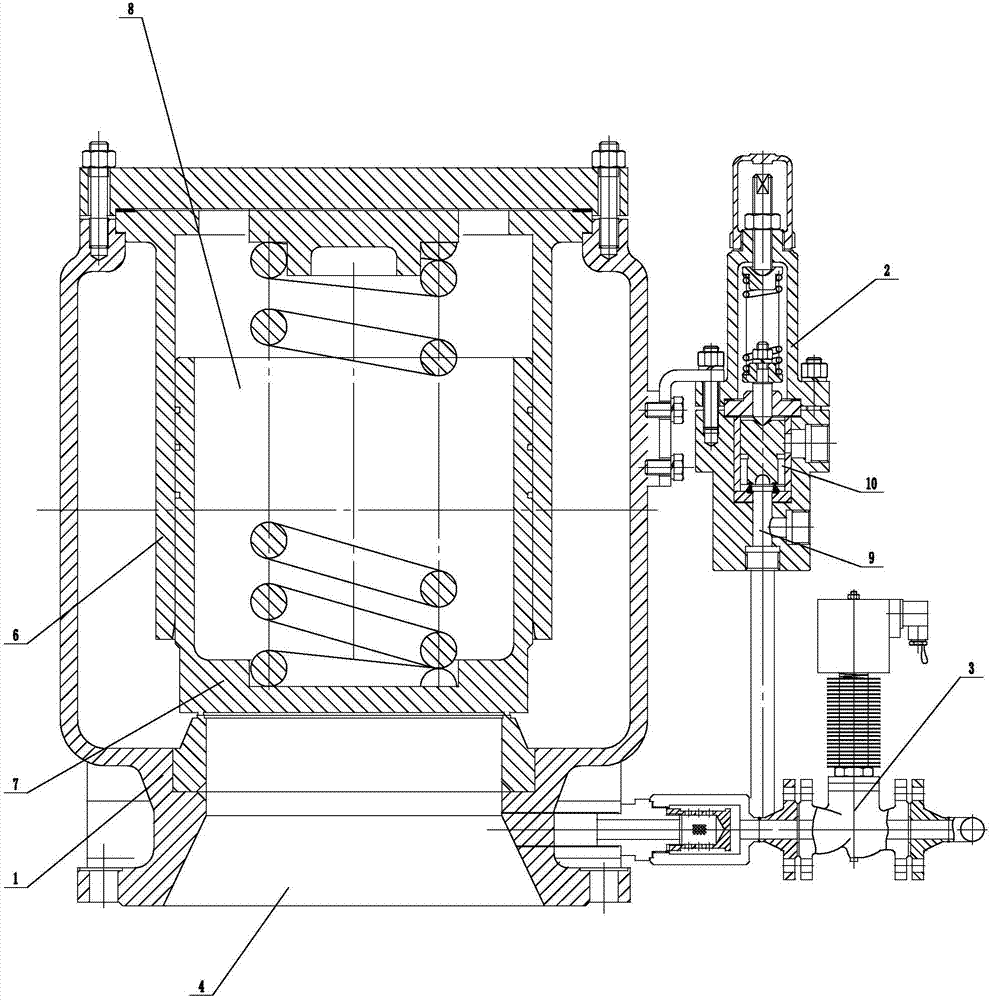

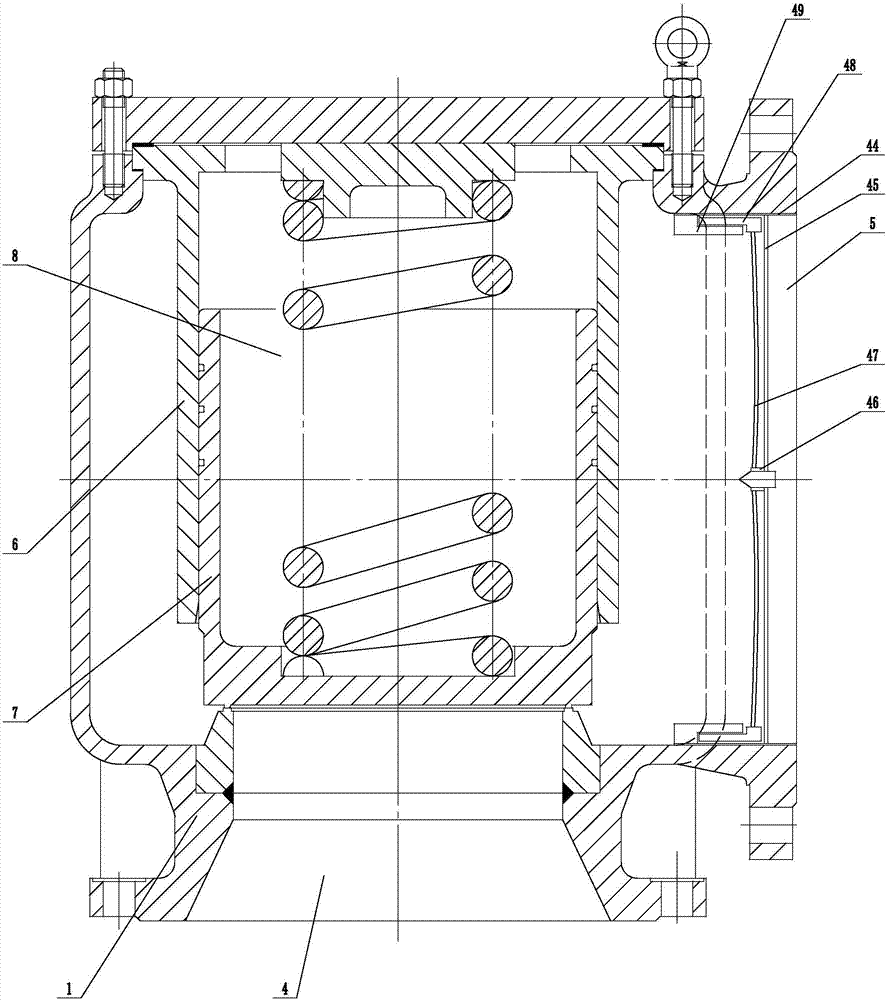

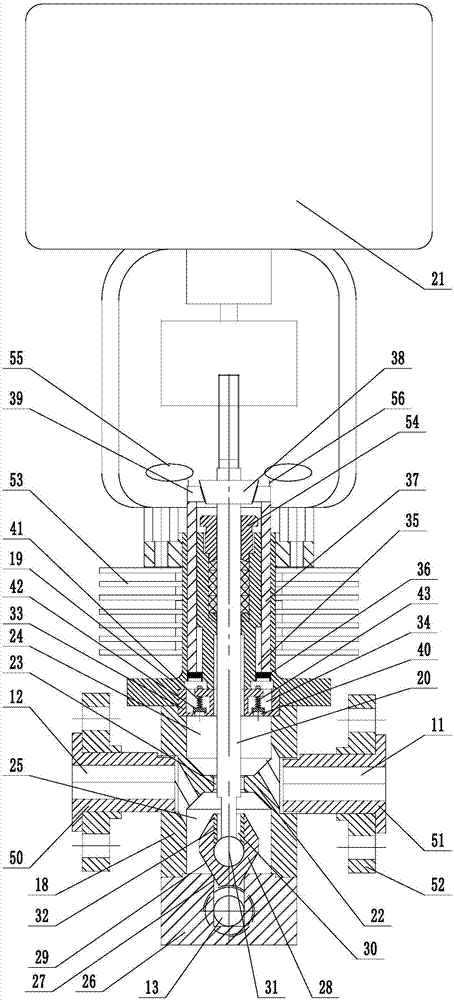

[0025] Example: A dual-control angle safety valve (see attached Figure 1 to 6 ), including the main valve 1, the mechanical pilot valve 2, the electric control valve 3. The lower end of the main valve is provided with a main valve inlet 4, the right side of the main valve is provided with a main valve outlet 5, the main valve inlet axis and the main valve outlet axis are arranged vertically , The main valve inlet and the main valve outlet form an angular structure, a guide sleeve 6 is installed in the main valve, a main valve disc 7 is installed in the guide sleeve, and a main valve chamber 8 is formed above the main valve disc in the guide sleeve. A valve seat is installed near the lower end of the main valve, the inlet of the main valve is communicated with the valve seat, and the main valve clack seals against the valve seat. The mechanical pilot valve is equipped with an inlet pressure chamber 9 and a pressure relief chamber 10. The electric control valve is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com